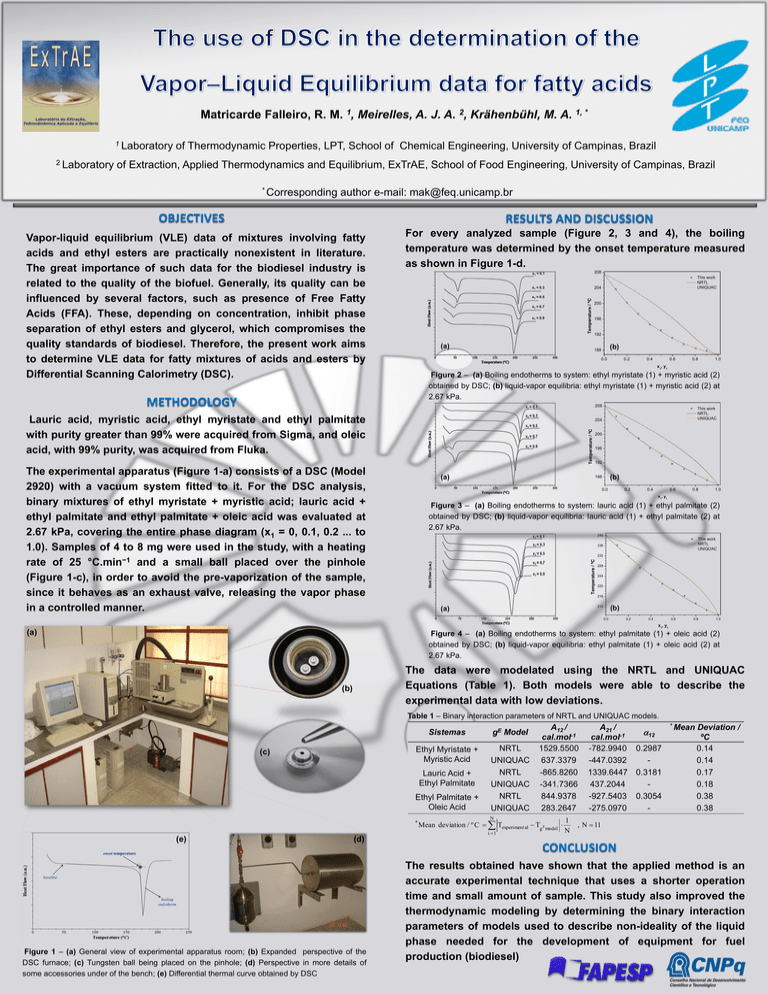

Figure 1-a

advertisement

Matricarde Falleiro, R. M. 1, Meirelles, A. J. A. 2, Krähenbühl, M. A. 1, * Laboratório de EXtração, TeRmodinâmica Aplicada e Equilíbrio 1 Laboratory of Extraction, Applied Thermodynamics and Equilibrium, ExTrAE, School of Food Engineering, University of Campinas, Brazil * Corresponding author e-mail: mak@feq.unicamp.br OBJECTIVES RESULTS AND DISCUSSION Vapor-liquid equilibrium (VLE) data of mixtures involving fatty acids and ethyl esters are practically nonexistent in literature. The great importance of such data for the biodiesel industry is related to the quality of the biofuel. Generally, its quality can be influenced by several factors, such as presence of Free Fatty Acids (FFA). These, depending on concentration, inhibit phase separation of ethyl esters and glycerol, which compromises the quality standards of biodiesel. Therefore, the present work aims to determine VLE data for fatty mixtures of acids and esters by Differential Scanning Calorimetry (DSC). For every analyzed sample (Figure 2, 3 and 4), the boiling temperature was determined by the onset temperature measured as shown in Figure 1-d. 208 x1 ≈ 0.1 x1 ≈ 0.3 This work NRTL UNIQUAC 204 x1 ≈ 0.5 Temperature / ºC 2 Laboratory of Thermodynamic Properties, LPT, School of Chemical Engineering, University of Campinas, Brazil x1 ≈ 0.7 x1 ≈ 0.9 (a) 200 196 192 (b) 188 0.0 0.2 0.4 0.6 0.8 1.0 x1, y1 Figure 2 – (a) Boiling endotherms to system: ethyl myristate (1) + myristic acid (2) obtained by DSC; (b) liquid-vapor equilibria: ethyl myristate (1) + myristic acid (2) at 2.67 kPa. METHODOLOGY 208 Lauric acid, myristic acid, ethyl myristate and ethyl palmitate with purity greater than 99% were acquired from Sigma, and oleic acid, with 99% purity, was acquired from Fluka. This work NRTL UNIQUAC Temperature / ºC 204 The experimental apparatus (Figure 1-a) consists of a DSC (Model 2920) with a vacuum system fitted to it. For the DSC analysis, binary mixtures of ethyl myristate + myristic acid; lauric acid + ethyl palmitate and ethyl palmitate + oleic acid was evaluated at 2.67 kPa, covering the entire phase diagram (x1 = 0, 0.1, 0.2 ... to 1.0). Samples of 4 to 8 mg were used in the study, with a heating rate of 25 °C.min−1 and a small ball placed over the pinhole (Figure 1-c), in order to avoid the pre-vaporization of the sample, since it behaves as an exhaust valve, releasing the vapor phase in a controlled manner. (a) 200 196 192 (b) 188 0.0 0.2 0.4 0.6 0.8 1.0 x1, y1 Figure 3 – (a) Boiling endotherms to system: lauric acid (1) + ethyl palmitate (2) obtained by DSC; (b) liquid-vapor equilibria: lauric acid (1) + ethyl palmitate (2) at 2.67 kPa. 240 This work NRTL UNIQUAC 236 Temperature / ºC 232 228 224 220 216 (b) 212 (a) 0.0 0.2 0.4 0.6 0.8 1.0 x1, y1 (a) Figure 4 – (a) Boiling endotherms to system: ethyl palmitate (1) + oleic acid (2) obtained by DSC; (b) liquid-vapor equilibria: ethyl palmitate (1) + oleic acid (2) at 2.67 kPa. The data were modelated using the NRTL and UNIQUAC Equations (Table 1). Both models were able to describe the experimental data with low deviations. (b) Table 1 – Binary interaction parameters of NRTL and UNIQUAC models. Sistemas Ethyl Myristate + Myristic Acid (c) Lauric Acid + Ethyl Palmitate Ethyl Palmitate + Oleic Acid * gE NRTL UNIQUAC NRTL UNIQUAC NRTL UNIQUAC N Mean deviation / º C Texperiment al Tg E model i 1 (e) (d) onset temperature baseline boiling endotherm Figure 1 – (a) General view of experimental apparatus room; (b) Expanded perspective of the DSC furnace; (c) Tungsten ball being placed on the pinhole; (d) Perspective in more details of some accessories under of the bench; (e) Differential thermal curve obtained by DSC Model A12 / cal.mol-1 1529.5500 637.3379 -865.8260 -341.7366 844.9378 283.2647 1 N A21 / a12 -1 cal.mol -782.9940 0.2987 -447.0392 1339.6447 0.3181 437.2044 -927.5403 0.3054 -275.0970 - * Mean Deviation / ºC 0.14 0.14 0.17 0.18 0.38 0.38 , N 11 CONCLUSION The results obtained have shown that the applied method is an accurate experimental technique that uses a shorter operation time and small amount of sample. This study also improved the thermodynamic modeling by determining the binary interaction parameters of models used to describe non-ideality of the liquid phase needed for the development of equipment for fuel production (biodiesel)