7 Other Projects

advertisement

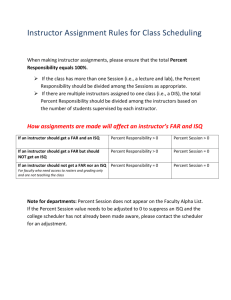

A Quality and Technology Network ISQ Potencial involvement on ESS and the CERN experience Instituto de Soldadura e Qualidade José Oliveira Santos 29 January 2009 1. ISQ 2. Services 3. ESS – Vision 4. Objectives and Motivation 5. Strategy 6. ISQ Participation @ the LHC Project 7. Other Projects 8. The Future Technological Development, Quality and innovation since 1965 1. ISQ – Instituto de Soldadura e Privately owned, non-profit technical and scientific Qualidade organisation Founded in 1965 as Welding Institute Around 1000 co-workers in Portugal and 500 abroad Operating in more than 20 countries Turnover (2009) – ISQ Group: 80 M€ (49% abroad) – ISQ : 62 M€ Accumulated investment in R&D during the last 10 years: 55M€ Headquarter: – Total Area: 40 000 m2 – Covered Area: 15 000 m2 Activity and services in technical areas covering a wide range Industrial Activities 2. ISQ – Services Non Destructive Evaluation Testing Engineering and Performance Thermodynamics, Materials, Mechanical testing, Electromagnetic Compatibility and Finite Element Modeling Production Technologies (welding and brasing) Project Revision and Follow Up Quality Assurance : QA/QC Technical Inspections Health and Safety Maintenance and Structural Integrity Risk Based Inspection : RBI Metrology Training Research and Development ... 3. ESS - Vision ISQ strategy as proved that scientific international cooperation projects are profitable by themselves and provide the levering for technological developments that allow to enter new business markets producing simultaneously a marketing effect capable of generating business on the traditional markets. -Some examples in ISQ recent history include: CERN, ESO, ESA, CNES/ARIANSPACE, FLPP, E- ELT, CHERNOBYL Opportunities: Visibility of ISQ as an R&D partner for industry solutions A market per si. An outstanding and unique opportunity to be present at the development stage of new technological solutions that can place ISQ as a market leader in particular segments of industry. 4. Objectives and Motivation Development of new Non Destructive Evaluation and Production Technologies Solutions ISQ as an international reference, helping on the Internationalization strategy – based on services of high value and technologically unique. Development of Test procedures for the qualification of new Materials and new usage conditions for known materials Placing ISQ as an engineering and testing house for the Automotive, Aero and Nuclear Industries Participation, as third party, in the Quality Assurance / Quality Control of Mechanical and Electrical Components and Assemble Marketing of ISQ image, allowing a different approach on the international market of big Oil and Gas and Public Works Create “critical mass” to enter a new business area in the “nuclear” field Positioning ISQ towards an industry that has never emerged in Portugal, but that can be decisive on the Internationalization strategy in Spain, Brazil, Emirates, China, etc... 5. Strategy Benchmarking the services provided at CERN Benchmarking the CNES/ARIANSPACE QA/QC services provided at Collaboration with the Portuguese Scientific community allowing mutual interest development of competences and positioning in the market To act as service integrator for Portuguese SMEs that can integrate consortium's led by ISQ 6. ISQ Participation @ the LHC Project Introduction Start – September 2001 End - 2007 Inspectors – Integrate a CERN Project Team – Training period in the beginning – Inspections activities coordinated by the Project Team Number of inspectors from 16 till 26 6. ISQ Participation @ the LHC Project General Framework CERN – Assures technical management of Inspectors – Programs Inspector’s activities ISQ – Manages inspector logistics, travels, visas,... – Provides technical support to inspector Working with CERN engineers, ISQ inspector’s functions are: – Follow manufacturing at suppliers or onsite (installation) – Incoming reception of materials at manufacturer – Attend tests according to ITP and at random – Report and follow-up of non conformities – Facilitate interface CERN- Manufacturer – Prepare or supervise the preparation of Travelers at manufacturer – Reporting to CERN Engineers 6. ISQ Participation @ the LHC Project Inspections – personnel and locations 6. ISQ Participation @ the LHC Project Inspections – activities and personnel 6. ISQ Participation @ the LHC Project Contract Management Inspector’s selection and allocation – Competence – Communication skills – Integration: CERN, manufacturer, country – Long term expatriation Multi locations project – Legal issues – Logistics Personal inspector support Overall coordination – Resources – Project development – Contractual reports – Budget control – Inspector’s performance 6. ISQ Participation @ the LHC Project Project Outcome TECHNICAL Management New equipment expertise: – SC Cables – Magnets – Vacuum – Cryogenics, … New experience and knowledge – Large scientifi c projects – High tech project Important reference for similar international projects – SC Cables – Magnets – Vacuum – Cryogenics, – ITER Data Management Process International Environment Financial 7. Other Projects - Engineering 1. Study of new Non Destructive Examination Methodologies on the Poloidal Field Superconductor Jacketing 2. Qualification of a Non Destructive Examination Solution based on Automatic UT (Phased Array) for the Toroidal Field Case Closure Welds – Austenitic materials with high thickness and variable geometry. 3. New methodologies for the control of the brasing between terminations of the superconductors junction (Coper-Coper) 4. Welding technology and Non destructive Examination training for F4E 7.1 Other Projects - Engineering Study of new Non Destructive Examination Methodologies on the Poloidal Field Superconductor Jacketing ITER Magnet System WORK PERFORMED 18 Toroidal Field (TF) coils Central Solenoid (CS) Conventional Radiography with high sensitivity films 6 Poloidal Field (PF) coils Computed Radiography 18 Correction Coils (CC) Computed Tomography H 1 H 2 7.1 Other Projects - Engineering Flaws Notch 1 Notch 2 Notch 3 Notch 4 Notch 5 Hole 1 Hole 2 Conventional Radiography Detected Detecte d Detected Detected Tough Shallow Detecte d Detecte d Computed Radiography Detected Detecte d Detected Detected Shallow Detecte d Detecte d Computed Tomography Detected Detecte d Detected Detected Detected Detecte d Detecte d 7.2 Other Projects - Engineering Qualification of a Non Destructive Examination Solution based on Automatic UT (Phased Array) for the Toroidal Field Case Closure Welds – Austenitic materials with high thickness and variable Receive Transmitter geometry. r Squint angle 2 0<Z<25 0 Vertical scanning 7.2 Other Projects - Engineering Qualification of a Non Destructive Examination Solution based on Automatic UT (Phased Array) for the Toroidal Field Case Closure Welds – Austenitic materials with high thickness and variable geometry. 7.3 Other Projects - Engineering New methodologies for the control of the brasing between terminations of the superconductors junction (Coper-Coper) 7.3 Other Projects - Engineering New methodologies for the control of the brasing between terminations of the superconductors junction (Coper-Coper) 7. Other Projects – Quality Assurance and Inspections QA/QC EFDA As a result of a collaboration with IPFN, ISQ as placed in EFDA a coworker at the position of QA/QC. This co-worker has latter changed from EFDA to F4E where he maintains the same responsibilities, being the the representative of Quality Assurance at Fusion for Energy 7. Other Projects – Quality Assurance and Inspections ESO (European Organisation for Astronomical Research in the Southern Hemisphere) Quality Audit of Cryostat Production (for VLT) : 2007 Scope •Review of ESO relevant documentation •Definition of Audit scope (objectives, responsibilities, processes and documentation to be audited) •Definition of Audit requirements according to the project reference documentation •Audit at suppliers premises •MoM issuing •Final Audit report issuing (audited processes, personnel contacted, documentation reviewed, non-conformities, improvement opportunities) 7. Other Projects – Quality Assurance and Inspections ESO (European Organisation for Astronomical Research in the Southern Hemisphere) Quality and Product Assurance to the E-ELT Project – 2010 -... E-ELT - European Extremely Large Telescope, is a revolutionary new ground-based telescope concept that will be 42 metres in diameter and will be the world's biggest eye on the sky. Scope • Review of ESO PA and QA manuals and procedures in the context of the various ESO contracts with particular attention to issues that may become cost drivers. • Provide a list of suggested modifications to ESO standards • Review of requirements of the technical specifications in the light of the quality and product assurance matters • Review of documentation generated by suppliers • Reporting to E-ELT project office. 7. Other Projects – Quality Assurance and Inspections ESA GSE & Ground Units Certification in the context of ESA Programs Scope Conformity assessment of the ground units that can be used in different countries (amongst others, France for the Guyana Space Centre, the USA for the Kennedy Space Center and the Vandenberg Air Force Base, and Russia for the Plessetsk and Baykonur Cosmodromes), including: Listing the systems prone to risk covered in the study and analysing the regulations of the countries in which these systems may be implemented, Cross-analyses of regulations Definition of certification processes Specifications drawn up for the various types of ground equipment and units used by the ESA. Activities Consulting 7 Other Projects - Testing ESA Consultancy (Technical Assistance) to ESTEC RESIDUAL STRESS MEASUREMENTS IN WELDED Ti ALLOY PLATES SUPPORT TO THE METROLOGY LABORATORY ON THE ACCREDITATION IN ROUNDNESS MEASUREMENTS - Support to ESTEC Metrology Laboratory on its accreditation with ISO 17025 in roundness measurements. FATIGUE TEST OF THREADED A2-70 SIZE M5 FASTENERS - To present a test program to establish the fatigue strength of “cheese head” M5 size, fasteners made of A2-70 austenitic stainless steel, according to DIN912. Scope Laboratory measurements and measurement tools development; Consultancy on metrological technology, procurement, equipments maintenance, installation support and procedures; Procedures development Training in specific measurement techniques; Feasibility Assessment; 7 Other Projects - Testing Alcatel-Alenia Space: Re-entry simulation test on metallic TPS To perform several cycles simulating the re-flight of a reasonable re-entry system. The tests will be performed in test articles with a maximum temperature on the test article of 900ºC, with pressure variable from 5hPa up to ambient pressure. Data will be gathered from 19 thermocouples, 6 displacement sensors and 1 pressure sensor. 7 Other Projects - Testing SNECMA PROPOLSION SOLIDE – Windward and Nose C/SiC Assembly Tests IXV program is an ESA program, which aim is to study the atmospheric re-entry with a vehicle named Intermediate eXperimental Vehicle. Snecma Propulsion Solide is responsible for the Windward assembly and the Nose assembly Scope Mechanic and thermal characterisation of the attachment system: Mechanical test on the MACOR washers Mechanical characterization of the standoff Characterization of the screw with a constant temperature Thermal characterization Insulation Tests Elementary insulation characterization Insulation interface thermal characterization Engineering test thermomechanical characterizations Insulation stack-up thermal characterization 7 Other Projects - Testing Thales Alenia Space: FLPP- Future Launchers Preparatory Program Period 2 Step 1 Cryogenic Upper Stages Technology - CUST 1.1 – In Progress Scope • Test Campaign Definition and Planing • Test Procedures and Facility Set-up / Test Execution • Raw Materials and Technology Process Samples • Mechanical tests • Thermal tests • Modal Survey on Full Scale Panel • Sinusoidal and Random Tests on Full Scale Panel 7 Other Projects - Testing AIRBUS EMOC Coupons Tests – in Progress As part of the Multi Disciplinary Optimised Wing Project WP3.2.1.4, this test campaign is being carried out to understand the effect of absorbed moisture on composite materials (EMOC). These tests will provide preliminary information on the effect of absorbed moisture temperature on strength. Specimens will undergo environmental conditioning prior to testing and be subject to strict environment control. The tests themselves will also be carried out across a range of temperatures. Scope • In plane shear tests • 90º tension tests • 0º compression tests • 90º compression tests • Open hole compression (OHC) • Filled hole compression (FHC) 7 Other Projects - Nuclear Welding Inspection during the fabrication of piping for the French Nuclear reactor RES – Project launched by the French partner APAVE Welding Inspection during the fabrication of piping for the French Nuclear reactor Flamanville 3 – AREVA EPR - Project launched by the French partner APAVE Non Destructive Examination, performed by ISQ Spain, for Tecnatom, during the periodic shut-downs of Spanish Nuclear Facilities in Valencia 8. The Future ISQ will maintain its strategy establishing it self as a partner for research and development during the engineering phase. Following the first step, ISQ will approach the industry main contractors in the perspective of the technology transfer Collaboration with the owner of the installation shall try to encompass services as technical inspections (on mechanical construction and electrical facilities) and 3rd party Quality Assurance Act as a National SME integrator in multi-disciplinary projects that involve competences not available in-house. Instituto de Soldadura e Qualidade A Quality and Technology Network ISQ 2010