Experiment 5 Pipe Flow-Major and Minor losses

advertisement

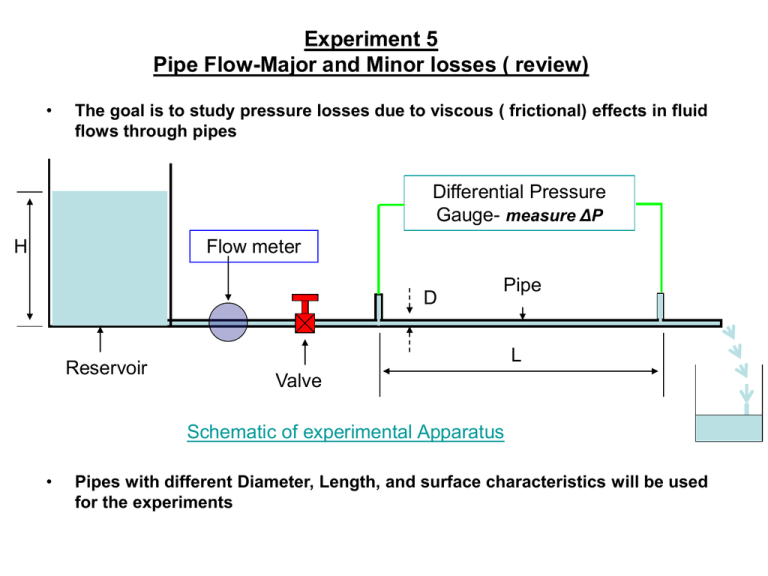

Experiment 5 Pipe Flow-Major and Minor losses ( review) • The goal is to study pressure losses due to viscous ( frictional) effects in fluid flows through pipes Differential Pressure Gauge- measure ΔP H Flow meter D Reservoir Pipe L Valve Schematic of experimental Apparatus • Pipes with different Diameter, Length, and surface characteristics will be used for the experiments Major and Minor losses Total Head Loss( hLT) = Major Loss (hL)+ Minor Loss (hLM) Due to wall friction LV2 Darcy' s Equation hl f D 2g In this experiment you will find friction factor for various pipes Due to sudden expansion, contraction, fittings etc hlm V2 K 2g K is loss coefficient must be determined for each situation For Short pipes with multiple fittings, the minor losses are no longer “minor”!! Major loss Differential Pressure Gaugemeasure ΔP L ρ V ε Pipe D • μ Physical problem is to relate pressure drop to fluid parameters and pipe geometry P( ,V , L, , D, ) Using dimensional analysis we can show that VD L , , D D 1 2 V 2 P Friction factor P 1 2 V 2 L VD , D D L VD 1 P , V 2 D D 2 VD define friction factor f , D LV2 hL f L 1 2 ie P f V D 2g D 2 D 1 L1 2 f PL or PL f V D2 L 1 2 V 2 PL LV 2 hL f g D 2g Friction Factor VD f , D • f Re, D For Laminar flow ( Re<2300) inside a horizontal pipe, friction factor is independent of the surface roughness. ie f Re only. Theoretically we can derive the functional relationship as 64 f Re • • For Laminar flow For Turbulent flow ( Re>4000) it is not possible to derive analytical expressions. Empirical expressions relating friction factor, Reynolds number and relative roughness are available in literature Friction factor correlations / D 2.51 1 Colebrook Equation 2.0 log f 3.7 Re f f is not related explicitly Re and relative roughness in this equation. The following equation can be used instead f 1.325 5.74 0.9 ln 3.7 D Re 2 for 106 D 10 2 and 5000 Re 108 Moody’s chart for friction factor /D f Laminar Transition f=64/Re ReD Increases Minor Losses Valves Bends T joints hlm Expansions Contractions V2 K 2g • Flow separation and associated viscous effects will tend to decrease the flow energy and hence the losses • The phenomenon is fairly complicated. Loss coefficient ‘K’ will take care of this complicities Experiment 5 - New Experimental Set up H Reservoir Digital Manometer To measure ΔP Experiment 5 - Experimental Steps & Details Overall Measurements H 1. Measure the Reservoir Height, H 2. Measure the Distances L1, L2, etc. 3. Measure the distances Δx1, Δx2, etc. Measure the pipe diameters Reservoir L1 For EACH PIPE Follow Steps below L2 L3 L4 Δx2 • Δx1 Set the reservoir height, H, to the maximum level, approx. close to the ‘spill-over’ partition height. Record the level. Δx2 • Adjust the flow rate to a relatively high value, wait for steady flow to be established. Δx3 1. Measure the flow rate. 2. Measure the pressure drop, ΔP, for this flow rate. 3. Reduce the flow rate, by using the valves, repeat steps 1 & 2. 4. Reduce the reservoir height and repeat steps 1-3. 5. Repeat all steps until 3 reservoir heights have been measured Hence for each pipe, you will measure ΔP, for six flow rates (3 H x 2 valve openings)