投影片 1 - stust.edu.tw

advertisement

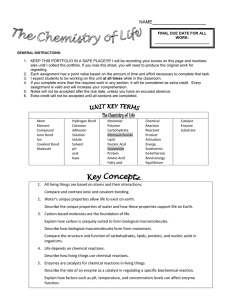

Professor: Cheng-Ho Chen Graduate: Po-Huei Tseng Date: 101.12.19 Outline Introduction Experiment Results and Discussion Conclusions References 2 Introduction(1) Ionomers: macromolecules composed of a small but significant proportion of constitutional units (less than 10%) containing an ionic and/or ionizable group. The ionic groups cause a micro-phase separation of the ionic moieties (ionic aggregation) within the non-ionic matrix and act as physical crosslinks. Ionomers of low glass-transition non-crystalline polymers 3 can be used as ionic thermoplastic elastomers (TPEs) if the ionic aggregates are sufficiently weakened at the processing temperatures. Introduction(2) TPEs: melt-processable polymers composed of a continuous elastomeric phase. Both the precursor elPP-g-MA and the ionomers were synthesized by melt-processing. The neutralization reaction was monitored by infrared spectroscopy and a method is proposed to determine the effective neutralization degree (ND). Various forms of sodium hydroxide and sodium acetate were used to compare their efficiency of elPP-g-MA neutralization. 4 Outline Introduction Experiment Results and Discussion Conclusions References 5 Materials Materials Isotactic homopolymer PP powder 2,5-bis(tert-butyl-peroxy)2,5dimethylhexane[DHBP] Purchase Purity Moplen HF500N Basell 50 wt% blend with Si Arkema Maleic anhydride(MA) 99% Acros N-bromosuccinimide(NBS) 99% Acros Sodium Acetate Trihydrate (NaAcTH) 99% Aldrich NaOH(pellets) 99+% Aldrich NaOH(powder) 97% Aldrich Sodium Acetate Anhydrous(SAA) 99% Aldrich Tolune(analytical grade) Luperox 101XLS50 Company Fisher 6 Equipments Equipments DSC SEC FTIR TGA 7 Model DSC 821e GPCV 2000 Nexus 670 TGA/SDTA 851e Manufacturer Mettler Toledo Waters Alliance Nicolet Mettler Toledo Synthesis 1 elPP-g-MA 8 Synthesis 2 Ionomer 9 Characterization Quantification of the grafted species Differential scanning calorimetry (DSC) Size exclusion chromatography(SEC) Fourier transform infrared (FTIR) spectroscopy Thermogravimetric analysis (TGA) Rheological properties 10 Quantification of the grafted species 11 DSC Crystallinity and Tg of elPP-g-MA and ionomers: evaluated from a second heating ramp from -50 to 220℃ at 10℃/min. The device was calibrated with indium and zinc. 12 SEC The mobile phase: 1,2,4-trichlorobenzene(TCB) The concentration of the sample: 2 mg/mL in TCB dissolution: shaking at 160℃ for 1 h The injection volume: 215 μL 13 Temperature: held constant at 145℃ FTIR the peak height of the 973 cm-1 absorption band to an absorbance of 1 The frequency range of absorption bands area: 1.carbonyl of the anhydride (1750-1830 cm-1) 2.carbonyl of the carboxylic acid (1650-1750 cm-1) 14 TGA heating rate: 10℃/min under air atmosphere(100 mL/min) temperature: 25-600℃ 15 Rheological properties Equipment: Rubber Process Analyser RPA 2000, Alpha Technologies Frequency sweep tests: performed at 120℃ at a strain rate of 10% over an angular frequency ranging from 300 to 1 rad/s 16 Outline Introduction Experiment Results and Discussion Conclusions References 17 elPP-g-MA Characterization The degradation of the molar mass is caused by a side reaction, β-scission, occurring during the functionalization. The crystallinity of elPP-g-MA is strongly reduced with respect to the starting PP, due to the epimerization reaction occurring in the presence of peroxide and NBS. 18 Ionomer ND determination(1) 19 Ionomer ND determination(2) 1790 1715 1863 20 1570 Ionomer ND determination(3) If the ND were calculated on the basis of the decrease of the anhydride band at 1790 cm-1 from elPP-g-MA (AanhelPP-g-MA) to ionomer (Aanhionomer), it would be overestimated due to the carboxylic acid functions contribution. ND 21 Aanhionomer AanhelPPg MA 100 Ionomer ND determination(4) 22 Influence of the nature of the base on ND NaOH 2.5 M > NaOH sol. ≒ NaAc*3H2O sol. > NaAc 2.5 M > NaAc. anh. sol. 23 Ionomer Characterization DSC TGA Rheology 24 DSC elPP-g-MA: Tg is around -4.2℃ and a weak broad melting peak. Ionomers: only Tg Tg for all the ionomers are similar to the one of elPP-g-MA. 25 TGA 26 Rheology 27 Conclusions The choice of the base has a strong influence on the neutralization degree. As the neutralization yield never reaches 100%, the excess of the added sodium hydroxide may lead to corrosion. Sodium acetate is preferred over sodium hydroxide. The thermal stability in air atmosphere, shear storage modulus and complex viscosity in the flow region were largely increased as a function of the neutralization degree. 28 References [1] Hess M, Jones RG, Kahovec J, Kitayama T, Kratochvíl P, Kubisa P, et al. Terminology of polymers containing ionizable or ionic groups and of polymers containing ions (IUPAC recommendations 2006). Pure and Applied Chemistry 2006; 78(11); 2067-74. [2] Holliday L, editor. Ionic polymers. London: Applied Science Publishers; 1975. [3] Eisenberg A, editor. Ions in polymers. Washington, DC: American Chemical Society; 1980. [4] Utracki L, Weiss R, editors. Multiphase polymers: blends and ionomers, vol. 1. Washington, DC: American Chemical Society; 1989. [5] Schlick S, editor. Ionomers: characterisation, theory and applications. Boca Raton, Florida: CRC Press; 1996. [6] Tant MR, Mauritz K, Wilkes G, editors. Ionomers: synthesis, structure, properties and applications. London: Springer; 1997. [7] Eisenberg A, Kim J-S, editors. Introduction to ionomers. New-York: Wileyinterscience; 1998. 29 [8] Bagrodia S, Wilkes GL, Kennedy JP. New polyisobutylene-based model elastomeric ionomers: rheological behavior. Polymer Engineering and Science 1986; 26(10): 662-72. [9] van der Mee MAJ, Abee RMA, Portale G, Goossens JGP, van Duin M. Synthesis, structure, and properties of ionic thermoplastic elastomers based on maleated ethylene/propylene copolymers. Macromolecules 2008;41(14): 5493-501. [10] Work WJ, Horie K, Hess M, Stepto RFT. Definition of terms related to polymer blends, composites, and multiphase polymeric materials (IUPAC recommendations 2004). Pure and Applied Chemistry 2004;76(11): 1985-2007. [11] Kutsumizu S, Tagawa H, Muroga Y, Yano S. Small-angle X-ray scattering investigation of noncrystalline poly(ethylene-co-methacrylic acid) ionomers. Macromolecules 2000; 33(10): 3818-27. [12] Kutsumizu S, Tadano K, Matsuda Y, Goto M, Tachino H, Hara H, et al. Investigation of microphase separation and thermal properties of noncrystalline ethylene ionomers. 2. IR, DSC, and dielectric characterization. Macromolecules 2000 ;33(24): 9044-53. [13] molecular weight maleated ethylene-propylene copolymers (man-g-epm) as investigated by small-angle x-ray scattering. Macromolecules 2002; 35(1): 208-16. [14] Wouters MEL, Litvinov VM, Binsbergen FL, Goossens JGP, van Duin M, Dikland HG. Morphology of ethylene-propylene copolymer based ionomers as studied by solid state nmr and small angle x-ray scattering in relation to some mechanical properties. Macromolecules 2003; 36(4): 1147-56. 30 [15] Grady BP, Goossens JGP, Wouters MEL. Morphology of zinc-neutralized maleated ethylene-propylene copolymer ionomers: structure of ionic aggregates as studied by x-ray absorption spectroscopy. Macromolecules 2004; 37(23): 8585-91. [16] Sun C, van der Mee M, Goossens J, van Duin M. Thermoreversible cross-linking of maleated ethylene/propylene copolymers using hydrogen-bonding and ionic interactions. Macromolecules 2006; 39: 3441-9. [17] Henry G, Drooghaag X, Rousseaux D, Sclavons M, Devaux J, Marchand-Brynaert J et al., A practical way of grafting maleic anhydride onto polypropylene providing high anhydride contents without sacrificing excessive molar mass. Journal of Applied Polymer Sciences; Part A; Polymer Chemistry 2008; 46(9); 2936-47. [18] Sclavons M, Franquinet P, Carlier V, Verfaillie G, Fallais I, Legras R, et al. Quantification of the maleic anhydride grafted onto polypropylene by chemical and viscosimetric titrations, and FTIR spectroscopy. Polymer 2000; 41: 1989-99. [19] Burfield D, Loi P. The use of infrared spectroscopy for determination of polypropylene stereoregularity. Journal of Applied Polymer Science 1988;36(2): 279-93. 31 32