Slide 1 - UniMAP Portal

advertisement

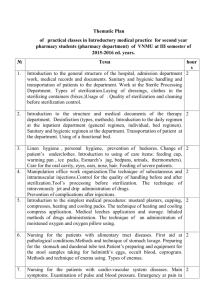

ERT 416/3 CHAPTER 7: UPSTREAM PROCESSING IN BIOPROCESS PLANT MISS. RAHIMAH BINTI OTHMAN (Email: rahimah@unimap.edu.my) COURSE OUTCOME 1 CO1) CHAPTER 7 : Upstream Processing In Bioprocess Plant. CLASSIFY the elements of bioprocesses; LIST typical unit operations in bioprocess like sterilization, fermentation, enzymatic reactions, extraction and filtration or crystallization and DEFINE the unit procedure involved for the process design. UNDERSTAND and LIST typical upstream steps like preparation of medium, the sterilization of the raw materials and the inoculums preparation. DECIDE and DESIGN suitable upstream processing units for the design process based on stoichiometry, thermodynamics, separation and reaction engineering principles. CHAPTER 8 : Bioreaction Design In Bioprocess Plant. CHAPTER 9 : Downstream Processing In Bioprocess Plant. CHAPTER 10: Integrated Bioseparation Scheme for Product Isolation, Purification and Formulation Units For Bioprocess. OUTLINES 1. LIST of typical unit operations in bioprocess plant system. 2. DEFINITION of the unit procedure involved for the process design. 3. UNDERSTANDING the typical upstream steps like preparation of medium, the sterilization of the raw materials and the inoculums preparation. 4. SELECTION and DESIGN PROCEDURE on the suitable upstream processing units for the design process based on stoichiometry, thermodynamics, separation and reaction engineering principles. GENERALIZED VIEW OF BIOPROCESS RAW MATERIALS UPSTREAM PROCESSES Inoculum Preparation Equipment Sterilization Media Formulation and Sterilization BIOREACTOR - FERMENTER Reaction Kinetics and Bioactivity Transport Phenomena and Fluid Properties Instrumentation and Control DOWNSTREAM PROCESSES Separation Recovery and Purification Waste Recovery, Reuse and Treatment THE BOTTOM LINE REGULATION ECONOMICS HEALTH AND SAFETY LIST OF TYPICAL UNIT OPERATIONS IN BIOPROCESS PLANT SYSTEM 1. Sterilization 2. Fermentation 3. Enzymatic reactions 4. Extraction and filtration 5. Crystallization DEFINITION OF THE UNIT PROCEDURES FOR THE PROCESS DESIGN 1. Sterilization Definition: Sterilization (or sterilisation) is a term referring to any process that eliminates (removes) or kills all forms of life, including transmissible agents (such as fungi, bacteria, viruses, spore forms, etc.) present on a surface, contained in a fluid, in medication, or in a compound such as biological culture media. Sterilization can be achieved by applying the proper combinations of heat, chemicals, irradiation, high pressure, and filtration. AUTOCLAVE DEFINITION OF THE UNIT PROCEDURES FOR THE PROCESS DESIGN 1. Sterilization (i) Sterilization of Liquid Media a) Batch Sterilization of Liquid Media b) Continuous Sterilization of Liquid Media c) Kinetics of Thermal Death of Microorganisms d) Examples of Design for Continuous Liquid Medium Sterilization in a Tubular Sterilizer (ii) Air Sterilization by Fibrous Bed Filters Mechanisms of Air Filtration Design of Fibrous Packed Beds Example of Design of Fibrous Packed Bed for Air Sterilization Schematic Diagram of Continous Sterilizer System. Overview of Sterilizer Phases Fibrous Packed Bed for Air Sterilization 1. STERILIZATION OF LIQUID MEDIA The liquid media which contains all essential nutrients for cell growth is: First heat sterilized with steam, then; Cooled down before introduction into the bioreactor vessel Two types of sterilization: Batch sterilization (see Fig. 5.1, and Table 5.1 for corresponding temperature profile) Continuous sterilization (see Fig. 5.2a, 5.2b) (i-a) Batch Sterilization of Liquid Media FIG. 5.1 Types of equipment for batch sterilization of media. [Adopted from S. Aiba, A.E. Humphrey and N.F. Millis. “Media Sterilization”. In Biochemical Engineering, 2nd Ed., Academic Press, Inc., New York (1973) 254]. TABLE 5.1. Temperature-Time Profile in Batch Sterilization. [Adopted from S. Aiba, A.E. Humphrey and N.F. Millis. “Media Sterilization”. In Biochemical Engineering, 2nd Ed., Academic Press, Inc., New York (1973) 254]. (i-b) Continuous Sterilization of Liquid Media Two types of continuous sterilization: Direct steam injection sterilizer (see Fig. 5.2a) Plate heat exchanger sterilizer (see Fig. 5.2b) FIG. 5.2a Direct steam injection type of continuous sterilization of liquid media. [Adopted from S. Aiba, A.E. Humphrey and N.F. Millis. “Media Sterilization”. In Biochemical Engineering, 2nd Ed., Academic Press, Inc., New York (1973) 257]. FIG. 5.2b Plate heat exchanger type of continuous sterilization of liquid media. [Adopted from S. Aiba, A.E. Humphrey and N.F. Millis. “Media Sterilization”. In Biochemical Engineering, 2nd Ed., Academic Press, Inc., New York (1973) 257]. Fig. 5.3a and 5.3b show the temperature-time profiles for the two types of continuous sterilization. FIG. 5.3a Sterilization temperature vs. time profile for direct steam injection continuous sterilizer. [Adopted from S. Aiba, A.E. Humphrey and N.F. Millis. “Media Sterilization”. In Biochemical Engineering, 2nd Ed., Academic Press, Inc., New York (1973) 258]. FIG. 5.3b Sterilization temperature vs. time profile for plate heat exchanger sterilizer. [Adopted from S. Aiba, A.E. Humphrey and N.F. Millis. “Media Sterilization”. In Biochemical Engineering, 2nd Ed., Academic Press, Inc., New York (1973) 257]. (i-c) Kinetics of Thermal Death of Microorganisms Heat is used to kill: Contaminant microorganisms Spores - present in a liquid nutrient medium. The destruction of microorganisms by heat means: Loss of Viability of these microorganisms and spores. The thermal death of microorganisms follow first order kinetics given by Eq. 5.1. dN/dt = -kN……………………...(5.1) Where: N = Number of viable microorganisms t = Sterilization time, min k = Thermal death rate constant, min-1 If at time t0 = 0, N = N0, then integration of Eq.5.1 results in Eq. 5.2. N = N0 e-kt ………………………(5.2) Also: ln(N/N0) = -kt ………………….(5.3) The term decimal reduction time, D, is used to characterize the death rate constant. D is defined as the sterilization time required to reduce the original number of viable cells by one tenth. N/N0 = 1/10 = e-kD ln(0.10) = -Kd D = 2.303/k……………………………(5.4) Fig. 4.4 and 4.5 shows typical data of N/N0 vs. sterilization time for spores of Bacillus stearothermophillus, one of the hardest spores to kill, and vegetative cells of E. coli FIG. 4.4 Typical thermal death rate data for spores of Bacillus stearothermophilus Fs 7954 in distilled water where N = number of viable spores at any time, N0 = original number of viable spores. [Adopted from S. Aiba, A.E. Humphrey and N.F. Millis. “Media Sterilization”. In Biochemical Engineering, 2nd Ed., Academic Press, Inc., New York (1973) 241]. FIG. 4.5 Typical death rate data for E. coli in buffer, where N = number of viable spores at any time, N0 = original number of viable spores. [Adopted from S. Aiba, A.E. Humphrey and N.F. Millis. “Media Sterilization”. In Biochemical Engineering, 2nd Ed., Academic Press, Inc., New York (1973) 241]. The thermal death rate constant k is given by Eq. 5.5 and follows the typical Arrhenius equation. K = A e-E/RT………………………(5.5) Where: A = empirical constant E = Activation energy for thermal death of microorganism T = Absolute temperature, oK R = Gas constant = 1.98 cal/g mole oK Fig. 4.6 and 4.7 shows the Arrhenius plots of k for spores of B. stearothermophilus, and vegetative cells of E. coli, respectively. FIG. 4.6 Correlation of isothermal death rate data for spores of Bacillus stearothermophilus Fs 7954, where k = reaction rate constant and T = absolute temperature. Value of E (activation energy) = 68.7 kcal/ g mole. [Adopted from S. Aiba, A.E. Humphrey and N.F. Millis. “Media Sterilization”. In Biochemical Engineering, 2nd Ed., Academic Press, Inc., New York (1973) 242]. FIG. 4.7 Correlation of isothermal death rate data with temperature for E. coli, where k = reaction rate constant and T = absolute temperature. Value of E (activation energy) = 127 kcal/g mole. [Adopted from S. Aiba, A.E. Humphrey and N.F. Millis. “Media Sterilization”. In Biochemical Engineering, 2nd Ed., Academic Press, Inc., New York (1973) 243]. For spores of B. stearothermophilus, the following kinetic parameters apply: A = 7.94 x 1038 min-1 E = 68.7 x 103 cal/g mole The higher the value of E, the more difficult it is to kill by thermal denaturation a microorganism or spore. The value of activation energy, E, due to thermal denaturation (death) for vegetative microbial cells and spores is in the range of E = 50 to 100 kcal/g mole. For the thermal denaturation of enzymes, vitamins, and other fragile nutrients, the activation energy, E, is in the range of E = 2 to 20 kcal/ g mole. For a given liquid medium containing both, it is easier (faster) to denature thermally, enzymes and vitamins and other nutrients, and more difficult (slower) to denature (kill) vegetative cells. In order to find the value of k for any system (spores and vegetative cells, nutrients) it is important to know both A and E in the Arrhenius Eq. 5.5. Sterilization at relatively high temperatures with short sterilization times is highly desirable because it favours the fast killing of vegetative cells and spores with minimal denaturation of nutrients present in the liquid medium. BATCH STERILIZATION OF LIQUID MEDIA During batch sterilization: Both temperature and time change Also k changes with time, since k = f (T) Table 4.1 shows the sterilization temperature as a; function of time for batch sterilization using different types of heat transfer and cooling. dN/dt = -kN = -Ae-E/RT N…(5.6) Integrating Eq. 5.6 from t0 = 0, N = N0 to any time t = t and N = N, we get Eq. (5.7). ln(N0/N) = 0t kdt = A 0t e-E/RTdt ….....(5.7) We define: = ln (N0/N)………………………….(5.8) In sterilization design: Is used as a criterion of design. Specifies the level of sterilization required for a liquid nutrient medium. During batch sterilization, there are three periods of sterilization: Heating of the liquid medium period Holding at constant temperature period Cooling period During each period, a separate value of Total = ln(N0/N) = heating + holding + heating = ln(N0/N1) = 0t1 kdt holding = ln(N1/N2) = t1t2 kdt cooling is calculated: cooling………(5.9) = ln(N2/N) = t2t3 kdt Where: N = No. of contaminants after sterilization N0 = No. of contaminants before sterilization N1 = No. of contaminants after heating period t1 N2 = No. of contaminants after holding period t2 t1, t2, t3 = Sterilization times during, heating, holding and cooling. Total batch sterilization time, t, is given by Eq. 5.10. t = t1 + t2 + t3 .………………..(5.10) EXAMPLE OF BATCH STERILIZATION Calculate the total degree of batch sterilization, total, for a liquid medium inside a bioreactor vessel, which reaches maximum temperature 120 oC, and then cooled off. Assume that the liquid medium contains spores of B. stearothermophilus, and the initial total number is N0 = 6 x 1012 spores. The temperature vs. time profile during batch sterilization is given below. t (min) T1 (oC) 0 30 10 50 30 90 36 100 43 110 50 120 55 120 58 110 63 100 70 90 102 60 120 44 140 30 For spores of B. stearothermophilus: k = 7.94 x 1038 exp[(-68.8 x 103)/RT] min-1 R = 1.98 cal/g mole oK FIG. 4.8 Batch sterilization: k and T vs. t ; example calculation. Area under the curve k vs. t is total degree of sterilization, total. [Adopted from S. Aiba, A.E. Humphrey and N.F. Millis. “Media Sterilization”. In Biochemical Engineering, 2nd Ed., Academic Press, Inc., New York (1973) 256]. Fig. 4.8 shows the temperature-time profile and the value of k as a function of T [i.e. k = f (T)] as given in the previous slide. Examining Fig. 4.8, it is also evident that the values of k are a function of t [i.e. k = f (t)], ranging between 0 to 34 min, and between 64 to 140 min. Therefore, the area under the curve k (min-1) vs. t (min) is the graphical integration, which gives: 140 kdt = 33.8 = ln(N /N) = total 0 0 N = N0/exp(33.8) = 6x1012/4.77698x104 = 1.256x10-2 CONTINUOUS STERILIZATION OF LIQUID MEDIA Fig. 4.2a and 4.2b show the two most common types of continuous sterilizers used with steam to carry out the sterilization of liquid fermentation media. In both systems, the liquid medium is heated rapidly the desired high temperature either by direct steam injection or by plate heat exchangers and then it goes through a holding section, which is a tube of given diameter and length to give the desired residence (holding) sterilization time: The holding tubular section is well insulated and it is held at the same sterilization temperature along its length. Fig. 4.3a and 4.3b give approximate temperature-time profiles for the steam injection and plate heat exchanger types respectively. NOTE: The direct steam injection gives much faster rise in temperature but, the original liquid medium is being diluted by the amount of the steam condensate during the injection of the steam. Therefore, an enthalpy and mass balance is required at the steam injection nozzle. The problem: design and size both the diameter and length of the tubular holding section which is held at a given temperature assuming a desired degree of sterilization, using the thermal rate constant and its Arrhenius relationship for spores of B. stearothermophilus, which is one of the hardest spores to kill by steam sterilization. NOTE: In both the injection type and plate exchanger type of continuous sterilizers, it is required to design (size-up) the length and diameter of the tubular holding section. 3. Enzymatic Reactions 3. Enzymatic Reactions 1. Enzymes are proteins that catalyze (i.e., increase the rates of) chemical reactions. 2. In enzymatic reactions, the molecules at the beginning of the process are called substrates, and the enzyme converts them into different molecules, called the products. 3. Almost all processes in a biological cell need enzymes to occur at significant rates. 4. Since enzymes are selective for their substrates and speed up only a few reactions from among many possibilities, the set of enzymes made in a cell determines which metabolic pathways occur in that cell. The Enzymatic Reactions Flow Diagram The energies of the stages of a chemical reaction. Substrates need a lot of energy to reach a transition state, which then decays into products. The enzyme stabilizes the transition state, reducing the energy needed to form products. Industrial Application Application Food processing Amylases catalyze the release of simple sugars from starch Enzymes used Amylases from fungi and plants. Proteases Enzymes from barley are released during the mashing stage of beer production. Industrially produced barley enzymes Brewing industry Germinating barley used for malt. Amylase, glucanases, proteases Betaglucanases and arabinoxylanases Amyloglucosidase and pullulanases Proteases Uses Production of sugars from starch, such as in making high-fructose corn syrup.In baking, catalyze breakdown of starch in the flour to sugar. Yeast fermentation of sugar produces the carbon dioxide that raises the dough. Biscuit manufacturers use them to lower the protein level of flour. They degrade starch and proteins to produce simple sugar, amino acids and peptides that are used by yeast for fermentation. Widely used in the brewing process to substitute for the natural enzymes found in barley. Split polysaccharides and proteins in the malt. Improve the wort and beer filtration characteristics. Low-calorie beer and adjustment of fermentability. Remove cloudiness produced during storage of beers. Industrial Application Application Dairy industry Roquefort cheese Enzymes used Uses Rennin, derived from the stomachs of young ruminant animals (like calves and lambs). Manufacture of cheese, used to hydrolyze protein. Microbially produced enzyme Now finding increasing use in the dairy industry. Lipases Is implemented during the production of Roquefort cheese to enhance the ripening of the blue-mould cheese. Lactases Break down lactose to glucose and galactose. Amylases, amyloglucosideases and glucoamylases Glucose isomerase Glucose Starch industry Fructose Converts glucose into fructose in production of high fructose syrups from starchy materials. These syrups have enhanced sweetening properties and lower calorific values than sucrose for the same level of sweetness. Industrial Application Application Enzymes used Amylases, Xylanases, Cellulases and ligninases Degrade starch to lower viscosity, aiding sizing and coating paper. Xylanases reduce bleach required for decolorising; cellulases smooth fibers, enhance water drainage, and promote ink removal; lipases reduce pitch and lignin-degrading enzymes remove lignin to soften paper. Cellulases Used to break down cellulose into sugars that can be fermented (see cellulosic ethanol). Ligninases Use of lignin waste Restriction enzymes, DNA ligase and polymerases Used to manipulate DNA in genetic engineering, important in pharmacology, agriculture and medicine. Essential for restriction digestion and the polymerase chain reaction. Molecular biology is also important in forensic science. Paper industry A paper mill in South Carolina. Bio fuel industry Cellulose in 3D Molecular biology Part of the DNA double helix. Uses Thank you Prepared by, MISS RAHIMAH OTHMAN