Corrosion Intercept ™Presentation

advertisement

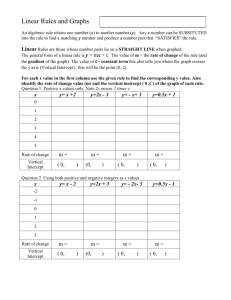

CORROSION INTERCEPT® Technology Protection for Steel and Iron FPM Inc Simply Better Protection Member of the Intercept Techology Group Copyright2004, Intercept Technology Group Corrosion Intercept Or Protecting your Investment and Your Product Copyright2004, Intercept Technology Group CT Scanner Quick Pack Shroud and Base Sheet 5 Minute Pack Out Approved for Export Shipping Shrink Wrapping and Custom Covers Copyright2004, Intercept Technology Group Types of corrosive gases • Nitrous Oxides (NOx) • Ozone (O3) - reactive oxygen • Hydrogen Sulfide (H2S) and Sulfur Dioxides (SO2) • Carbonyl Sulfide (COS) • Hydrogen Chloride (HCl) • Corrosive gases from wood offgassing Copyright2004, Intercept Technology Group CORROSION INTERCEPT® CI is being used by a number of renowned companies. Intercept Advantages: • Environmentally-friendly (no migration of particles and elements) when used as directed • High effectiveness ( from –35°C to +80°C) • Long durability ( > 10 Years per mil of resin under average atmospheric conditions) • Protects all Ferrous- and Non-Ferrous metals, electronics, optics and plastics from atmospheric corrosion • Universally usable • Cost-effective Copyright2004, Intercept Technology Group Function CI Products consist of special high surface area copper particles which are reacted into the polymer-matrix to create a new class of product with several protective functions: • Neutralization of corrosive gases present in the bag and migrating gases • Protection as an “Anode“ for electro-chemical processes • Natural function against Bio-Corrosion (copper is a passive mildewcide) Copyright2004, Intercept Technology Group How Intercept Works Copyright2004, Intercept Technology Group US Army TACOM (Tank, Automotive & Munitions Command) EVALUATION OF INTERCEPT BARRIER MATERIAL FOR MILITARY PACKAGING SALT-FOG Test Data Comparison <<<<< Days of protection against corrosion >>>>>>> Metal coupon Intercept Poly VCI Poly MIL-PRF-131 Foil / Poly 4-mil 4-mil Steel 102 28 62 Aluminum 130 59 91 Brass 130 28 91 97 59 77 Zinc Copyright2004, Intercept Technology Group 5-mil Workers‘ Safety & Environment - Intercept is not a VCI - There is no outgassing and there are no VOC issues related to Intercept - There are no restrictions for Intercept in regards to: - German Gov’t TRGS 615 – Intercept is compliant - RoHS - Intercept meets RoHS initiative in Europe - Fully reusable and recyclable as colored PE in Europe CORROSION INTERCEPT® was tested by NASA for contamination – certified for space-flight conditions Copyright2004, Intercept Technology Group CI Benefits • Eliminates the need for oils, greases and solvents • Saves Labor dollars and time • Contains no volatile compounds • Provides long-term protection • Ease of application • Inexpensive compared to other products when considering all packaging costs Copyright2004, Intercept Technology Group Intercept Stretch Wrap Benefits: • Corrosion Intercept may be wrapped over irregular shapes – flip the film over to get the film to tack closed • Corrosion Intercept acts as a moisture vapor barrierpreventing moisture from entering the package • Corrosion Intercept film may be adequate to hold the object on a pallet without additional packaging. Copyright2004, Intercept Technology Group Corrosion Intercept film (far right) placed in an atmosphere containing chlorine performs significantly better than other packaging films (foil, blue poly, volatile corrosion inhibitor). Copyright2004, Intercept Technology Group In addition to acting as a barrier to external atmospheric gases the Corrosion Intercept film scavenges any corrosive gases that might be enclosed in the air space inside the package. Corrosion Intercept also acts as a sacrificial anode and prevents cathodic corrosion. Copyright2004, Intercept Technology Group No Oils, Sprays, VCI Paper or VCI Sponges Required with Intercept! Copyright2004, Intercept Technology Group Many companies apply light oils, greases, Cosmoline or other protective coatings to protect the metal products while in storage or during shipping. Corrosion Intercept eliminates the need for these coatings, which may require removal by solvents at the customer site. Significant savings in purchasing coatings and the reduced labor requirements may be realized. The customer does not have to spend hours cleaning the equipment and use hazardous solvents, which is a saving to them. Spare Parts – Supply Chain Storage / Shipment Requested Protection Period: 2 weeks to 2 years Shipment of goods world-wide. Partially opening by customs. Dramatic climatic changes. Copyright2004, Intercept Technology Group Metals and Assemblies Bags / Stretch / Shrink Copyright2004, Intercept Technology Group Automobile Supply Chain & CKD Applications Problem: Partially long storage periods before or after shipment under climatically difficult circumstances. Application:STATIC INTERCEPT® and CORROSION INTERCEPT® Films as alternative to Foil, VCI and wax-paper. All components are protected equally well. Tests have been performed by leading companies under realistic conditions for the complete period of time required. Further: Products are recyclable as colored PE and no further protection (Oil, Wax, etc.) is needed besides sufficient amount of desiccants (16 Units/m³). Only one non-shelf-life material needed to stock. Copyright2004, Intercept Technology Group Tested by US Army Tank Command Picatinny Arsenal Easy Handling – High Protection – Cost Savings A replacement for Mil 131J Foil (TACOM) Copyright2004, Intercept Technology Group Applications – Cast Iron Engine Blocks Ford Motor Company (SA) Engine blocks – 12 Month Storage test – No corrosion Copyright2004, Intercept Technology Group 1) Polyethylene bag 3) Blocks head bank down on Corex strips Copyright2004, Intercept Technology Group 2) SI bag with Corex separator 4) Cylinder blocks (6) with Desi Pak desiccant (4 sachets) 5) Perforated Corex sheet separating layers 7) Corex sheet on top Copyright2004, Intercept Technology Group 6) Blocks head bank up making 2nd layer. Desiccants added as per # 4 8) Close and tap SI bag 9) Close & tape plastic bag 11) Complete double layer Copyright2004, Intercept Technology Group 10) Re-start the process on top layer separated by wooded sheet board 12) Close bags as 8 & 9 - shrink wrap pallet Improvements seen Shipments to India and China changed to Intercept Padding was used to prevent punctures Copyright2004, Intercept Technology Group Ball Bearing Packs 3 Month Test – High Sulfur Environment In addition to being able to pack without Oils – the packaging helps prevent counterfeiting Copyright2004, Intercept Technology Group Applications – Ship Germany to Mexico ZF Lemförder Copyright2004, Intercept Technology Group Applications – BMW 15-Yr Storage BMW AG Copyright2004, Intercept Technology Group Application – Engine Manifolds Ship China to US The use of Intercept bags has allowed these engine manifolds to be shipped from China to the US with no protective oil coating – no oil to be applied, no steam cleaning at receiving, no corrosion failures Copyright2004, Intercept Technology Group ZF Sachs provided an inside view as to why they had decided to fully change to SI. Shipments were tested to: Brazil USA Mexico China Argentina South Africa Copyright2004, Intercept Technology Group Demonstration: Foil Copyright2004, Intercept Technology Group Demonstration: Intercept Intercept Bag – Simply rolled over And taped Can be reused! Copyright2004, Intercept Technology Group vs Foil Packaging 3 Minute pack 4 Minutes 38 Seconds to Seal Intercept Packaging 3 minute pack 20 Seconds to seal … more than 90% reduction in processing time ! Copyright2004, Intercept Technology Group … and of course better protection of the goods against corrosion; less damages due to opening of the package for customs checks; A clean and recyclable product, with less probability of injury. Copyright2004, Intercept Technology Group Cost Initial pricing on the product is competitive with other standard materials, the overall project cost has always come out lower! In detailed tests the following parameters were recorded 1. Procurement 2. Cost of storage (shelf-life) 3. Handling (Time, secondary components, etc.) 4. Effective (recorded damage improvement) Intercept always came out cheaper than the competition, with superior performance! Copyright2004, Intercept Technology Group Total Cost Analysis • • • • Recyclable as colored PE Meets European initiatives for product safety Safe for rubber and Polycarbonate storage Eliminates the need and requirement for oils, sponges, VCI separator sheets, and the required cleaning after oil coating • The only material consented by BMW for long term storage – Most VCIs and Dry method storage are limited to under 3 years – We have long term data available Copyright2004, Intercept Technology Group Product Variety Gusseted-Bags Stretch and Shrinkfilm Bags (With and without closing) Flat-Film MVTR- and EMI-Film Injection Molded Products Corrugated (up to 2.94) CD-Protection Nylon-Bags Laminated Fabric for covers Copyright2004, Intercept Technology Group Copyright2004, Intercept Technology Group