Global Supply Chain Risk Management strategies from China

advertisement

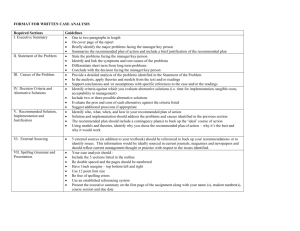

CCIRM 2011 Global Supply Chain Risk Management Strategies Christophe Cermolacce School of Economics and Management, Tongji University, Shanghai, China Ecole Supérieure de Commerce, Euromed Management, Marseille, France Anovo France, China’s branch representative Supervisor: Professor WU SI ZONG, Tongji University, Shanghai, China CCIRM 2011 Why SCRM strategies and China? • • • • China = world’s first exporter Lliterature = poor Last decade = numerous risk events Not well considered by managers and organizations CCIRM 2011 Goal • Based on Manuj and Mentzer 2008 Research • Refine, infirm, confirm their finding within the scope of SC with suppliers located in China CCIRM 2011 Methodology • Based on Manuj and Mentzer 2008 Research • Grounded theory • In-depth interviews with professionals CCIRM 2011 What is risk? • “A state of uncertainty where some of the possibilities involve a loss, catastrophe, or other undesirable outcome” Douglas Hubbard, 2007 • Risk = PxL or Risk =∑[PxL] (P: probability of the accident occurring, L: expected loss in case of the accident) CCIRM 2011 What is risk? Based on interviews • 4 dimensions 1. Potential losses 2. Likelihood of those losses 3. Speed 1. Speed of the event leading to loss 2. Speed at which losses happen 3. “How quickly the risk event is discovered” 4. Frequency CCIRM 2011 What is Global Supply Chain? • A complex system • Involves – – – – – – • Organizations (Companies and governments) People Technology Activities Information Resources Moving a product, service along a the chain between supplier and customer • An ever changing path • Risky CCIRM 2011 What is SCRM? Global Supply chain risk management is the identification and evaluation of risks and consequent losses in the global supply chain and implementation of appropriate strategies through a coordinated approach among supply chain members with the objective of reducing one or more of the following – losses, probability, speed of event, speed of losses, the time for detection of the events, frequency, or exposure – for supply chain outcomes that in turn lead to close matching of actual cost savings and profitability with those desired – Ila Manuj and John T, Mentzer, 2008 – CCIRM 2011 Global Supply Chain risk events and China 11. 1. Currency 12. 2. Transit time variability 3. Forecasts 13. 4. Quality 14. 5. Safety 15. 6. Business disruption 16. 7. Survival 17. 8. Ownership 18. 9. Culture 10.Dependency and opportunism Oil price fluctuation Raw material price fluctuation Non-payment situations Abandonment of goods Political/Legal Cheating Overzealousness Staff motivation CCIRM 2011 Global Supply Chain risk events and China CCIRM 2011 Supply Chain risk Management strategies Low supply risk High supply risk Low demand risk SlDl ShDl High demand risk SlDh ShDh Antecedents Temporal focus SC Flexibility SC environment -SlDl -ShDl -SlDh -ShDh Strategy selection Postponement Speculation Hedging Control/Share/Transfer Security Avoidance Team composition Risk Management Outcomes Total and Per Unit Cost Total and Per Unit Profit Average inventory Disruptions Total inbound Lead Time Delays to customers Stock-outs Fill Rate Premium Freight Usage Cash-to-cash cycle time Exposure Supply Chain Complexity Inter-organizational Learning CCIRM 2011 Supply Chain risk Management strategies Antecedents Temporal focus P0.a. The shorter the delays, the harder the management of risk P0.b. Shorter delay does not mean lower importance of risk P0.c. Delays hard to implement risk management strategies Flexibility •Adaptability •Alignment •Agility P0.d. Flexibility softens SCRM P0.e. Good relations with the members of the SC improves flexibility CCIRM 2011 Supply Chain risk Management strategies Postponement & Speculation P1. Supply chains facing SlDh and ShDh environments are more likely to adopt form postponement strategies than those facing SlDl and ShDl environments. P2. Supply chains facing SlDl and ShDl environments are more likely to adopt a speculation strategy than supply chains facing SlDh and ShDh. P1.b. Supply chains facing ShDh and environments are more likely to adopt manufacturing, logistics and form postponement strategies than those facing SlDl and ShDl environments CCIRM 2011 Supply Chain risk Management strategies Hedging Offsetting losses at some points by gains at others P3. Supply chains facing ShDl and ShDh environments are more likely to adopt hedging as compared to supply chains facing SlDl and SlDh environments CCIRM 2011 Supply Chain risk Management strategies Control/share/transfer •Control : forward or backward integration or virtual integration fthrough contracts and partnerships •Sharing : involves contracts and partnerships •Transfer : involves disintegration and outsourcing. P4. Supply chains facing ShDl environment are more likely to adopt backward integration, supply chains facing SlDh environment are more likely to adopt forward integration, and supply chains facing ShDh environments are more likely to adopt both backward and forward integration. P4.b. Supply chains facing ShDl environment are more likely to adopt virtual backward integration and higher control strategy by outsourcing than those facing SlDh and SlDl environments. CCIRM 2011 Supply Chain risk Management strategies Security P5. All types of supply chains will increase the use of security strategies. CCIRM 2011 Supply Chain risk Management strategies Avoidance Type1: avoid buying from China to reach a 0 risk situation Type2: reduce, prevent risk by controls P6. Supply chains operating in all types of environment adopt avoidance strategies. Type 1 avoidance strategy is adopted when a supply chain has an option not to enter a high demand or supply risk environment. Type 2 avoidance strategy is adopted when a supply chain has no option but to enter a high demand and/or supply risk environment CCIRM 2011 Supply Chain risk Management strategies Moderators Team composition P7. Team composition strongly affects the relationship between the antecedents and the strategy selected. Supply chain complexity P8. Greater supply chain complexity lessens the relationship between supply chain risk strategies and risk-related outcomes. CCIRM 2011 Implications • Risk events introduction • Testimonies for managers • 16 propositions – 5 on antecedents – 9 on strategies – 2 on moderators • Validation of Manuj and Mentzer’s models and propositions CCIRM 2011 Thank you, 谢谢