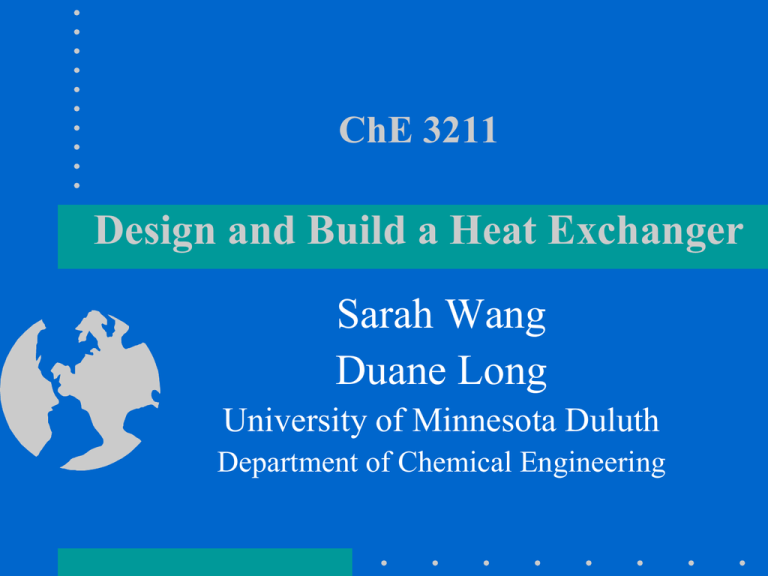

Build Your Own Heat Exchanger Information

advertisement

ChE 3211 Design and Build a Heat Exchanger Sarah Wang Duane Long University of Minnesota Duluth Department of Chemical Engineering Objectives • Provide hands-on experience • Provide an open-ended design problem • Develop a sense of engineering judgment Process • Prepare a detailed schematic • Solve design equations • Preliminary uncertainty analysis • Generate a Project Proposal Process Build your heat exchanger • Test your design • • • Calculate heat transfer parameters Calculate efficiency and the economic rating Prepare full/memo report and oral presentation Design Equations • Energy Balance q mh c p Thi Tho • Heat Transfer q UATh Tc UATln mn • Overall Heat Transfer Coefficient 1 UA 1 1 ... hi Ai ho Ao Design Objectives • Design a safe operating heat exchanger that meet the guidelines of OSHA and the Company • Minimize the cost and size Minimize the weight and length • Length (tube end to tube end) • Weight (dry weight) Design Objectives • Minimize the Cost and Size to enhance the Economic Rating E L W L W 100 – Min. Weight and Length • Effectiveness Factor Thi Tho Thi Tci Specifications Fluid is water • Tube side temperature change ≥ 20oC and ≤26°C Stream Cold Temperature (˚C) 15 2 Flow Rate (L/min) 0.60 ± 0.02 Hot 50 3 0.20 ± 0.02 Room air 21 ± 2 Hot ΔT 21 - 26 Materials • Only materials locally available – Schedule 40 PVC with max. dia = 4” – ¼” Copper tubing – ¼” Polyethylene tubing • Connections must accommodate ¼” compression fittings (Swagelok) • Use common building materials Construction 1. Design approved by the planning team 2. Meets the safety requirements of McCracken Industry, Inc and OSHA. 3. Hand tools will be made available. 4. Dept. will buy materials as specified in the “Call for Project Proposal” document – allow us time to get materials. 5. Safety first, sign release form after reading the Tool Safety information. Testing 1. Rig available for testing. 2. Your exchanger must be compatible with the test rig. 3. Make arrangements with Duane to test your heat exchanger. 4. Carefully gather data. Project Proposal 1. A Project Proposal shall be submitted in response to the “Call for Project Proposal” 2. The document “Call for Project Proposal” and information about the Heat Exchanger Design Project can be found at http://www.d.umn.edu/~dlong/studentbuildhtexc.html 3. Heat Exchanger Design should include at a minimum: a. b. c. d. Diagram of your heat exchanger; Size of PVC pipe (D x L) you will use for the shell; Length of copper tubing you will need; and The type and the number of each type of Swagelok fitting you will need to build your heat exchanger. Project Proposal 1. Submission of a Change Order 2. Information is found at the Web address on the previous slide and click on “Information required in a Project Proposal Change Order” a. Examples when a change order is needed b. Information to be included in a change order Due Dates 1. Tuesday Afternoon lab (Section 1) a. Project Proposal is due for submission to Dr. Sarah Wang with an electronic copy to Duane Long by 4:30 PM, Monday, October 29, 2012. Due Dates 3. Thursday Afternoon lab (Section 2) a. Project Proposal is due for submission to Dr. Sarah Wang with an electronic copy to Duane Long by 4:30 PM, Wednesday, October 31, 2012. Due Dates 1. If Duane does not receive an electronic copy, you may have to wait the first day of the lab until your kit containing the fittings is made up before you can start building your heat exchanger. Good Luck!