Tufts Annual Safety Training

advertisement

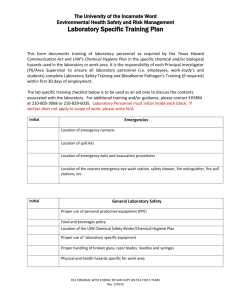

Tufts University Annual Safety Training What Will Be Covered • • • • • General Safety and Contact Information Hazardous Communication Hazardous Waste (RCRA) Chemical Hygiene Quiz General Safety Training Updated 2009 Environmental Health & Safety Staff Agnes (Aggie) Barlow - Radiation Safety Officer Julian Farland - Biosafety Officer Kathy Joseph - Biosafety Officer Thomas Kelley – Lab Safety Coordinator Stephen Larson – Director Peter Nowak - Industrial Hygiene & Occ. Safety Specialist Kimberly Parker - Biosafety Manager Shaun Savage – Lab Support & Compliance Specialist Natalie Viernes - Administrative Assistant Contacting EH&S • Non-Emergencies: • Posner Hall Room 105 • Individual Extensions • Main Number x6-3615 • Emergencies: • Contact campus police at x6-6911 or (617) 636-6911 • 24 hours day/7 days week Additional Important Numbers • Fire Marshals Office: Emergencies: x6-6911 or (617) 636-6911 Non-Emergencies: x7-3922 • Campus Police: Emergencies: x6-6911 or (617) 636-6911 Non-Emergencies: x6-6610 (Boston) Emergency Response Contact Tufts University Police! Fire (fire alarms) Chemical Spills Suspicious Person Medical Emergency Information to Provide: Name and extension of the person calling Exact location of emergency Description of emergency Extent of injury if any Type of chemical if a spill has occurred Correct spelling of the spilled chemical Emergency Evacuation Unless otherwise instructed by police or emergency personnel, evacuate when the alarm sounds. 1. If possible and without jeopardizing personal safety, shut off equipment. 2. Proceed to the closest exit; closing lab/office doors behind you. Note: Do not use elevators. 3. Proceed to designated area of gathering, away from the building. 4. Do not re-enter the building until directed by authorized personnel. Know Your Work Area! Fire Alarms Fire Extinguishers Safety Eyewash Safety Showers Multiple Exits Fire Extinguisher Hazardous Communication Updated 2009 Why Are You Here? • OSHA 29 CFR 1910.1200 Established in 1983 by the Federal Government to protect employees from hazardous materials. The standard requires companies which produce or use hazardous materials to provide employees with information and training on the proper use and handling of these materials. The primary objective is for the employee to know how and where to find specific information on hazardous materials. • Everyone working with or around hazardous materials has the right and responsibility to know the hazards in their work area! Why Me? Research Clinical Analytical Darkroom Printing Maintenance Construction Administration Custodial Shipping/Receiving Hazard Communication Plan • • • • • Responsibilities Chemical Inventories Training Labeling Material Safety Data Sheets (MSDS) Primary Responsibilities • EH&S: • Development and maintenance of the hazard communication program • Providing technical information and recommendations concerning hazardous chemicals, carcinogens and infectious agents. • Supervisors: • Training on specific job hazards prior to beginning work. • Notifying EH&S of the use and acquisition of hazardous materials Primary Responsibilities • Employees: • Adhere to established safety policies/procedures and to conduct operations in a safe manner. • Report unsafe conditions to supervisors and the EH&S. You have the right to a safe and healthy workplace; exercise this right, and understand that the ultimate responsibility for your health and safety lies with you. Hazards There are two general hazard classes that must be evaluated when assessing the safety of a material: Physical Hazards Health Hazards Physical Hazards • Compressed Gas – A gas that is stored under intense pressure in cylinders. • Flammability – A solid or liquid chemical that can serve as fuel sources to support a fire. • Reactivity – A substance’s susceptibility to undergo a chemical reaction or change that may result in an explosion, burning, and corrosive or toxic emissions. Examples: Air sensitive chemicals Water reactive chemicals Shock sensitive chemicals Light sensitive chemicals Health Hazards • Carcinogens – A substance that causes cancer. • Corrosives – A substance that causes visible destruction of living tissue at the site of contact. • Irritants – A substance that causes reversible inflammation of skin, eyes, or nasal passage. • Sensitizers – A substance that causes allergic reaction after repeated exposures. Note: Individual sensitivities vary. • Systemic Toxins – A toxin that targets a specific organ or system. Examples: Hepatotoxin-liver Nephrotoxins-kidneys Neurotoxins-nervous system Reproductive toxins-reproductive system Exposure • Primary routes of exposure: • • • • Inhalation Dermal Absorption Ingestion Injection • Working with or around hazardous substances does not necessarily mean that a person’s health will be effected. • Exposures can be controlled or eliminated by understanding the properties of chemicals in use. Utilizing protective equipment, ppe and/or substituting less-hazardous chemicals are examples. Labels and Signs Stock Chemicals: • It is the responsibility of the manufacturer or distributor to label each container containing a hazardous material with the following information: Name of hazardous substance Name and address of manufacturer The words “caution” or “danger” Statement of hazards First aid procedures Solutions: • It is the responsibility of the employee to label each container with the following information: Name of hazardous substance The words “caution” or “danger” Statement of hazards Signs: • Hazard signs should note area of hazard such as a cabinet or lab. Material Safety Data Sheets (MSDS) • Manufacturers of chemicals and/or products must provide an MSDS! • Locating an MSDS: • Hardcopy provided with shipment. • Manufacturers website • General websites (EH&S website) MSDS Information Identity of material, chemical name, and synonyms Hazardous components Physical data Physical and health hazards Exposure levels Symptoms of exposure and primary route of entry Fire Fighting Measures Safe handling and storage Control measures, PPE Spill and disposal procedures Miscellaneous Information “You have the right to a safe and healthy workplace; exercise this right, and understand that the ultimate responsibility for you health and safety lies with you!” Hazardous Waste Training (RCRA) Updated 2009 Why Are You Here? • Environmental Protection Agency 40 CFR 260-281 • Resource Conservation Recovery Act, RCRA, 1976 • Hazardous and Solid Waste Amendments, 1984 • Massachusetts Department of Environmental Protection 310 CMR 30.00 • Tufts University Internal Policy Tufts Generator Status • Large Quantity Generator • 90 day storage limit • Boston • Small Quantity Generator • 180 day storage limit • Medford, Grafton, HNRC, 200 Boston Ave., RBL What is a Hazardous Waste? • EPA listed waste: • D List, F List, K List, U List, P List • Characteristics: • • • • Ignitable (Flashpoints below 140˚F) Corrosive (pH 2 or below & 12.5 or higher) Toxic (Fail TCLP Testing) Reactive (Unstable compounds capable of violent chemical change) • Massachusetts Regulated Waste • University Policy When is it considered Waste? • Chemicals have become obsolete because of questionable purity or discontinued usage. • Shelf-life expiration dates have been exceeded. • Chemicals are stored in old, bulging, badly decomposed or damaged containers. • Chemicals have undergone visible change. Inherently Waste-Like Waste Storage (MAA) • There are multiple Main Accumulation Areas (MAA) located throughout the University for the long-term storage of chemical waste. • Free standing building, designated rooms, or flammable cabinets. • Additional measures to prevent release. • Managed by EH&S or designated personnel. Waste Storage (SAA) • Each site of generation will have a satellite accumulation area (SAA). • This includes: • • • • Secondary containment Signage Weekly inspection checklist Labels SAA Management (Labeling) • All containers must have a completed hazardous waste label. • • • • Contain “Hazardous Waste” Full Chemical Names Dated Full Hazard SAA Management (Containers) • Containers should be located in secondary containment. • Containers should be in adequate condition. No leaks. • Containers should be tightly closed. No parafilm or foil. • Containers should be compatible with waste. SAA Management • Non-waste material should not be located in the SAA. • Dated waste containers should be picked up and transported to a MAA within 3 days. Contact EH&S at x6-7615 for assistance. • There should not be multiple containers of the same waste in a SAA. • Keep SAA free of obstructions. • Updated inspection checklist. Date and Sign Weekly. Waste Pick-Up • Waste Pick-Up is needed when: • There is no longer a need for the container. • The container is old. • The container is roughly 85% full. • Contact EH&S at x6-7615 for assistance. • • • • Name/make up of waste. Quantity Building room and number Principal investigator/contact name and extension. Palm Pilot Program • Internal inspection program focused on: • Assuring compliance • Educating personnel • Simplify hazardous waste management • Conducted unannounced every 2-3 months. • Conducted by outside contracted vendor. • Provide EH&S and principal investigators/supervisors with report. Universal Waste • Universal Waste Rule 40 CFR 273 • Provides less stringent management standards for: • • • • • Mercury containing lamps. Batteries Pesticides Mercury devices. Ballasts • Contact EH&S for assistance at x6-7615. Conclusion • This is a required annual training for personnel who generate or manage hazardous waste. • Failure to comply with protocols outlined in this training could result in criminal and monetary penalties against the university and/or individual. Chemical Hygiene Basic Training Updated 2009 Introduction Occupational Safety and Health Administration (OSHA) enacted the Occupational Exposure to Chemicals in Laboratories Standard in 1990. This standard applies to all employees engaged in the laboratory use of hazardous chemicals at Tufts University. Roles and Responsibilities • Provost- The University Provost has the ultimate legal responsibility and accountability for chemical hygiene within the institution. • Director Of Health and Safety appoints Chemical Hygiene officers, works with Provost to determine needs and directions for Chemical Hygiene at Tufts. • Chemical Hygiene Officer(s) Work with the Laboratory Safety Committee, administrators and other employees to develop and implement appropriate chemical hygiene policies and practices; • Supervisors Ensure that laboratory workers know and follow the chemical hygiene rules, that protective equipment is available and in working order, and that appropriate training has been provided; • Laboratory Worker Planning and conducting each operation in accordance with the institutional chemical hygiene procedures; Employee Information and Training • Employee safety information and training program is reviewed regularly. • Chemical Hygiene training should be conducted prior to working in the lab. • Basic refresher training is offered annually by the Environmental Health and Safety Department, either on line or via traditional classroom style trainings. • It is the responsibility of the PI or Supervisor to conduct lab and tasks specific training that builds on the general concepts identified in the basic chemical hygiene trainings. Chemical Fume Hoods • Chemical Fume Hood: • Do you understand how your hood works to protect you? • Can you distinguish between a biological safety cabinet and a chemical fume hood? • Do you know that an open lab door, high winds, or even heavy traffic in front of the hood can reduce performance? • Will you know if it stops working? And who to contact? Never leave experiments unattended. • Emergency Drenching Facilities Eyewash Station: • Do you know where the nearest eyewash station is located? • Do you know how to use it? • Is it free from obstructions? • Is the eyewash being flushed weekly to drain sediment buildup and rust? • Drench Shower: • Do you know where the nearest eyewash station is located? And is it within 10 seconds from your work area? • Is it free from obstructions? • Are there any electrical hazards in the area? • Is it being inspected semi-annually by the Facilities Dept? Safety Showers Chemical Spill Kit • Every laboratory has at least one chemical spill kit. • Absorbent socks • Absorbent pads • Hazardous waste label • Know the location of the spill kit and assure it is constantly stocked. • Understand which chemicals can and cannot be cleaned up safety. • Contact EH&S for assistance. Personal Protective Equipment Personal Protective Equipment such as gloves, safety glasses, and lab coats should be provided by the lab or department. Gloves: • No one glove material is best for all chemicals. • Choose the glove with the lowest permeability for the chemical you are using. • Glove-Chemical compatibility charts • Material Safety Data Sheets • Environmental Health and Safety Department • Reusable gloves should be inspected prior to use. • Remove lab gloves and dispose appropriately to avoid exposure. Personal Protective Equipment Goggles/Glasses: • • • Similar to gloves, be sure eye protection is appropriate for the hazard. Safety glasses alone are not always enough to protect against chemical splashes and flying debris. Goggles or face shields may be needed. Prescription are not enough to protect against chemical splashes and flying debris. Lab Coats: • • • • Lab coats, coveralls, or aprons should be used where there is danger to the skin. Every person working in a laboratory must be wearing a lab coat. Lab coats should not be worn in common areas such as halls, elevators, and lunch rooms. Laundry services should be provided by the lab or department. General Lab Hygiene • Do not eat or drink in a laboratory. • Do not wear open toe shoes in a laboratory. • Do not wear skirts or shorts that expose your legs when working in a laboratory. • Loose clothing and long hair should be confined. • Understand potential hazards associated with wearing jewelry. • Mouth pipetting is prohibited. • Wash and clean work areas when work is complete. Cryogenic Liquids • • • • Always wear adequate protective clothing, eye and face protection and heat resistant gloves when dealing with cryogenic liquids. Store liquid nitrogen, dry ice and any other liquefied gases in well-ventilated areas. Do not store in walk-in cold rooms, as these are not ventilated Seal sample tubes tightly before storing in liquid nitrogen. Improper sealing of tubes can cause an explosion upon removal from liquid nitrogen temperatures. Shipping Materials No one should ship or participate in the packaging or preparation of biological or chemical material without completing the required training. Failure could result in penalties of $30,000. Pending the content, various levels of training is needed. Training for shipment of hazardous material can be arranged through the EH&S Department. Scheduling of this training should be done well in advance of the projected shipment date. We thank you for your time and cooperation in helping Tufts University and yourself maintain continued compliance with applicable regulatory requirements. Completion of this training is an annual requirement. All material will be updated as required. Questions or comments can be directed to the Environmental Health and Safety Dept. x6-3516.