Document

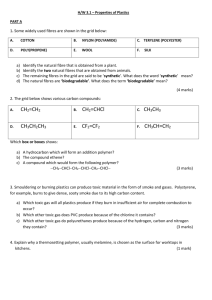

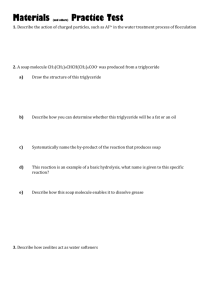

advertisement

24 Organic Chemistry William H. Brown & Christopher S. Foote 24-1 24 Organic Polymer Chemistry Chapter 24 24-2 24 Organic Polymer Chem. Polymer: from the Greek, poly + meros, many parts • any long-chain molecule synthesized by bonding together single parts called monomers Monomer: from the Greek, mono + meros, single part • the simplest nonredundant unit from which a polymer is synthesized Plastic: a polymer that can be molded when hot and retains its shape when cooled 24-3 24 Organic Polymer Chem Thermoplastic: a polymer that can be melted and molded into a shape that is retained when it is cooled Thermoset plastic: a polymer that can be molded when it is first prepared but, once it is cooled, hardens irreversibly and cannot be remelted 24-4 24 Notation & Nomenclature Show the structure by placing parens around the repeat unit • n = average degree of polymerization synthesized from n synthesized from Cl Polystyrene Styrene n Poly(vinyl chloride) (PVC) Cl Vinyl chloride 24-5 24 Notation & Nomenclature To name a polymer, prefix poly to the name of the monomer from which the it is derived • if the name of the monomer is one word, no parens are necessary • for more complex monomers or where the name of the monomer is two words, enclose the name of the monomer is parens, as for example poly(vinyl chloride) or poly(ethylene terephthalate) 24-6 24 Molecular Weight All polymers are mixtures of individual polymer molecules of variable MWs • number average MW: count the number of chains of a particular MW, multiply each number by the MW, sum these values, and divide by the total number of polymer chains • weight average MW: record the weight of each chain of a particular length, sum these weights, and divide by the total weight of the sample 24-7 24 Morphology Polymers tend to crystallize as they precipitate or are cooled from a melt Acting to inhibit crystallization are their very large molecules, often with complicated and irregular shapes, which prevent efficient packing into ordered structures As a result, polymers in the solid state tend to be composed of ordered crystalline domains and disordered amorphous domains 24-8 24 Morphology High degrees of crystallinity are found in polymers with regular, compact structures and strong intermolecular forces, such as hydrogen bonds and dipolar interactions • as the degree of crystallinity increases, the polymer becomes more opaque due to scattering of light by the crystalline regions Melt transition temperature, Tm: the temperature at which crystalline regions melt • as the degree of crystallinity increases, Tm increases 24-9 24 Morphology Highly amorphous polymers are sometimes referred to as glassy polymers • because they lack crystalline domains that scatter light, amorphous polymers are transparent • in addition they are weaker polymers, both in terms of their greater flexibility and smaller mechanical strength • on heating, amorphous polymers are transformed from a hard glass to a soft, flexible, rubbery state Glass transition temperature, Tg: the temperature at which a polymer undergoes a transition from a hard glass to a rubbery solid 24-10 24 Morphology Example: poly(ethylene terephthalate), abbreviated PET or PETE, can be made with % crystalline domains ranging from 0% to 55% O O O O n Poly(ethylene terephthalate) 24-11 24 Morphology Completely amorphous PET is formed by cooling the melt quickly • PET with a low degree of crystallinity is used for plastic beverage bottles By prolonging cooling time, more molecular diffusion occurs and crystalline domains form as the chains become more ordered • PET with a high degree of crystallinity can be drawn into textile fibers and tire cords 24-12 24 Step-Growth Polymers Step-growth polymerization: a polymerization in which chain growth occurs in a stepwise manner between difunctional monomers we discuss five types of step-growth polymers • • • • • polyamides polyesters polycarbonates polyurethanes epoxy resins 24-13 24 Polyamides Nylon 66 (from two six-carbon monomers) O HO OH + O Hexanedioic acid (Adipic acid) H 2N N H2 heat 1,6-Hexanediamine (Hexamethylenediamine) O O N H Nylon 66 H N n • during fabrication, nylon fibers are cold-drawn to about 4 times their original length, which increases crystallinity, tensile strength, and stiffness 24-14 24 Polyamides • the raw material base for the production of nylon 66 is benzene, which is derived from cracking and reforming of petroleum 3 H2 catalyst Benzene O2 catalyst Cyclohexane O OH + Cyclohexanol HN O 3 Cyclohexanone COOH COOH Hexanedioic acid (Adipic acid) 24-15 24 Polyamides • adipic acid is in turn the starting material for the synthesis of hexamethylenediamine O N H4 + - O O - N H4 + heat O Ammonium hexanedioate (Ammonium adipate) O H 2N N H2 O Hexanediamide (Adipamide) 4 H2 catalyst H 2N N H2 1,6-Hexanediamine (Hexamethylenediamine) 24-16 24 Polyamides Nylons are a family of polymers, the two most widely used of which are nylon 66 and nylon 6 • nylon 6 is synthesized from a six-carbon monomer O n N H 1. partial hydrolysis Caprolactam H O N 2. heat n Nylon 6 • nylon 6 is fabricated into fibers, brush bristles, highimpact moldings, and tire cords 24-17 24 Polyamides Kevlar is a polyaromatic amide (an aramid) O nHOC O COH 1,4-Benzenedicarboxylic acid (Terephthalic acid) O C + nH 2 N NH2 1,4-Benzenediamine (p-Phenylenediamine) O CNH Kevlar NH n + 2 nH 2 O • cables of Kevlar are as strong as cables of steel, but only about 20% the weight. Kevlar fabric is used for bulletproof vests, jackets, and raincoats 24-18 24 Polyesters Poly(ethylene terephthalate), abbreviated PET or PETE, is fabricated into Dacron fibers, Mylar films, and plastic beverage containers O O + HO OH heat HO OH 1,4-Benzenedicarboxylic acid 1,2-Ethanediol (Ethylene glycol) (Terephthalic acid) O O O O n Poly(ethylene terephthalate) (Dacron, Mylar) + 2 nH2 O 24-19 24 Polyesters • ethylene glycol is obtained by air oxidation of ethylene followed by hydrolysis to the glycol CH2 = CH2 Ethylene O O2 catalyst CH2 -CH 2 Oxirane (Ethylene oxide) H+ , H2 O HOCH2 CH2 OH 1,2-Ethanediol (Ethylene glycol) • terephthalic acid is obtained by catalyzed air oxidation of petroleum-derived p-xylene H3 C CH3 p-Xylene O O O2 COH catalyst HOC Terephthalic acid 24-20 24 Polycarbonates Lexan is a tough transparent polymer with high impact and tensile strengths and retains its shape over a wide temperature range • it is used in sporting equipment, such as bicycle, football, and snowmobile helmets as well as hockey and baseball catcher’s masks • it is also used in the manufacture of safety and unbreakable windows 24-21 24 Polycarbonates • to make Lexan, an aqueous solution of the sodium salt of bisphenol A is brought into contact with a solution of phosgene in CH2Cl2 in the presence of a phasetransfer catalyst O CH3 + Na - O CH3 Disodium salt of Bisphenol A O- Na + + Cl Cl Phosgene O CH3 O CH3 Lexan (a polycarbonate) O n + 2 NaCl 24-22 24 Polyurethanes A urethane, or carbamate, is an ester of carbamic acid, H2NCH2COOH • they are most commonly prepared by treatment of an isocyanate with an alcohol O RN = C= O + An isocyanate R' OH RN HCOR' A carbamate Polyurethanes consist of flexible polyester or polyether units (blocks) alternating with rigid urethane units (blocks) • the rigid urethane blocks are derived from a diisocyanate 24-23 24 Polyurethanes • the more flexible blocks are derived from low MW polyesters or polyethers with -OH groups at the ends of each polymer chain O= C=N CH3 N = C= O + nHO- polymer-OH Low-molecular-weight polyester or polyether 2,6-Toluene diisocyanate O CN H CH 3 O N HCO- polymer- O n A polyurethane 24-24 24 Epoxy resins Epoxy resins are materials prepared by a polymerization in which one monomer contains at least two epoxy groups • within this range, there are a large number of polymeric materials, and epoxy resins are produced in forms ranging from low-viscosity liquids to highmelting solids 24-25 24 Epoxy Resins • the most widely used epoxide monomer is the diepoxide prepared by treating 1 mole of bisphenol A with 2 moles of epichlorohydrin CH 3 O O - Na + + Na + - O Cl Epichlorohydrin CH 3 the disodium salt of bisphenol A CH 3 O O O O CH 3 A diepoxide 24-26 24 Epoxy Resins • treatment of the diepoxide with a diamine gives the resin CH3 O O O O CH3 A diepoxide NH 2 H2 N A diamine CH3 OH O OH O CH3 An epoxy resin H N N H n 24-27 24 Thermosets Baelekite was one of the first thermosets OH OH + CH2 O Phenol OH OH Formaldehyde OH OH Baekelite 24-28 24 Chain-Growth Polymers Chain-growth polymerization: a polymerization that involves sequential addition reactions, either to unsaturated monomers or to monomers possessing other reactive functional groups Reactive intermediates in chain-growth polymerizations include radicals, carbanions, carbocations, and organometallic complexes 24-29 24 Chain-Growth Polymers We concentrate on chain-growth polymerizations of ethylene and substituted ethylenes R An alkene R n • on the following two screens are several important polymers derived from ethylene and substituted ethylenes, along with their most important uses 24-30 24 Polyethylenes Monomer Formula Common Name Polymer Name(s) and Common Uses CH2 = CH2 Ethylene Polyethylene, Polythene; break-resistant containers and packaging materials CH2 = CHCH 3 Propylene Polypropylene, Herculon; textile and carpet fibers CH2 = CHCl Vinyl chloride Poly(vinyl chloride), PVC; construction tubing CH2 = CCl 2 1,1-Dichloroethylene Poly(1,1-dichloroethylene), Saran; food packaging 24-31 24 Polyethylenes CH2 = CHCN Acrylonitrile Polyacrylonitrile, Orlon; acrylics and acrylates CF2 = CF2 Tetrafluoroethylene Poly(tetrafluoroethylene), PTFE; nonstick coatings CH2 = CHC6 H5 Styrene Polystyrene, Styrofoam; insulating materials CH2 = CHCOOEt Ethyl acrylate CH2 = CCOOCH 3 Methyl methacrylate Poly(ethyl acrylate); latex paints Poly(methyl methacrylate), Plexiglas; glass substitutes CH3 24-32 24 Radical Chain-Growth Among the initiators used for radical chaingrowth polymerization are diacyl peroxides, which decompose as shown on mild heating O O O O Dibenzoyl peroxide O 2 A benzoyloxy radical O 2 + 2 CO 2 A phenyl radical 24-33 24 Radical Chain-Growth Another common class of initiators are azo compounds, which also decompose on mild heating or with absorption of UV light or h N C : : N N C N Azoisobutyronitrile (AIBN) 2 • N C + : N N: Alkyl radicals 24-34 24 Radical Chain-Growth Radical polymerization of a substituted ethylene • chain initiation or h In-In In 2 In + In R R • chain propagation In In + R + In R R R R In n R R R n R etc. 24-35 24 Radical Chain-Growth • chain termination radical coupling In R 2 In R n n R R In n R R disproportionation In R n + R H In R n R 24-36 24 Radical Chain-Growth Radical reactions with double bonds almost always gives the more stable (the more substituted) radical • because additions are biased in this fashion, polymerizations of vinyl monomers tend to yield polymers with head-to-tail linkages R R R R R R R R head-to-tail linkages R R head-to-head linkage 24-37 24 Radical Chain-Growth Chain-transfer reaction: the reactivity of an end group is transferred from one chain to another, or from one position on a chain to another position on the same chain • polyethylene formed by radical polymerization exhibits a number of butyl branches on the polymer main chain • these butyl branches are generated by a “back-biting” chain-transfer reaction in which a 1° radical end group abstracts a hydrogen from the fourth carbon back • polymerization then continues from the 2° radical 24-38 24 Radical Chain-Growth H A six-membered transition state leading to 1,5-hydrogen abstraction H nCH2 = CH2 n 24-39 24 Radical Chain-Growth The first commercial polyethylenes produced by radical polymerization were soft, tough polymers known as low-density polyethylene (LDPE) • LDPE chains are highly branched due to chain-transfer reactions • because this branching prevents polyethylene chains from packing efficiently, LDPE is largely amorphous and transparent • approx. 65% is fabricated into films for consumer items such as baked goods, vegetables and other produce, and trash bags 24-40 24 Ziegler-Natta Polymers Ziegler-Natta chain-growth polymerization is an alternative method that does not involve radicals • Ziegler-Natta catalysts are heterogeneous materials composed of a MgCl2 support, a Group 4B transition metal halide such as TiCl4, and an alkylaluminum compound CH2 = CH2 Ethylene T iCl 4/ Al( CH2 CH3 ) 2 Cl Mg Cl2 n Polyethylene 24-41 24 Ziegler-Natta Polymers Mechanism of Ziegler-Natta polymerization Step 1: formation of a titanium-ethyl bond Mg Cl2 / TiCl 4 particle Ti Cl + Cl Cl A l Ti + Cl A l Diethylaluminum chloride Step 2: insertion of ethylene into the Ti-C bond Ti + CH2 = CH2 Ti 24-42 24 Ziegler-Natta Polymers Polyethylene from Ziegler-Natta systems is termed high-density polyethylene (HDPE) • it has a considerably lower degree of chain branching than LDPE and a result has a higher degree of crystallinity, a higher density, a higher melting point, and is several times stronger than LDPE • appox. 45% of all HDPE is blow-molded into containers • with special fabrication techniques, HDPE chains can be made to adopt an extended zig-zag conformation. HDPE processed in this manner is stiffer than steel and has 4x the tensile strength! 24-43 24 Polymer Stereochemistry There are three alternatives for the relative configurations of stereocenters along the chain of a substituted ethylene polymer R H R H R H R H R H Isotactic polymer (identical configurations) R H H R R H H R R H Syndiotactic polymer (alternating configurations) R H R H R H R H H R Atactic polymer (random configurations) 24-44 24 Polymer Stereochemistry In general, the more stereoregular the stereocenters are (the more highly isotactic or syndiotactic the polymer is), the more crystalline it is • the chains of atactic polyethylene, for example, do not pack well and the polymer is an amorphous glass • isotactic polyethylene, on the other hand, is a crystalline, fiber-forming polymer with a high melt transition 24-45 24 Ionic Chain-Growth May be either anionic or cationic polymerizations • cationic polymerizations are most common with monomers with electron-donating groups OR Styrene Isobutylene Vinyl ethers SR Vinyl thioethers • anionic polymerizations: most common with monomers with electron-withdrawing groups CN Styrene COOR Alkyl methacrylates COOR Alkyl acrylates CN Acrylonitrile COOR Alkyl cyanoacrylates 24-46 24 Anionic chain-Growth Anionic polymerization can be initiated by addition of a nucleophile, such as methyl lithium, to an activated alkene R' R' R Li + R' R + Li + R' R R' etc. 24-47 24 Anionic Chain-Growth An alternative method for initiation involves a one-electron reduction of the monomer by Li or Na to form a radical anion which is either reduced or dimerized to a dianion Li Li + Butadiene A radical anion radical coupling to form a dimer Li Li + Li Li A dimer dianion + + Li + + A dianion 24-48 24 Anionic Chain-Growth To improve the efficiency of anionic polymerizations, soluble reducing agents such as sodium naphthalide are used + Na THF N a+ : Naphthalene Sodium naphthalide (a radical anion) • the naphthalide radical anion is a powerful reducing agent and, for example, reduces styrene to a radical anion which couples to give a dianion 24-49 24 Anionic Chain-Growth Na + Styrene Na + Na + Na + A s tyryl radical anion A dis tyryl dianion • the styryl dianion then propagates polymerization at both ends simultaneously 24-50 24 Anionic Chain-Growth propagation of the distyryl dianion 1. 2n N a+ N a+ 2 . H O 2 A distyryl dianion n n Polystyrene 24-51 24 Anionic Chain-Growth Living polymer: a polymer chain that continues to grow without chain-termination steps until either all of the monomer is consumed or some external agent is added to terminate the chains • after consumption of the monomer under living anionic conditions, electrophilic agents such as CO2 or ethylene oxide are added to functionalize the chain ends 24-52 24 Anionic Chain-Growth • termination by carboxylation : n N a+ CO 2 n COO- Na + H3 O + n COOH 24-53 24 Cationic Chain-Growth The two most common methods for initiating cationic polymerization are • reaction of a strong protic acid with the monomer • abstraction of a halide from the organic initiator by a Lewis acid Initiation by a protic acid requires a strong acid with a nonnucleophilic anion in order to avoid addition to the double bond • suitable acids include HF/AsF5 and HF/BF3 24-54 24 Cationic Chain-Growth • initiation by a protic acid R R R H+ BF 4 - H3 C R + BF4 R R H3 C R R RR n + R BF4 - R • Lewis acids used for initiation include BF3, SnCl4, AlCl3, Al(CH3) 2Cl, and ZnCl2 24-55 24 Cationic Chain-Growth • initiation Cl + SnCl 4 + SnCl 5 - 2-Chloro-2-phenylpropane • propagation + + + 2-Methylpropene n + n + 24-56 24 Cationic Chain-Growth • chain termination n + H2 O SnCl 5 - n OH + H+ SnCl 5 - 24-57 24 Prob 24.5 Name each polymer, and draw the structure of the monomer(s) that might be used to make it. (a) n (b) O n (c) n O (d) O (f) O n O O O (g) n CF2 n CF3 O (e) CF n H N (h) O O N n H CH2 Cl 24-58 24 Prob 24.7 Draw a structural formula for the polymer formed in each reaction. O O (a) Me O OMe + HO O O (b) Me O (c) O OH H+ OH OMe + HO CF3 SO3 H OH H+ (d) O KOH 24-59 24 Prob 24.8 Propose reagents and experimental conditions for the conversion of furan to hexamethylenediamine. oat hulls, corn H 2 SO 4 cobs, sugar cane H2 O stalks, etc (1) O Furan Zn-Cr-Mo catalyst O O CH Furfural (2) O Tetrahydrofuran (THF) N C( CH2 ) 4 C N Hexanedinitrile (Adiponitrile) Cl( CH2 ) 4 Cl (3) 1,4-Dichlorobutane (4) H2 N( CH 2 ) 6 N H 2 1,6-Hexanediamine (Hexamethylenediamine) 24-60 24 Prob 24.9 Propose reagents for the conversion of 1,3-butadiene to hexamethylenediamine. CH2 = CHCH = CH 2 Butadiene (1) ClCH 2 CH= CHCH2 Cl (2) 1,4-Dichloro-2-butene N CCH2 CH= CHCH2 C N 3-Hexenedinitrile (3) H2 N( CH 2 ) 6 N H2 1,6-Hexanediamine (Hexamethylenediamine) 24-61 24 Prob 24.10 Propose reagents and experimental conditions for the conversion of butadiene to adipic acid. ? 1,3-Butadiene H OOC COOH Hexanedioic acid (Adipic acid) 24-62 24 Prob 24.12 Propose a mechanism for the step-growth reaction in this polymerization. O n CH3 OC O COCH 3 + Dimethyl terephthalate O C 275°C nHOCH2 CH 2 OH Ethylene glycol O COCH 2 CH2 O n Poly(ethylene terephthalate) + 2 nCH3 OH Methanol 24-63 24 Prob 24.13 Identify the monomer(s) required for the synthesis of each step-growth polymer. (a) O C O C-O- CH2 CH2 O n Kodel (a polyester) (b) O O C( CH2 ) 6 C N H CH2 NH n Quiana (a polyamide) 24-64 24 Prob 24.14 Draw a structural formula for the repeating unit of Nomex. H 2N N H2 + 1,3-Benzenediamine Cl Cl polymerization Nomex O O 1,3-Benzenedicarbonyl chloride 24-65 24 Prob 24.15 Propose a mechanism for this Beckmann rearrangement which converts cyclohexanone oxime to caprolactam, the monomer from which nylon 6 is synthesized. O N OH N H2 OH Cyclohexanone Cyclohexanone oxime O H2 SO 4 NH Caprolactam 24-66 24 Prob 24.17 Propose a mechanism for the formation of this polycarbonate. O F + N a2 CO 3 F An aromatic difluoride Sodium carbonate O O O O n + 2 N aF A polycarbonate 24-67 24 Prob 24.18 Propose a mechanism for the formation of this polyurea. To simplify, consider the reaction of one -NCO group with one -NH2 group. OCN N CO + 1,4-Benzenediisocyanate H 2N N H2 1,2-Ethanediamine O O H N N N N n H H H Poly(ethylene phenylurea) 24-68 24 Prob 24.19 When equal molar amounts of these two monomers are heated, they form an amorphous polyester. Under these conditions, polymerization is regioselective for the 1°-OH groups. Draw a structural formula for the repeat unit of this polyester. O OH O + HO O Phthalic anhydride OH heat a polyester 1,2,3-Propanetriol (Glycerol) 24-69 24 Prob 24.21 Propose a mechanism for formation of this polymer. O O O O base + H2N N H2 N N n 24-70 24 Prob 24.22 Draw a structural formula for the polymer resulting from base-catalyzed polymerization of each monomer. Will the polymer by optically active? O (a) O O O (S)-(+)-Lactide (b) O (R)-Propylene oxide 24-71 24 Prob 24.23 The polymer on the left is an insoluble, opaque material that is difficult to process into shapes. The polymer on the right is an transparent material that is soluble in a number of organic solvents. Explain the difference in physical properties between the two in terms of their structural formulas. O O O n Poly(3-hydroxybutanoic acid) O On O m Poly(3-hydroxybutanoic acid 3-hydroxyoctanoic acid) copolymer 24-72 24 Prob 24.25 Draw a structural formula for the repeat unit of the polymer formed in each reaction. (a) O O Li AIBN 70°C (b) CN 24-73 24 Prob 24.26 Select the member of each pair that is more reactive toward cationic polymerization. (a) (b) or OCH3 OCH3 (c) (d) CH3 O or OCCH 3 O or or 24-74 24 Prob 24.33 Natural rubber is the all-cis polymer of isoprene. Draw a structural formula for the repeat unit of natural rubber. Poly(2-methyl-1,3-butadiene) (Polyisoprene) 24-75 24 Prob 24.34 Radical polymerization of styrene gives a linear polymer. Show by drawing structural formulas how incorporation of a few percent 1,4-divinylbenzene in the polymerization mixture gives a cross-linked polymer. + Styrene a copolymer of styrene and divinylbenzene 1,4-Divinylbenzene 24-76 24 Prob 24.37 From what two monomer units is this polymer made? C N C N 24-77 24 Prob 24.38 Draw a structural formula for the repeat unit in the polymer formed by ring-opening metathesis polymerization of each monomer. O (a) (b) (c) O (d) 24-78 24 Organic Polymer Chemistry End Chapter 24 24-79