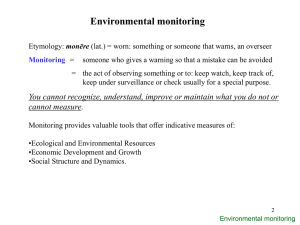

GASU - GLAST at SLAC

GLAST LAT Project DOE Review, February 18, 2005

Gamma-ray Large

Area Space

Telescope

GLAST Large Area Telescope:

DOE Review

4.1.7 DAQ

G. Haller

SLAC haller@slac.stanford.edu

(650) 926-4257

4.1.7 DAQ & FSW V1 1

GLAST LAT Project

Contents

• Overview - Production & Testing - Schedule

– TEM/TPS Flight Units

– PDU Flight Units

– GASU Flight Units

– SIU/EPU Flight Units

• Testbed

• Installation & Test Support

• Budget

DOE Review, February 18, 2005

4.1.7 DAQ & FSW V1 2

GLAST LAT Project DOE Review, February 18, 2005

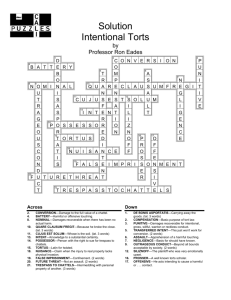

LAT Electronics

ACD

TKR Front-End Electronics (MCM)

ACD Front-End Electronics (FREE)

CAL Front-End Electronics (AFEE) TKR

–

–

CAL

Global-Trigger/ACD-EM/Signal-Distribution Unit*

Spacecraft Interface

Units (SIU)*

Storage Interface

Board (SIB):

Spacecraft interface, control & telemetry

LAT control CPU

–

LAT Communication

Board (LCB): LAT command and data interface empty empty empty

EPU-1

SIU*

SIU*

GASU*

Power Dist. Unit*

EPU-3 empty empty

EPU-2

16 Tower Electronics Modules & Tower

Power Supplies

3 Event-Processor Units (EPU) (2 + 1 spare)

–

Event processing CPU

– LAT Communication Board

– SIB

Power-Distribution Unit (PDU)*

–

Spacecraft interface, power

– LAT power distribution

– LAT health monitoring

4.1.7 DAQ & FSW

* Primary & Secondary Units shown in one chassis

V1 3

GLAST LAT Project DOE Review, February 18, 2005

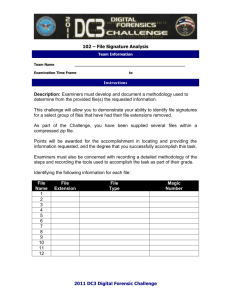

TEM/TPS Mounted to CAL

TKR not shown

LAT GRID with 16 CAL/TEM/TPS Modules

CAL

4.1.7 DAQ & FSW V1

TEM

TPS

4

GLAST LAT Project DOE Review, February 18, 2005

Tower Electronics Module/Tower Power Supply

• Tower Electronics Module: Main DAQ module, one on each tower

– Controls and reads out data from TKR

MCM and CAL AFEE front-end electronics

– Assembles CAL and TKR event fragments to tower event

•

Tower Power Supply module, one on each tower

– Input 28V

–

Generates low-noise voltages for

• TKR (2.65V analog, 2.65V Digital)

• CAL (3.3V analog, 3.3V digital)

•

TEM (3.3V and 2.5V digital)

• TKR Bias (20V-140V programmable)

• CAL (20V to 90V programmable)

Tower

Electronics

Module (TEM) before coating/staking

TEM

Tower Power Supply

(TPS) before coating/staking

4.1.7 DAQ & FSW V1

Shown upside-down TPS

5

GLAST LAT Project DOE Review, February 18, 2005

TEM/TPS Status & Schedule

• Status

– Three Flight Tower-Electronics Modules/Tower Power Supplies received

• Fully assembled

•

Thermal-cycled

• Vibration tested (one of them to qualification levels)

• One unit finished thermal-vacuum testing

• One unit in thermal-vacuum testing

• Both units finished EMI/EMC testing

•

No issues/problems

– Balance of 19 TEM/TPS in surface-mount assembly at vendor

• Schedule

– 2/17/05 First TEM/TPS to I&T

– 2/25/05 Second TEM/TPS to I&T

– 4/1/05 Third TEM/TPS to I&T

– 4/22/05 Fourth TEM/TPS to I&T

• One week lag between delivery of consecutive assemblies

– 7/26/05 Last TEM/TPS to I&T

4.1.7 DAQ & FSW V1 6

GLAST LAT Project DOE Review, February 18, 2005

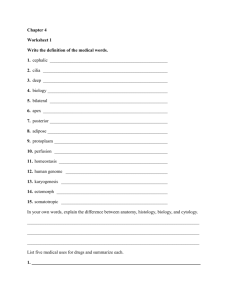

PDU & GASU Mounted on LAT

GASU

4.1.7 DAQ & FSW V1

PDU

7

GLAST LAT Project DOE Review, February 18, 2005

Power Distribution Module (PDU)

EM PDU enclosure with primary/redundant PDU circuit cards, no coating/staking

• Primary and Redundant Circuits in one Enclosure

– Receives Primary and Redundant 28-V from spacecraft

–

Each, primary and redundant PDU can select between primary and redundant spacecraft power

– Filters 28V

– Turns on/off 28V to 16 towers and 3 EPU’s under program control

–

Protects PDU and down-stream circuits from overcurrent and under-voltage

• Over-current via poly-switches

• Under-voltage via custom circuit in each poweron branch

–

Receives command/clock from GASU

–

Digitizes voltages/temperatures from > 150 sources

•

Includes temperatures from radiators, GRID; used for thermal control

– Reads back data to SIU via GASU

– Provides PDU DAQ voltage and temperature analog data to spacecraft for monitoring

4.1.7 DAQ & FSW V1 8

GLAST LAT Project DOE Review, February 18, 2005

PDU Status and Schedule

• Status

– Design/documentation complete

– Enclosures fabricated

– All parts received (except recalled International Rectifier regulator, due end of February)

– Assembly contract awarded

– All parts kitted and audited by assembly vendor

– Assembly started

• Schedule for Flight Unit

– 5/15/05 Precoat PDU assembly ready for electrical test

– 5/30/05 Complete assembly ready for environmental test

– 7/1/05 Flight PDU to I&T

4.1.7 DAQ & FSW V1 9

GLAST LAT Project

GASU

• Primary and Redundant Circuits in one Enclosure

– Contains two types of circuit card assemblies

•

GASU Power Supply CCA

•

GASU DAQ Board CCA

–

GASU Power Supply

•

Receives 28-V supply voltages for

– Primary and redundant DAQ board, generates 3.3V and 2.5v

– ACD FREE cards

» Filtering for 28-V

» 3.3V regulation

– GASU DAQ Board

• Contains 9 FPGA’s

•

Includes Command Response Unit, Fan-out and fanin of commanding to 16 TEMs, PDU, EPU’s,

ACD

• Includes Global Trigger Logic

• Includes LAT Event-Builder Logic

•

Includes command/control/read-back for ACD sub-system

• Includes power-control for ACD FREE Boards

DOE Review, February 18, 2005

PDU enclosure with primary/redundant PDU circuit cards, no coating/staking

4.1.7 DAQ & FSW V1 10

GLAST LAT Project DOE Review, February 18, 2005

GASU Status and Schedule

• Status

– Design/documentation complete

– Enclosures fabricated

– All components/parts received

– Assembly contract awarded

– Parts being kitted

– Flight assembly to start 3/10/05

• Schedule for Flight Unit

– 5/20/05 Precoat GASU assembly ready for electrical test

– 6/10/05 Complete assembly ready for environmental test

– 7/13/05 Flight GASU to I&T

4.1.7 DAQ & FSW V1 11

GLAST LAT Project

SIU/EPU

• Spacecraft Interface Unit (SIU)

• Event Processor Unit (EPU)

• Difference is boot code loaded into RAD750 CPU

LCB Enclosure

Power-Supply

DOE Review, February 18, 2005

Backplane

CPU

SIB

4.1.7 DAQ & FSW V1 12

GLAST LAT Project DOE Review, February 18, 2005

SIU/EPU Status and Schedule

• Status

– Design/documentation complete

– Enclosures fabricated

– All components/parts received except BAE RAD750 CPU

• Uses recalled International Rectifier regulator

• Boards to be sent back to BAE

• Reworked boards expected 3 weeks after they receive components; June 05

– Assembly contract out for RFP

•

Schedule

– 6/1/05 Precoat cCPI boards ready for electrical test

– 7/28/05 Complete assembly ready for environmental test

– 8/19/05 First Flight SIU/EPU to I&T

– 8/24/05 Second flight SIU/EPU to I&T

– 8/27/05 Third flight SIU/EPU to I&T

– 8/30/05 Fourth flight SIU/EPU to I&T

– 9/2/05 Last flight SIU/EPU to I&T

4.1.7 DAQ & FSW V1 13

GLAST LAT Project DOE Review, February 18, 2005

Testbed and I&T Support

• Testbed

– Upgrade of engineering modules to reflect flight designs

– Scheduled over next 6 months

– Labor to support upgrade

– Labor to support testing of electronics and flight software using data generated via front-end simulator boards

– Labor to support test-stands for flight electronics qualification and acceptance testing

• I&T Support

– Design/fabrication/testing of virtual spacecraft simulator for

I&T

– Support for integration and testing of DAQ modules on instrument

4.1.7 DAQ & FSW V1 14

GLAST LAT Project DOE Review, February 18, 2005

Management & EGSE

• Management

– Sub-system manager

– Technical writer

– Support for environmental test

– Travel

– Computer for test-stations (HW & SW) maintenance

– Shipping charges for flight hardware

• EGSE (Electrical Ground Support Equipment)

– Maintenance/repair of test-stations supplied to sub-systems

4.1.7 DAQ & FSW V1 15

GLAST LAT Project

Costs & Commits

DOE Review, February 18, 2005

4.1.7 DAQ & FSW V1

Explanation:

Dataflow Electronics = TEM/TPS Flight Units

ACD GASU FU & GLT FU = GASU

Power Conditioning = PDU

SIU & LAT Communication Card = SIU

16