WW_Mon_AM_10.25_Stinson

advertisement

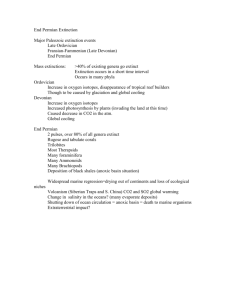

Roadmap Toward Sustainable Nutrient Management The Role of Mainstream Deammonification Presented by: Beverley Stinson, Ph.D Global Wastewater Practice Leader, AECOM Acknowledgements: Sudhir Murthy, Ahmed Al-Omari & Haydee De Clippeleir DC Water Charles Bott HRSD Bernhard Wett, Ph.D ARA Consult Gregory Bowden AECOM THE TEAM Ahmed Al-Omari Olawale Akintayo Charles Bott Ryder Bunce Kartik Chandran Michael Desta Norman Dockett Haydee De Clippeleir Dana Fredericks Gomez Brandon Mofei Han Martin Hell Becky Holgate Rebecca Jimenez Jose Jimenez David Kinnear Hansa Keswani Yi Wei Ma Matthew Michaelis Mark Miller Geert Nyhuis Sylvia Okogi Maureen O’Shaughnessy Hong Keun Park Sabine Podmirseg Pusker Regmi Rumana Riffat Andrew Shaw Beverley Stinson Imre Takacs Claire Welling Bernhard Wett Agenda: 01 Drivers & Challenges for Mainstream Deammonification 02 “Recipe” for Success • • Mechanisms & Control Strategies Potential Engineering Implementation Concepts 03 “Proof of the Pudding” – Full Scale Mainstream Deammonification Demonstrations Drivers & Challenges Eutrophication due to excessive nutrient discharge is a global problem • Fundamentally impacting issues such as: – – – – – Water security Public health Economic and community growth Tourism Environmental aesthetics and quality of life While the environmental, social and economic benefits of nutrient management are extensive, they come at a price…. • • Conventional Biological Nutrient Removal (BNR) processes rely on anaerobic, anoxic and aerobic microbes to remove N&P from wastewater Nutrient Management at Wastewater Treatment Plants results in increased: – Energy demand Activated-sludge – Chemical demand Aeration 55.6% – Space – Carbon footprint – Greenhouse gas emissions. • Increased Capital & Operating Costs & Complexity Conventional BNR processes require significant aeration energy typically accounting for half the electrical demand at a plant. Distribution of Energy Usage for a Typical BNR WWTP Lighting & Misc. 2% UV Disinfection 4% Chlorination 0% Centrifuge 8% Belt Filter Press 1% Pumping & Screening 7% Aerated Grit Removal 1% Primary Clarifiers 1% Anaerobic Digestion 9% Gravity Belt Thickener 1% Dissolved Air Flotation 7% Gravity Thickening Activated-sludge 0% Aeration 55.6% Filtration 2% Aeration 48% Filter Feed Pumping 4% Chemical Addition 2% Secondary Clarifiers 1% RAS Pumping 2% 400 MLD (105 mgd) Nitrifying Activated Sludge Facility Fundamentals of Nitrification - Denitrification Heterotrophic Denitrification Autotrophic Nitrification 1 mol Nitrate (NO3- ) Aerobic Environment Anoxic Environment 40% Carbon 25% O2 1 mol Nitrite (NO2- ) 1 mol Nitrite (NO2- ) 60% Carbon 75% O2 100% Alkalinity 1 mol Ammonia (NH3/ NH4 +) ½ mol Nitrogen Gas (N2 ) + Oxygen demand 4.57 g / g NH 4-N oxidized Carbon demand 4.77 g COD / g NO-3-N reduced The Road to Sustainable and Efficient Nitrogen Management 1. 2. 3. – Maximize carbon capture – Maximize energy recovery – Minimize carbon & energy demand for N & P removal A-Stage Biosolids B-Stage 3 1 2 3 Fundamentals of Nitritation - Denitritation Autotrophic Nitritation Heterotrophic Denitrification 1 mol Nitrate (NO3- ) Aerobic Environment 25% O2 Anoxic Environment 40% Carbon • 25% reduction in Oxygen • 40 % reduction in Carbon demand • 40% reduction in Biomass production 1 mol Nitrite (NO2- ) 1 mol Nitrite (NO2- ) 60% Carbon 75% O2 100% Alkalinity 1 mol Ammonia (NH3/ NH4 +) ½ mol Nitrogen Gas (N2 ) Oxygen demand 3.42 g / g NH+4-N oxidized Carbon demand 2.86 g COD / g NO-3-N reduced Fundamentals of Deammonification Partial Nitritation Aerobic Environment 1 mol Nitrate (NO3- ) ANAMMOX Deammonification Anaerobic Ammonium Oxidation Autotrophic Nitrite Reduction 40% Carbon Strous et. al. 1999) (New Planctomycete, • > 60% reduction in Oxygen NH4+ + 1.32 NO2- + 0.066 HCO3- + 0.13 H+ • Eliminate demand for supplemental carbon 0.26 NO3- + 1.02N2 + 0.066 CH2O0.5N0.15 + 2.03 H2O 25% O2 • 50% of the alkalinity demand 0.57 mol NO2- Partial Nitritation 40% O2 50% Alkalinity 1 mol Ammonia (NH3/ NH4 +) 0.44 mol N2+ 0.11 NO3Oxygen demand 1.9 g / g NH+4-N oxidized Overall Benefit of Deammonification Processes • • Eliminates need for carbon for TN removal making it available for energy recovery Significant reduction in energy demand possible Reduction in alkalinity demand Typical Energy Demand Ranges 7 6 kW-hr / kg N removed • 5 4 3 2 1 0 Nitrification / Denitrification Nitritation / Denitritation Deammonification (a.k.a. ANAMMOX) Challenges of the Anammox Organism • Low Growth Rate approx. 10 day doubling time at 30C <10 day has been reported (Park et. al - 5.3 - 8.9 days) SRT (>30 days) • Sensitive to; Nitrite ‒ Toxic- irreversible loss of activity based on concentration & exposure time ‒ NH4+ : NO2- ratio 1 : 1.32 • DO - reversible inhibition • Free ammonia (<10 -15 mg/l) • Temperature >30C preferred • pH (neutral range) Centrate / Filtrate Characteristics PST Activated Sludge Effluent RAS Reduce Effluent TN by ≈ 20% WAS Thickening Digestion / CHP Sidestream Deammonification Centrate • 1% Plant Influent Flow • Rich in Nitrogen & Phosphorus • 15 to 25% Plant Influent TN load • Ammonium Conc. 800 to 2,500 mg-N/L • Centrate TP = 200-800 mg/L • Temperature 30 - 38C • Alkalinity insufficient for complete nitrification • Insufficient carbon for denitrification Dewatering Beneficial Reuse of Biosolids Sidestream Nitritation – NOB Repression • Control – Elevated NH3-N concentrations – Elevated temperature (30-35 deg C) – Low SRT (1-2 days) – Low DO (~0.5 mg/L) • NOB Repression Mechanisms – Free NH4 –N inhibition of NOB > AOB – Nitrous acid inhibition of NOB > AOB – AOB max growth rate > NOB max growth rate at high temp – AOB DO affinity > NOB DO affinity (perhaps only at high temp) Sidestream Deammonifcation Operational Experience • DEMON® Suspended Growth SBR – 15 Operational /11 in Construction – York River, VA, Alexandria, VA, Blue Plains, DC • Cleargreen® Suspended Growth SBR – 3 Pilots / 3 WWTPs in Design • Terra-N Hybrid Suspended and Attached – 4 Operational Facilities (Germany) • DEMON®, Cleargreen, Terra-N Anita®MOX Attached Growth MBBR – 4 Operational / 2 Start-up – James River, VA & South Durham, NC • ANAMMOX® Upflow Granular – 11 Operational facilities (4 WWTPs / 7 industrial) – 9 in Design / Construction (2 WWTPs / 7 Industrial)ANITATM MOx MBBR ANAMMOX® Upflow Granular Process Sidestream Deammonification - Proven Technology ANAMMOX DEMON MBBR AnitaMox First Demonstration Final Generation Mature Technology Second Generation (building on lessons learned from first applications) Terra-N Pilot IFAS AnitaMox Clear Green First Applications Operational Cost Savings $8.5M / yr (methanol, alkalinity, sludge processing 9 year payback Risk Mitigation for effluent TN Sidestream Treatment 20,200 lbs /day NH3-N Mainstream Treatment 105,000 lbs/day TKN Energy Positive Plants feasible with a combination of Sidestream and Mainstream Deammonification Coupled with Efficient Carbon Capture & Energy Recovery 129% energy positive • Specific growth rate (1/d) 1 AOB Challenges for Mainstream Deammonification 0.8 vs. Sidestream Deammonification 0.6 NOB 0.4 Lower influent & effluent nitrogen concentrations 0.2acid inhibition of NOB – Lack of free ammonia & low nitrous 0 to outcompete the NOB at lower N – Reduced competitiveness of the AOB 0 1 2 3 concentrations Dissolved Oxygen, mg/L • Lower and more variable operating 1temperatures Specific growth rate (1/d) AOB – Slow growth rate of the Anammox 0.8 – Relative growth rates of NOB > AOB at Temperatures < 15-17°C • 4 0.6 NOB Higher carbon to nitrogen ratios - OHO will compete with; 0.4 – AOB for oxygen under aerobic conditions 0.2 – anammox for the nitrite under anoxic conditions. 0 – anammox for organic substrate (certain 0 anammox 1 can denitrify 2 using organic 3 4 acids (Kartal et al. 2007). Ammonia (AOB) or nitrite (NOB), mg-N/L Zone 3 complete nitrification Anthonisen et al. 1976 Chandran & Smets, 2005 Approaches to Mainstream Nitrite Shunt / Deammonification Small Flocculant &Suspended Growth Anammox Granules e.g. Activated Sludge Systems • • • • • • • • Large Anammox Granules e.g. granular sludge systems Hybrid Suspended & Attached Growth e.g. IFAS Increasing diffusivity or mass transfer resistance • Delft Technical DC Water, USA University / Paques / HRSD, USA WSHD – Dokhaven, AIZ Strass/ARA Consult, Austria Netherlands Glarnarland/Cyklar-Stulz, Austria Changi WRP, Singapore PUB Bejing Technical University, China Beijing Drainage Group, China Harbin IT, China • Veolia Water, France Attached Growth Biofilm e.g. RBC, MBBR, Biofilter • Ghent University RBC • Veolia Water, France WERF Mainstream Deammonification Project 3 different sites and scales DC Water WWTP Strass HRSD Recipe for Success Do’s and Don’t’s of Mainstream Deammonification 1. 2. 1 mol Nitrate (NO3- ) AOB Growth & Retention Anammox Growth & Retention Ordinary 0.57 mol NO2- Heterotrophs (OHO) 40% Carbon 1 mol Nitrite (NO2- ) 60% Carbon 3. Control OHO Activity AnAOB / Anammox 4. Limit NOB Growth 1 mol Ammonia (NH3/ NH4 +) 0.44 mol N2+ 0.11 NO3- Do’s and Don’t’s of Mainstream Deammonification 1. 2. AOB Growth & Retention – – – Bioaugmentation NH3-N concentrations > 2 Dissolved Oxygen > 2 AnAOB / Anammox Anammox Growth & Retention – – Bioaugmentation Cyclones, Sieves 3. Control OHO Activity 4. 0.57 mol NO2- Limit NOB Growth 1 mol Ammonia (NH3/ NH4 +) 0.44 mol N2+ 0.11 NO3- Bioaugment mainstream with AOB & anammox from sidestream “incubator” Bioaugmentation of AOB and Anammox from Side Stream Filtrate Deammonification Facility Post Anoxic Polishing Convert “B” stage to mainstream deammonification Anammox Retention in Mainstream Viable Mechanisms Under Investigation: 1. 2. 3. 4. 5. Cyclones Sieves Membranes Granules Biofilms • MBBR • RBC - Strass & Glarnarland - Blue Plains - Singapore PUB, American Water - Delft TU / Paques - Veolia, HRSD - Ghent University Commonly accepted that growth rate and affinity for oxygen AOB > NOBs • Conventional Wisdom based on pure cultures of Nitrobacter Bench Scale Testing - Cyclical DO Operational Scenarios Low/Constant DO Low DO/Intermittent aeration High DO/Intermittent aeration Intermittent Low DO Aeration “N Profiles” Still significant NOB activity In our experience, at low DO, Growth Rate & Affinity for Oxygen of NOB > AOB Mixed culture of NOB with Nitrospira more dominant than Nitrobacter Possibly Nitrospira & other NOB species Bench Scale Testing - Cyclical DO Operational Scenarios Low/Constant DO Low DO/Intermittent aeration High DO/Intermittent aeration Intermittent High DO Aeration “N Profiles” Almost no NOB Activity Stochiometric NO3-N production (11% as NO3-N) Specific growth r (1/d) 0.8 NOB 0.6 For Optimal AOB Growth 0.4 Maintain Higher NH3-N concentrations Maintain NH3-N >2 mg/l NOB are able0to compete effectively with AOB for oxygen at low NH3-N 1 2 3 4 concentrations 0 Dissolved Oxygen, mg/L 1 Specific growth rate (1/d) • • 0.2 AOB 0.8 NOB 0.6 0.4 0.2 0 0 1 2 3 Ammonia (AOB) or nitrite (NOB), mg-N/L Chandran and Smets (2005) Water Research, 39, 4969 4 Intermittent High DO Aeration Low Ammonia Without Residual Ammonia Low Ammonia Residual NOB begin to Thrive Do’s and Don’t’s of Mainstream Deammonification 1. AOB Growth & Retention – – – 2. Anammox Growth & Retention – – 1 mol Nitrate (NO3- ) Bioaugmentation NH3-N concentrations > 2 Dissolved Oxygen > 2 0.57 mol NO2- Ordinary Heterotrophs (OHO) 40% Carbon 1 mol Nitrite (NO2- ) 60% Carbon Bioaugmentation Cyclones, Sieves AnAOB / Anammox 3. Control OHO Activity 4. Limit NOB Growth 1 mol Ammonia (NH3/ NH4 +) 0.44 mol N2+ 0.11 NO3- The Road to Sustainable and Efficient Nitrogen Management 1. 2. 3. A-Stage Biosolids B-Stage 1 – Maximize carbon capture – Maximize energy recovery – Minimize carbon & energy demand for N & P removal 3. Control OHO Activity – CEPT & HRAS Adsorption • C:N ratio may be a key control factor in defining predominant pathway for TN removal Higher C:N ratio Medium C:N 6 - 10 :1 range? 3 - 5 :1 range? Anammox Outcompete OHO OHO Outcompete Anammox Conventional Nitrification / Denitrification Lower C:N ratio 1 - 3 :1 range ? Nitrite Shunt Deammonification 3. Control OHO Activity – CEPT & HRAS Adsorption 1 & 2. New Side Stream Filtrate Deammonification Facility “AOB & Anammox growth” 3. HRAS “A” stage Adsorption of colloidal sCOD Carbon to Digesters/ CHP Expansion 2. Convert “B” stage to mainstream deammonification 3. CEPT Carbon to Digesters/ CHP 4. Mechanisms for NOB Repression a) Competition - Outselection – Aerobic conditions - AOB & OHO compete with NOB for O2 • Maintain maximum AOB rates by: – Bioaugmentation – Optimal conditions (NH3-N >2 and DO >1.5) – Anoxic conditions – anammox & OHO compete with NOB for nitrite • Bioaugmentation and retention of anammox b) Inhibition of NOB – – – – Hydroxylamine ? Hydrazine ? Nitric Oxide ? Formic acid ? NOB Repression / Inhibition Opportunities Inhibitors/conditions Literature Mainstream Conditions (mg N/L) (mg N/L) (mg N/L) Free ammonia (NH4+) 0.04 - 0.08 0.005 - 0.1 0.2 - 0.4 (centrate contact) Free nitrous acid (HNO2) 0.01-0.8 <0.001 (Max of 5 mg NO2-N/L present) Hydroxylamine (NH2OH) 0.2 Intermediate of AOBs. Under evaluation may hold promise Hydrazine (N2H4) 1.0 (Only for Nitrobacter) 0.1 Produced by Brocadia Anammoxidans Nitric Oxide (NO) 0.007-0.448 Depends on nitrite accumulation. Reversible NOB inhibition but also stimulates anammox growth Formic Acid (HCOOH) >100mg/l complete inhibition – no adverse effect on AerAOBs Used for fine bubble diffuser cleaning so infrastructure may already exist. Salinity >5 Aeration duration control DO > 2 mg/l Using real time pH, DO and ORP control and / or Blower Frequency Transient anoxia Low DO Not effective Transient anoxia High DO Very Effective 4. Mechanisms for NOB Repression c) Transient Anoxia – – – – – Lag in nitrite availability for NOB once aeration begins Intermittent aeration Deplete DO quickly – avoid sustained low DO high nitrite conditions Step-feed COD to anoxic zones CEPT by-pass for extra solCOD as needed - Oxygen - Nitrite lag Reactor modifications • • • Sequential aerobic anoxic zones for transient anoxia “in space” Transient anoxia “in time” with air cycling on & off also effective Step-feed to deliver COD to anoxic zones for DO depletion 1. Baffles in stages 2&4 2. Use aeration grids in aerobic zones and mixers in anoxic zones 3. Motor actuated butterfly valves and air flow meters for process air 4. Add feed channels & gates to anoxic zones 2b, 3b 5. CEPT by-pass 6. NH3-N and NOx-N probes for process control (e.g. AVN controller by HRSD) Mainstream Deammonification Implementation Strategy for Blue Plains 3. HRAS “A” stage Adsorption of colloidal & sCOD. Carbon to Digesters/ CHP Post Anoxic or Anammox Polishing 1. & 2. Bioaugmentation of AOB and Anammox from Side Stream Filtrate Deammonification Facility Step-feed tanks with sequential aerobic anoxic zones & swing zones for post aerobic polishing Cyclones for anammox retention 3. CEPT Particulate Carbon to Digesters/ CHP Recipe for Mainstream Deammonification • AOB & Anammox Bioaugmentation from sidestream • Anammox Retention in Mainstream • Intermittent high DO “transient anoxia” – At high DO AOB grow faster than NOB – NOB seem to have a delayed response as they move from anoxic to aerobic zones • Maintain residual ammonia > 2 mg/l – Ensure max ammonia oxidation rates so AOB outcompete NOB for DO – Ammonia based aeration control (AVN controller by HRSD) • Rapid transition to anoxia – DO must be scavenged quickly to avoid a “low” DO environment – Step-feed to anoxic zones to deplete DO quickly – CEPT by-pass to enhance soluble COD as needed • Aggressive SRT Control – Lower SRT results in selective washout of NOB at warmer temperatures Recipe for Mainstream Deammonification • Final Polishing Step to reduce: – Residual ammonia – Residual nitrate to nitrite • Can use one of two techniques – Polishing aerobic & anoxic zone to fully nitrify remaining NH4-N and denitrify with supplemental carbon – Use Brocadia Anammoxidans or Methyloversatilis Mainstream Deammonification Implementation Strategy for Blue Plains 3. HRAS “A” stage Adsorption of colloidal & sCOD. Carbon to Digesters/ CHP 1. & 2. Bioaugmentation of AOB and Anammox from Side Stream Filtrate Deammonification Facility Step-feed tanks with sequential aerobic anoxic zones & swing zones for post aerobic polishing Cyclones for anammox retention 4. Post Anoxic or Post Anammox Polishing 3. CEPT Particulate Carbon to Digesters/ CHP Single point carbon addition Proof of the Pudding Changi Water Reclamation Plant (WRP) Warm Climate Full Scale Mainstream Deammonification Demonstration • • • • • • • Full scale demonstration was based upon successful strategies proven at pilot scale Changi - largest WRP in Singapore: 800 000 m3/day. Tropical climate: sewage temperature between 28-32 °C Five basins with cyclical anoxic/ aerobic zones. Feeding: 20% of primary effluent to each anoxic zone Total SRT: 5 days with 2.5 day SRT for aerobic and anoxic HRT: 5.7 hours Changi’s Positive Performance Provided Proof of Concept 144 m Basin 6 (Of f line) Zone 4 Anoxic • Observe significant portion of the ammonia converted to nitrite as opposed to nitrate indicating robust NOB suppression • Observe concomitant reduction in ammonia & nitrite in anoxic zones indicating reliable anammox activity • Full scale demonstration of mainstream deammonification Basin 1 Zone 4 Anoxic Aerobic Zone Basin 2 Zone 4 Anoxic Aerobic Zone Basin 3 Zone 4 Anoxic Aerobic Zone Basin 4 Zone 4 Anoxic Aerobic Zone Basin 5 Zone 4 Anoxic Aerobic Zone Aerobic Zone Zone 3 Anoxic Zone 3 Anoxic Zone 3 Anoxic Zone 3 Anoxic Zone 3 Anoxic Zone 3 Anoxic Zone 2 Anoxic Zone 2 Anoxic Zone 2 Anoxic Zone 2 Anoxic Zone 2 Anoxic Zone 2 Anoxic Zone 1 Anoxic Zone 1 Anoxic Zone 1 Anoxic Zone 1 Anoxic Zone 1 Anoxic Zone 1 Anoxic 50 m RAS To SST PE Basin 6 under maintenance Inlet of anoxic zone Sampling Point Ammonia Nitrite Nitrate Strass WWTP, Austria, Full Scale Demonstration • • • • • • A-B type plant – ½ day SRT A-Stage followed by B-Stage - >65% COD removed in HRAS Sidestream DEMON - AOB & anammox Bio-Aug Cyclones - mainstream anammox retention Ammonia based aeration control - NH3-N >2 mg/l Carousel type aeration tank providing high DO transient anoxia (DO 0 - 1.7 mg/L). Heavily loaded during winter ski season – Temp 10-12°C range – Nitrite shunt / deammonification observed nitrogen N/L) (mgN/L) concentration(mg nitrogenconcentration Full Scale Success with Mainstream Nitrite Shunt / Deammonification 25 2010/2011NO3-N NO3-N effluent effluent 2010/2011 2010/2011 NO2-N NO2-N effluent 2010/2011 effluent 20 2011/2012 NO3-N 2011/2012 NO3-Neffluent effluent 2011/2012 NO2-N 2011/2012 NO2-Neffluent effluent Conventional MLE BNR 2010 15 Mainstream nitrite Shunt / Deammonification 2011 10 5 0 1-Dec 1-Dec 11-Dec 31-Dec 21-Dec 30-Jan 31-Dec 29-Feb 10-Jan 30-Mar 20-Jan 29-Apr 30-Jan 29-May Conclusions • Nitrite Shunt / Mainstream Deammonification strategy promising • Demonstrated successfully at full scale – Strass, Austria – Changi, Singapore PUB (cold with bioaugmentation) (warm without bioaugmentation) • Based upon an evaluation of eight other plants, it seems reasonably feasible to retrofit into an existing activated sludge system • When upgrading, consider incorporating flexibility for future implementation Bev Stinson Beverley.Stinson@aecom.com