Material Requirements Planning Defined

advertisement

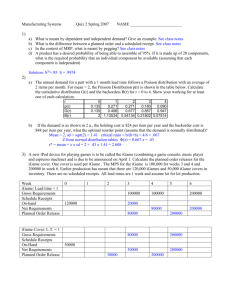

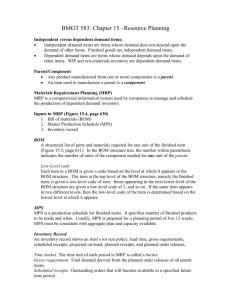

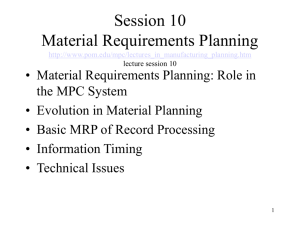

Material Requirements Planning Defined • Materials requirements planning (MRP) is the logic for determining the number of parts, components, and materials needed to produce a product. • MRP provides time scheduling information specifying when each of the materials, parts, and components should be ordered or produced. • Dependent demand drives MRP. Material Requirements Planning System • Based on a master production schedule, a material requirements planning system: – Creates schedules identifying the specific parts and materials required to produce end items. – Determines exact unit numbers needed. – Determines the dates when orders for those materials should be released, based on lead times. 3 Firm orders from known customers Aggregate product plan Forecasts of demand from random customers Engineering design changes Master production schedule (MPS) Inventory transactions Bill of material file Material planning (MRP) Inventory record file Reports Product Structure Thinking Challenge The demand for product A is 50. How many of each component is needed to satisfy demand? A B(2) C(3) E(3) D(2) E(1) F(2) G(1) D(2) Product Structure Solution A 50 50 x 2 = 100 50 x 3 = 150 B(2) C(3) E(3) D(2) 100 x 2 = 200 100 x 3 = 300 150 x 2 = F(2) 300 E(1) 150 x 1 = 150 G(1) Note: D: 200 + 600 = 800 E: 300 + 150 = 450 300 x 1 = 300 D(2) 300 x 2 = 600 MRP Scheduling Terminology • Net requirements – the amount needed to meet gross requirements in a particular period. • Planned order receipt - amount of the item that you are planning to receive in a particular period • Planned order release - an order that you are planning to release in a particular period MRP Example - One item’s complete record Starting information 1 2 Gross Requirements 2 20 Scheduled Receipts 5 On-Hand 20 3 4 5 25 15 30 20 Net Requirements Planned Order Receipts Planned Order Releases Lead time = 3; lot policy = lot-for-lot (LFL); on-hand = 20 units; safety stock = 0 units. MRP Example - Period 1 1 2 Gross Requirements 2 20 Scheduled Receipts 5 On-Hand 20 20 3 4 5 25 15 30 23 Net Requirements Planned Order Receipts Planned Order Releases Lead time = 3; lot policy = lot-for-lot (LFL); on-hand = 20 units; safety stock = 0 units. MRP Example - Period 2 1 2 Gross Requirements 2 20 Scheduled Receipts 5 On-Hand 20 20 3 4 5 25 15 30 23 3 Net Requirements Planned Order Receipts Planned Order Releases Lead time = 3; lot policy = lot-for-lot (LFL); on-hand = 20 units; safety stock = 0 units. MRP Example - Period 3 1 2 Gross Requirements 2 20 Scheduled Receipts 5 On-Hand 20 20 3 4 5 25 15 30 23 3 33 Net Requirements Planned Order Receipts Planned Order Releases Lead time = 3; lot policy = lot-for-lot (LFL); on-hand = 20 units; safety stock = 0 units. MRP Example - Period 4 1 2 Gross Requirements 2 20 Scheduled Receipts 5 On-Hand 20 20 3 4 5 25 15 33 8 30 23 3 Net Requirements Planned Order Receipts Planned Order Releases Lead time = 3; lot policy = lot-for-lot (LFL); on-hand = 20 units; safety stock = 0 units. MRP Example - Period 5 1 2 Gross Requirements 2 20 Scheduled Receipts 5 On-Hand 20 20 3 4 5 25 15 33 8 30 23 3 Net Requirements 7 Planned Order Receipts 7 Planned Order Releases 7 Lead time = 3; lot policy = lot-for-lot (LFL); on-hand = 20 units; safety stock = 0 units. Low Level Coding Won’t having the • What about this? A Level 0 Level 2 Level 3 C B Level 1 D C E E same part at different levels make it harder to do level by level calculations? Low Level Coding - “How to” • Place each item at same level - it simplifies the calculations Before: After: A A Level 0 Level 2 Level 3 C B Level 1 D C E E B D C C E E Another MRP Example An end item (A) is assembled from 1 sub-component C, 2 part D’s, and 1 sub-component B Each sub-component C is assembled from 1 part D and 1 part E Each sub-component B is assembled from 1 part C and 2 part E’s The master production schedule calls for 250 units of A in week 6, 140 in week 8, and 200 in week 9. The following information is available from the inventory status file: Part/Sub-component A B C D E Beginning Available 5 5 0 0 5 Scheduled Receipts 0 0 0 5 in week 1 5 in week 2 Lead Time Safety Stock 1 week 0 1 week 5 2 weeks 0 1 week 0 1 week 0 Lot Size L4L 10's L4L 150 min. 10's Types of Time Fences • Frozen – No schedule changes allowed within this window. • Moderately Firm – Specific changes allowed within product groups as long as parts are available. • Flexible – Significant variation allowed as long as overall capacity requirements remain at the same levels. Example of Time Fences Moderately Firm Frozen Flexible Capacity Forecast and available capacity Firm Customer Orders 8 15 Weeks 26 Work-Center Scheduling Objectives • Meet due dates • Minimize lead time • Minimize setup time or cost • Minimize work-in-process inventory • Maximize machine utilization Priority Rules for Job Sequencing 1. First-come, first-served (FCFS) 2. Shortest operating time (SOT) 3. Last-come, first served (LCFS) 4. Earliest due date first (EDD) Many other possible rules... Example of Job Sequencing: First-Come First-Served Suppose you have the four jobs to the right arrive for processing on one machine. What is the FCFS schedule? Jobs (in order of arrival) A B C D Processing Due Date Time (days) (days hence) 4 5 7 10 3 6 1 4 Average Lateness = (0 +1 + 8 + 11)/4 Answer: FCFS Schedule Jobs (in order of arrival) A B C D Processing Time (days) 4 7 3 1 Due Date Flow Time (days hence) (days) 5 4 10 11 6 14 4 15 = 5 days Late 0 1 8 11 Average Flow Time = (4+11+14+15)/4 = 11 days Total Flow Time Summary: Priority Rule FCFS SOT LCFS EDD Average Flow Time 11 days 7 days 7.75 days 7.25 days Average Lateness 5 days 2 days 2.75 days 1.75 days Total Flow Time 15 15 15 15 Characteristics of Location Decisions • • • Long-term decisions Very difficult to reverse Affect fixed & variable costs – Transportation cost • As much as 25% of product price – Other costs: Taxes, wages, rent etc. • Objective: Maximize benefit of location to firm Manufacturing Location Strategies • Cost focus – Revenue varies little between locations • Location is a major cost factor – Affects shipping & production costs (e.g., labor) – Costs vary greatly between locations © 1995 Corel Corp. Service Location Strategies • Revenue focus – Costs differences among locations are relatively less important • Location is a major revenue factor – Affects amount of customer contact – Affects volume of business © 1995 Corel Corp. Location Methods: Factor Rating Method • • • Most widely used location technique Useful for service & manufacturing locations Rates locations using factors – Qualitative (intangible) factors • Example: Education quality, labor skills – Quantitative (tangible) factors • Example: Short-run & long-run costs Factor Rating Method Solution Factor Weight Score Mfg. costs 0.7 8 Cost of living 0.1 7 Labor avail. 0.2 10 1 Omaha is best Omaha Denver Weighted Weighted Factor Score Factor 5.6 6 4.2 0.7 6 0.6 2 8 1.6 8.3 6.4 Location Methods: Factor Rating Method +/+ Easy to understand and compute - How do you pick weights? - How do you assign rankings? Location Decision Sequence 1. Country 2. Region/Community 3. Site © 1995 Corel Corp. © 1995 Corel Corp. © 1995 Corel Corp. Plant Location Methodology: Centroid Method Formulas Cx = d V V ix i Cy = i d V V iy i i Cx = X coordinate of the centroid Cy = Y coordinate of the centroid dix = X coordinate of the ith location diy = Y coordinate of the ith location Vi = volume of goods moved to or from ith location Plant Location Methodology: Example of Centroid Method • Centroid method example – Several automobile showrooms are located according to the following grid which represents coordinate locations for each showroom. S ho wro o m Y Q No o f Z-Mo b ile s s o ld p e r mo nth (790,900) D A 1250 D 1900 Q 2300 (250,580) A (100,200) (0,0) X Question: What is the best location for a new Z-Mobile warehouse/temporary storage facility considering only distances and quantities sold per month? Thinking Challenge Solution Warehouse at (77, 57): Wenatchee Nat’l Forest! Seattle (50,60) 494k units 90 60 X 30 Aberdeen (20,35) 18k units Spokane (160,50) 171k units 0 © 1995 Corel Corp. 0 30 60 90 120 150 Balancing Supply Chain Capability with Customer Demands Increased Demand: Marketing programs Promotions Customer Requirements Supply Chain Capability Customer Requirements Supply Chain Capability Suppliers, Manufacturers, Distributors, Carriers Market Demand,New Products, Promotions Increased Costs Overtime Expediting Increased Inventory Information Information Internal Supply-Chain Performance • Inventory Turnover = Cost of goods sold Average inventory value . Average Inventory Value Weeks of Supply (52 Weeks) Cost of Goods Sold Supply Chain Measures Common practice is to measure within a function: Supplier Price Plant Cost Efficiency Output Distribution Customer Center Inventory Stock Rotation Space Cost Quality Speed Flexibility Measure Across Supply Chain Nodes The correct method is to measure across a node: Supplier Plant Cycle Time On-time Delivery Vendor Managed Inventory Distribution Center Cycle Time Delivery Reliability Product Availability Customer Cycle Time Order Completion Performance The Bullwhip Effect – Cont’d What is Outsourcing? Defined Outsourcing: moving a firm’s internal activities and decision responsibility to outside providers. Reasons to Outsource • Organizationally-driven - gain focus • Improvement-driven - quality, skills, innovation • Financially-driven - reduce asset investment • Revenue-driven - gain market access, expand sales • Cost-driven - supplier has lower cost structure