Unit 2 Manufacturing Materials

advertisement

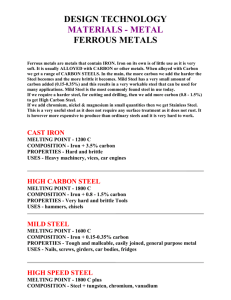

Unit 2 Manufacturing Materials Ch 3-5 R. Thomas Wright Manufacturing • Changes resources into more useful products. – Hardware – Wood products – Metal products – Plastics – Glass – Ceramic – Medicine Materials Used in Manufacturing • Are derived from two sources – Organic Materials: Traced back to living things • Coal, Petroleum, and Wood – Inorganic Materials: Non-living Ores and earth elements • Copper, Gold, Aluminum, Glass, Cement, and Rock Three States of Organic and Inorganic Materials • Gases, Liquids, and Solids • Non-Engineering Materials: are gases and liquids that must be confined in a container to hold shape. • Engineering Materials: are solid materials that will hold their shape without outside support. – Engineering Materials are divided into four categories: • • • • Metallic Materials Polymeric Materials Ceramic Materials Composite Materials (Newest Form) Metallic Materials • Inorganic, crystalline substances with a wide range of physical and mechanical properties. • Pure metals are usually not used in their raw state. They are converted • Alloy: Mixture of two or more metals or inorganic materials. – Brass = copper + zinc Metallic Materials Ferrous Metals • Ferrous Metals are derived from iron and are composed of more than 90% iron and less than 10% induced carbon • All ferrous metals are technically termed as Iron Carbon Alloys • Steel is grouped into two categories – Carbon Steel – High Alloy Steel Metallic Materials Ferrous Metals – Carbon Steel • Carbon Steel: Most common form of steel where carbon is the major alloying element – Can have up to 1% Carbon (C) – No more than 1.65% Manganese (Mn) – .60% Silicon (Si) – .60% Copper (Cu) Metallic Materials Ferrous Metals – Carbon Steel-Classification • Carbon steel is classified by a numbering system and then divided into a specific class • American Iron and Steel Institute (AISI) numbering system (4 Digit System): – AISI 1030 = • 1 (1st digit) = Carbon (C) Steel • 30 (Last 2 digits) = carbon (C) content in points or 1/100% – 30 x .01 = .30% carbon (C) Metallic Materials Ferrous Metals – Carbon Steel-Classification • • • • AISI 1030 = .30% carbon (C) content .30% (C) and ↓ = Low Carbon Steel .30% (C) to .55% (C) = Medium Carbon Steel .55% (C) ↑ = High Carbon Steel Metallic Materials Ferrous Metals – High Alloy Steel • High Alloy Steels: Special steels alloyed with molybdenum, nickel, tungsten, or other elements. (Tool steel or high speed steel) – High-Speed or Tool Steel: generic name applied to all steels that hold their sharpness under high heat. Molybdenum, and tungsten resist the heat. – Stainless Steel: Iron-carbon-chromium-nickel alloyed steel. Chromium oxide on the surface level that resists corrosion. Metallic Materials Non-Ferrous Metals • Non-Ferrous: Metals that do not have iron as the main ingredient. – Aluminum: Bauxite ore converted into aluminum oxide. • 99.3% pure and lightweight – Copper: 99.9% pure • Brass = Copper and Zinc alloy • Bronze = Copper-Tin or Copper-Aluminum • Nickel Silver = Copper is 70% ingredient – Lead: Heavy and soft metal • Toxic!!!! Microstructure • Microstructure: The way molecules and crystals are arranged in a material. Must be viewed under a microscope because the structure is so small – Determines what a material is Properties • Properties are traits or qualities that are specific to a material. –Determines what materials will be used for Physical Properties • Physical Properties: Characteristics that describe the size, density, or surface texture of a product. • What one will see when they look at this material Mechanical Properties • Mechanical Properties: Characteristics that govern how a material will react to force or load. – Compression – Tension – Shear – Torsion Chemical Properties • Chemical Properties: How materials will react to different chemicals – Stainless Steel Thermal Properties • Thermal Properties: How materials will react to temperature