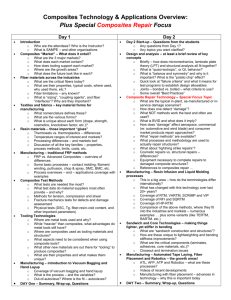

File

advertisement

NTSB - AA587 NTSB - AA587 NTSB - AA587 NTSB - AA587 NTSB - AA587 NTSB - AA587 NTSB - AA587 NTSB - AA587 NTSB - AA587 Pilot? Accident Reconstruction Tollbooth Cameras Construction Site Accident Reconstruction Movie Pilot Error? • • A300-600 is not fly-by-wire Maximum rudder deflection at 250 knots (VA) • • • • AA Training Guide FAA Pilot’s Handbook of Aeronautical Knowledge • • Pedal force = 10 lbs Pedal Travel = 1.25 inches “any combination of flight control usage, including full deflection of the controls, or gust loads should not create an excessive air load if the airplane is operated below mauneuvering speed” “The Myth of Maneuvering Speed”, Flying Magazine Types of Fiber Reinforcement • Whiskers: smallest, nearly perfectly crystalline, extremely strong and stiff (e.g. graphite, SiC, Al2O3, etc.) • Fibers: small diameter, polycrystalline or amorphous (e.g. aramids, glass, carbon, SiC, etc.) • Wires: relatively large diameter (e.g. steel, tungsten, molybdenum, etc.) Modulus (GPa) 1000 carbon nanotubes whiskers 100 fibers wires 10 Diameter Fiber Weave Patterns More Complex Fiber Weaves Prepreg Production • Prepreg: Tape of thermoset polymer and fiber reinforcement pre-impregnated with curing agent • • Parts made by “lay-up” of tape • • • Must be stored below room temp to slow curing Hand cut to shape Manually control orientation High temperatures and pressures to cure • Vacuum bag in autoclave Hand Lay-up Lay-up Steps (simple panel) Tape Placement (7-axis!!) Applications of Hand Lay-up www.owenscorning.com/composites/applications Warpage Pultrusion • Used to fabricate • • • Rovings or tows • • • Long, continuous parts Constant cross-section Impregnated with matrix Pulled through steel die for shape Properties often highly unidirectional Applications of Pultrusion www.owenscorning.com/composites/applications/ www.pultruders.com/ Filament Winding • • • • • • Used to fabricate • • Hollow parts Usually radial symmetry Fibers or tows • • Impregnated with matrix Continuously wound onto mandrel Usually automated winding equipment Various winding patterns used Excellent strength-to-weight Very economically attractive Properties vs. Winding Angle F di do L • • Modulus of Elasticity • Rule of mixtures estimate • • 3-point bending problem • Ecs=cos q*(EmVm+ EfVf) Usually concerned with tubes in bending - minimize deflection FL3 y 48 EI I 4 d o d i4 64 Applications of Filament Winding www.owenscorning.com/composites/applications/ www.advancedcomposites.com Applications of Filament Winding www.owenscorning.com/composites/applications/ www.advancedcomposites.com Resin Transfer Molding • • • • • Used to fabricate – Intricate 3-D shapes Fiber preform captured in closed steel mold Matrix is injected Preform may be complex – Braided, – Woven, or – Simple random mat (SRIM) Closed tooling provides good dimensional stability Applications of RTM www.owenscorning.com/composites/applications/consumer/sports.html Press Forming (Compression Molding) • • • Similar to compression molding polymers – Mold heated – Mold closes and applies pressure – Plastic becomes viscous – Conforms to mold shape May be used for thermoplastic matrices Geometry usually limited Applications of Press Forming www.owenscorning.com/composites/applications Injection Molding • Very similar to injection molding polymers • • Can inject chopped fibers with matrix into closed die Fibers usually rather short due to screw Applications of Injection Molding www.owenscorning.com/composites/applications Structural & Laminated Composites • • Laminate composite: • 2-D layered structure designed for high strength in preferred directions Sandwich panel: • Structure with strong outer layers and rigid but light inner core (e.g. skis) Applications of Laminates www.owenscorning.com/composites/applications http://www.hexcelcomposites.com/Markets/Markets/Sports www.nikebiz.com Machining Problems • Usually must use secondary operations on composites • Trim edges • Cut holes • Fasteners • Attachments • Access for wiring, assembly, maintenance • Holes will always act as stress concentrations • Kt 3 • Fatigue often initiated from these points • Holes need to be drilled as “damage free” as possible such that concentration does not increase Machining Problems • For machining parameters to choose: • • • • • Tool speed Feed rate Tool geometry Coolant For polymer composites this is difficult • Matrix: soft, ductile, hygroscopic • • Fiber: hard, brittle, abrasive • • Want to absorb water in coolant Tools wear very quickly Hard to achieve damage free holes and edges Common Composite Damage • Fiber breakage • Broken fibers do not carry load effectively near the hole • Matrix chip-out • Geometric discontinuity near hole • Delamination • Tool feeds perpendicular to ply, separating from bulk • Local fiber reinforcement is not balanced • Matrix overheating • Locally melt surface • Results in rough finish, clogged tool • In some applications load carrying capacity not important • Visual rejection still a possibility! Composite Machining Damage (SEM Images) 1000x 500x Fiber Breakage and Chipout Matrix Chipout 200x 500x Matrix Overheat Exit Side Debond