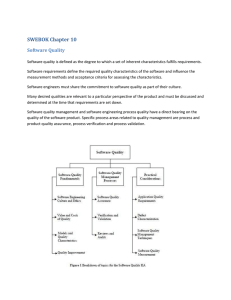

quality

advertisement

Management of Quality Chapter 9 Learning Objectives • You should be able to: 1. Define the term quality as it relates to products and as it relates to services 2. Explain why quality is important and the consequences of poor quality 3. Identify the determinants of quality 4. Distinguish the costs associated with quality Instructor Slides 2 Quality Management Quality The ability of a product or service to consistently meet or exceed customer expectations 9-3 Which has higher quality? • Rolls Royce • vs. • Toyota Tacoma • Performance, Aesthetics, Special features, Conformance, Reliability, Durability, Perceived quality, Serviceability 4 Dimensions of Product Quality • Performance – main characteristics of the product • Aesthetics – appearance, feel, smell, taste • Special features – extra characteristics • Conformance – how well the product conforms to design specifications • Reliability – Dependable performance • Durability – Ability to perform over time • Perceived quality – indirect evaluation of quality (reputation) • Serviceability – handling of complaints or repairs (Garvin, 1987) 9-5 Dimensions of Service Quality • Convenience – the availability and accessibility of the service • Reliability – ability to perform a service dependably, consistently, and accurately • Responsiveness – willingness to help customers in unusual situations and to deal with problems • Time – the speed with which the service is delivered • Assurance – knowledge exhibited by personnel and their ability to convey trust and confidence • Courtesy – the way customers are treated by employees • Tangibles – the physical appearance of facilities, equipment, personnel, and communication materials • Consistency – the ability to provide the same level of good quality repeatedly (Zeithhaml et al., 1990 & Evans et al., 1996) 9-6 Benefits of Good Quality Enhanced reputation for quality Ability to command premium prices Increased market share Greater customer loyalty Lower liability costs Fewer production or service problems Lower production costs Higher profits 9-7 The Consequences of Poor Quality • • • • Loss of business Productivity Costs Liability 9-8 Costs of Quality • Prevention Costs – Cost of preventing defects from occurring Planning, administration, working with vendors, training, quality assurance, process control, design and production. • • Appraisal Costs – Costs of activities designed to ensure quality or uncover defects Inspectors, testing, test equipment, labs, quality audits, quality control, field testing • • Failure Costs • costs incurred by defective parts/products or faulty services. Internal Failure Costs Costs incurred to fix problems that are detected before the product/service is delivered to the customer. External Failure Costs All costs incurred to fix problems that are detected after the product/service is delivered to the customer 9-9 Costs of Quality • Conformance Quality • how closely the actual product conforms to the chosen design specifications Cost of Assurance $ (Prevention + Appraisal) Total Cost Failure Cost of (Internal + External) Conformance Quality Optimum 10 Costs of Quality • Spending money on prevention saves even more money on failure costs. • It is possible to have high quality and (relatively) low cost at the same time. • “quality is free” (Crosby), and firms should get it “right the first time.” 9-11 Quality Contributors* Contributor Key Contributions Shewart Control charts; variance reduction Deming 14 points; special vs. common causes of variation Juran Quality is fitness-for-use; quality trilogy Feigenbaum Quality is a total field; the customer defines quality Crosby Quality is free; zero defects Ishikawa Cause-and-effect diagrams; quality circles Taguchi Taguchi loss function Ohno and Shingo Continuous improvement 9-12 Quality Awards and Certification* • Quality Awards – Deming Prize – Malcolm Baldrige National Quality Award http://www.nist.gov/baldrige/ – European Quality Award • Quality Certifications – ISO 9000/1 – International Organization for Standardization – Set of international standards on quality management and quality assurance, critical to international business 9-13 Six Sigma • Six Sigma – A methodology for improving quality, reducing costs, and increasing customer satisfaction – Statistically • Having no more than 3.4 defects per million – Conceptually • Sustained quality improvement requires commitment from the entire organization ("Champions", "Master Black Belts", "Black Belts", "Green Belts", “Yellow belts” ). • Every manufacturing and business processes have characteristics that can be measured, analyzed, improved and controlled. • Continuous efforts to achieve stable and predictable process results (i.e., reduce process variation/defects) 9-14 Basic Quality Tools 9-15 Basic Quality Tools 9-16 Operations Strategy* • Quality is a strategic imperative for organizations – Customers are very concerned with the quality of goods and services they receive • Quality is a never-ending journey – It is important that most organizational members understand and buy into this idea • Quality needs to be incorporated throughout the entire supply chain, not just the organization itself 9-17