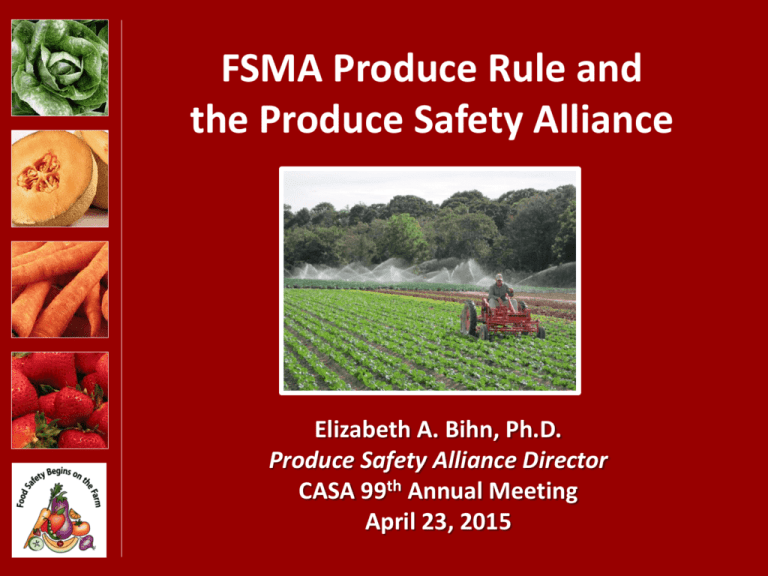

FSMA Produce Rule and the Produce Safety Alliance

advertisement

FSMA Produce Rule and the Produce Safety Alliance Elizabeth A. Bihn, Ph.D. Produce Safety Alliance Director CASA 99th Annual Meeting April 23, 2015 Key Goals for Today • Summarize FSMA Produce Rule • Share info about the Produce Safety Alliance (PSA) 2 FDA Food Safety Modernization Act Produce Safety Rule • Draft released 1-4-13 • Supplemental released 9-29-14 • Final Rule expected October 2015 • Proposed Produce Rule: Focus on the growing, harvesting, and post-harvest handling of produce • Focus is on the prevention, not detection of issues Produce Rule: Areas of Focus – Agricultural water – Biological soil amendments – Domesticated and wild animals – Personnel qualifications, training, and health and hygiene – Equipment, tools, buildings, and sanitation Do you have any idea why there areas are included? Definition of a ‘Farm’ • Farm means an establishment under one ownership in one general physical location devoted to growing and harvesting crops, the raising of animals (including seafood), or both. Pack/hold raw ag commodities Pack/hold processed food, provided that all processed food is consumed on that farm or on another farm under the same ownership Manufacture/process food that is not consumed on the farm but consists only of dehydrating/drying commodities, packaging and labeling without additional processing Definition of a ‘Farm’ • Why does the definition of a ‘farm’ matter? On-farm packing and holding of produce are not subject to PC Rule unless they meet the definition of processing or manufacturing Farms that pack or hold produce from another farm are not subject to the PC Rule A farm would not need to register as a food facility merely because it packs or holds raw agricultural commodities grown on another farm under different ownership Proposed Agricultural Water Standards for surface water that contacts the edible portion of the crop <126 CFU/MPN generic E. coli per 100 ml, geometric mean (n=5) AND a statistical threshold value of <410 CFU/MPN generic E. coli per 100 ml How Often Should You Test Surface Water? Source: Surface Water Testing Frequency Baseline 20 samples over 2 years Annually Minimum 5 samples per year If annual test does not support water quality profile Current annual survey, combined with new data for a total of 20 samples Establishing a Water Quality Profile for Surface Water START: Establish water quality profile Take 20 samples over two years ANNUALLY: Take 5 samples Compare to established water quality profile SAMPLING DOES MATCH PROFILE: Continue to test 5 samples annually TEN YEAR RE-EVALUATION: Take 20 samples to establish a new water quality profile SAMPLING DOES NOT MATCH PROFILE: Use the 5 annual samples, plus an additional 15 new samples (20 total) to establish a new profile - APPLY ALTERNATE METHODS: - Time interval to achieve 0.5 log microbial die-off per day between water application and harvest - Time interval between harvest and end of storage to achieve microbial die-off - Other activities that may achieve microbial die-off, i.e. washing - Discontinue use Soil Amendments • FDA has proposed deferring action on the use of raw soil amendments and has proposed to remove the 9 month application interval • FDA will be working with USDA ARS to facilitate research, risk assessment, and incentivizing composting practices Proposed Exemptions 1. Produce rarely consumed raw 2. Produce destined for ‘kill-step’ processing 3. Produce for personal/on-farm consumption 4. Make <$25,000 in all produce sales (3 year average) Proposed Qualified Exemptions • Farms may be exempt if they: Average gross sales of food sold in previous 3 years is <$500,000 AND Sell to qualified end users either: A. Direct to consumer B. Restaurant, retail food establishment in same state or within 275 miles of where produce was grown Produce Farms Exempt or Not Covered by the Produce Rule 189,000 Total Produce Farms 35,000 Covered 154,000 Exempt/ Not covered Growers may be exempt from the regulation, but not from the market place. FSMA Time Frame…in Theory! Jan 2013 Nov 2013 Public Comment End November 22, 2013 We are here Draft Rule Released Fall 2014 Oct 2015 Very small growers ($25-250K) comply 4 years Large growers (>$500K) comply 2 years 20162017 20162018 20162019 Final rule published in Federal Register Supplemental Comments Due Dec. 15th Small growers ($250-500K) comply - 3 years 2020+ Add an additional 2 years to each business size for compliance with the water standards How is it likely is it to impact fresh produce growers? How is it likely is it to impact state food and drug officials? It Depends! Which is why it is good to be talking about it now! 16 We are here! Things you should know about FSMA and produce safety! www.producesafetyalliance.cornell.edu 18 Produce Safety Alliance Focused on education and extension to assist growers with meeting regulatory and market food safety requirements • Cooperative agreement between Cornell University, FDA, and USDA • Established in October 2010 Target Audiences • Fresh produce growers, packers, and grower cooperatives with special emphasis on small and very small scale farms and packinghouses – Not to the exclusion of any farmer • Regulatory personnel – As part of their training • All others interested in produce food safety, GAPs, and co-management Primary Goals • Education and outreach to improve understanding and implementation of Good Agricultural Practices (GAPs), co-management strategies and regulatory requirements • Collecting and providing access to information related to produce safety, GAPs, comanagement and FDA's produce safety regulation • GAPs Education and Training Materials Conference in June 2011 • Producesafetyalliance.cornell.edu More Primary Goals • Develop a standardized educational curriculum to increase understanding of produce safety issues and co-management strategies to reduce risks to fresh produce – As proposed, training will be required as part of the FSMA Produce Rule • Build national networks • Train trainers to build cadre of qualified instructors • Conduct grower trainings • Collaborate for international training Curriculum Development Process Complete: May 2012 Complete: June 2012 • 10 WCs, 72 calls • 178 Unique WC Members • 549 Total WC Members • 8 Nationwide grower focus groups Complete: Dec 2012 Produce Safety Alliance Curriculum ~ Seven hours of dedicated instruction including: • Worker Health, Hygiene, and Training • Water • Soil Amendments • Wildlife and Domestic Animals • Facilities, Equipment, and Tools • How to Develop a Farm Food Safety Plan Completion of course results in certificate from Association of Food and Drug Officials (AFDO) to meet regulatory requirement for training PSA Right Now! • Just about ready for national launch – Pilots Complete! – Final edits and review of evaluations • Building collaborative networks • Finalize trainer certification process – Competency areas and interview Process • Finish AFDO certification specifics • Expanding the PSA – Hiring regional PSA personnel Future Work • Train-the-trainer workshops to build a network of qualified trainers across the country • Make grower trainings widely available and accessible • *Prepare growers to meet market demand and regulatory requirements * Training will begin BEFORE release of the final produce rule. Challenge #1: Building Cadre of Qualified Trainers • Diverse expertise required – Produce microbiology and production • Ability and desire to be involved – Extension people already busy or GONE – Private trainers need to make it pay • Funding – Growers have limited funds to pay for all associated expenses • Trainers required to be trained – Expense and effort involved Challenge #2: Reaching Growers • Located in rural locations and in every state • Diversity in geographical location • Many are exempt from the regulation But not the MARKETPLACE ! Expected to have produce safety knowledge • Sell into markets that do not have produce safety pressure…yet • Small vs Large Operations Things on the Horizon • Water Testing • Labs, labs, labs • Water Calculations • Geometic Means • Statistical Threshold Values • Manure application window • Sanitation questions • Sanitary design (buildings and equipment) • Detergents and sanitizer options • Sanitation practices on the farm Beyond the PSA Curriculum • PSA curriculum is a brain filling day • Growers need a written food safety plan • Third party audit • Buyer demand • Turning knowledge into action • Hands on activities • Implementing practices on the farm Options to Support Growers • Incorporate PSA training INTO current multi-day GAPs trainings Day 1: PSA certification Day 2: Farm food safety plan writing Already successful collaboration between Cornell, CCE, NYSDAM Long-term survey data shows progress • Continuing education Online and in-person modules Hands-on workshops o Postharvest water management Access to New Educational Materials www.gaps.cornell.edu 32 Each Decision Tree Portfolio Has… • Overview of the topic • Decision tree • Sample Standard Operating Procedures (SOPs) • Sample log sheets • Template food safety language Co-Management Information http://ucfoodsafety.ucdavis.edu/Preharvest/CoManagement_of_Food_Safety_and_Sustainability/ 34 Training Materials: Foodborne Illness Stories http://www.lgma.ca.gov/2014/12/dan-sutton-impact-stories-real-people/ 35 Summary • Collaboration has been key to our progress and will be the foundation of our success • Focused on providing information and training growers need to maintain markets and meet regulatory requirements • Will expand to meet regulatory personnel needs and integrate it with grower training • Provide a trail of how progress has occurred • Always open to ideas and ways to improve 36 The PSA Website http://producesafetyalliance.cornell.edu/ • You can even friend us on Facebook! • Join the listserve! • Contact us! Elizabeth A. Bihn, Ph.D., PSA Director, eab38@cornell.edu, 315.787.2625 Gretchen L. Wall, M.S., PSA Coordinator, glw53@cornell.edu, 607.255.6806