Document

advertisement

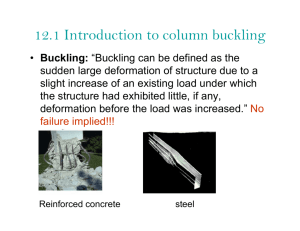

SECTION 7 DESIGN OF COMPRESSION MEMBERS © Dr S R Satish Kumar, IIT Madras 1 INTRODUCTION TO COLUMN BUCKLING • Introduction • Elastic buckling of an ideal column • Strength curve for an ideal column • Strength of practical column • Concepts of effective lengths • Torsional and torsional-flexural buckling • Conclusions 2 INTRODUCTION • Compression members: short or long • Squashing of short column • Buckling of long column • Steel members more susceptible to buckling compared to RC and PSC members 3 ELASTIC BUCKLING OF EULER COLUMN Assumptions: • Material of strut - homogenous and linearly elastic • No imperfections (perfectly straight) • No eccentricity of loading • No residual stresss 4 ELASTIC BUCKLING OF EULER COLUMN Pcr The governing differential equation is y d 2 y Pcr .y 0 2 EI dx x Lowest value of the critical load Pcr 2 E I cr A A 2 2E r2 2E 2E cr 2 2 2 ( / r ) Pcr 2 EI 2 5 STRENGTH CURVE FOR AN IDEAL STRUT axially loaded initially straight pin-ended column f 1 B Column fails when the Plastic yield defined compressive stress is greater C by than or equal to the values fy fy f = A A defined by ACB. Elastic buckling ( ) cr defined by 2 E / AC Failure by yielding (Low slenderness ratios) CB Failure by bucking ( c ) 2 B c = /r 6 STRENGTH CURVE FOR AN IDEAL STRUT f /fy Plastic yield Elastic buckling 1.0 1.0 = (fy / cr )1/2 Strength curve in a non-dimensional form 7 FACTORS AFFECTING STRENGTH OF A COLUMN IN PRACTICE: • Effect of initial out of straightness • Effect of eccentricity of applied loading • Effect of residual stress • Effect of a strain hardening and the absence of clearly defined yield point • Effect of all features taken together 8 Residual Stresses Residual stresses in web Residual stresses in flanges Residual stresses distribution (no applied load) Residual stresses in an elastic section subjected 9 to a mean stress a Effect of all features taken together a fy Data from collapse tests Theoretical elastic buckling Lower bound curve (E/fy)1/2 /r 10 SECTION 7 DESIGN OF COMPRESSION MEMBERS 7.1 Design Strength 7.2 Effective Length of Compression Members 7.3 Design Details 7.3.1 Thickness of Plate Elements 7.3.2 Effective Sectional Area 7.3.3 Eccentricity for Stanchions and Columns 7.3.4 Splices ]7.4 Column Bases 7.5 7.4.1 Gusseted Bases 7.4.2 Slab Bases Angle Struts 7.5.1 Single Angle Struts 7.5.2 Double Angle Struts 7.5.3 Continuous Members 7.5.4 Combined Stresses © Dr S R Satish Kumar, IIT Madras Cont... 11 7.6 7.7 7.8 SECTION 7 DESIGN OF COMPRESSION MEMBERS Laced Columns 7.6.1 General 7.6.2 Design of Lacings 7.6.3 Width of Lacing Bars 7.6.4 Thickness of Lacing Bars 7.6.5 Angle of Inclination 7.6.6 Spacing 7.6.7 Attachment to Main Members 7.6.8 End Tie Plates Battened Columns 7.7.1 7.7.2 General Design of Battens 7.7.3 Spacing of Battens 7.7.4 Attachment to Main Members Compression Members Composed of Two Components Back-to-Back © Dr S R Satish Kumar, IIT Madras end 12 INTRODUCTION c fy Test data (x) from collapse tests on practical columns xxx x x 200 Euler curve xx x x xx x x Design curve x 100 x x 50 xx x x 100 150 Slenderness (/r) Typical column design curve © Dr S R Satish Kumar, IIT Madras 13 Cross Section Shapes for Rolled Steel Compression Members (a) Single Angle (d) Channel (b) Double Angle (c) Tee (e) Hollow Circular (f) Rectangular Hollow Section (RHS) Section (CHS) © Dr S R Satish Kumar, IIT Madras 14 Cross Section Shapes for Built - up or fabricated Compression Members (a) Box Section (d) Plated I Section (b) Box Section (c) Box Section (e) Built - up I Section (f) Built-up Box Section © Dr S R Satish Kumar, IIT Madras 15 7.1 DESIGN STRENGTH 7.1.2 The design compressive strength of a member is given by Pd Ae f cd f y / m0 f cd 0.5 2 2 f y / m0 f y / m0 = 0.5[1+ ( - 0.2)+ 2] fcd = the design compressive stress, λ = non-dimensional effective slenderness ratio, f y fcc = Euler buckling stress = 2E/(KL/r)2 f cc 2 2 f y KL E r = imperfection factor as in Table 7 = stress reduction factor as in Table 8 © Dr S R Satish Kumar, IIT Madras 16 Table 10 Buckling Class of Cross-sections Cross Section Limits Rolled I-Sections h/b > 1.2 : tf 40 mm 40 < tf <100 z-z y-y z-z y-y a b b c Welded I-Section tf <40 mm z-z y-y z-z y-y b c c d tf >40 mm Buckling about Buckling Curve axis Hollow Section Hot rolled Cold formed Any Any a b Welded Box Section, built-up Generally Any Any b c Any c Channel, Angle, T and Solid Sections © Dr S R Satish Kumar, IIT Madras 17 7.1 DESIGN STRENGTH Buckling Curves 1 0.9 a 0.8 b c 0.7 fcd/fy 0.6 d 0.5 0.4 0.3 0.2 0.1 0 0 0.5 1 1.5 2 2.5 3 Lamda TABLE 7.1 IMPERFECTION FACTOR, α Buckling Class a b c d 0.21 0.34 0.49 0.76 © Dr S R Satish Kumar, IIT Madras 18 7.2 Effective Length of Compression Members (Table 11) Boundary Conditions At one end At the other end Translation Rotation Translation Rotation Restrained Restrained Free Free Effective Length Schematic represen -tation 2.0L Free Restrained Restrained Free Restrained Free Restrained Free 1.0L Restrained Restrained Free Restrained 1.2L Restrained Restrained Restrained Free 0.8L Restrained Restrained Restrained Restrained 0.65 L © Dr S R Satish Kumar, IIT Madras 19 7.4 COLUMN BASES 7.4.2 Gusseted Bases 7.4.3 Slab Bases t s 2.5 w (a 2 0.3b 2 ) m0 / f y tf a © Dr S R Satish Kumar, IIT Madras b 20 STEPS IN THE DESIGN OF AXIALLY LOADED COLUMNS Design steps: • Assume a trial section of area A = P/150 • Make sure the section is at least semi-compact ! • • Arrive at the effective length of the column. Calculate the slenderness ratios. • • Calculate fcd values along both major and minor axes. Calculate design compressive strength Pd = (fcd A). • Check P < Pd © Dr S R Satish Kumar, IIT Madras 21 BEHAVIOUR OF ANGLE COMPRESSION MEMBERS U • Angles under compression – Concentric loading - Axial force 1. Local buckling 2. Flexural buckling about v-v axis V 3. Torsional - Flexural buckling about u-u axis – Eccentric loading - Axial force & bi-axial moments – Most practical case U – May fail by bi-axial bending or FTB – (Equal 1, 2, 3 & Unequal 1, 3) V © Dr S R Satish Kumar, IIT Madras V U V U 22 7.5 ANGLE STRUTS Basic compressive strength curve • Curve C of Eurocode 3 • Slenderness Ratio: concentric loading Single leg Connection kL/r (kl/r)eq Equivalent normalised slenderness ratio k1 k 2 k 3 2 e 2 vv 2 Where, k1, k2, k3 are constants to account for different end conditions and type of angle. © Dr S R Satish Kumar, IIT Madras 23 vv KL r vv 2E 250 b1 b2 E 2 250 2t Where L = laterally unsupported length of the member rvv = radius of gyration about the minor axis b1, b2 = width of the two legs of the angle t = thickness of the leg ε = yield stress ratio ( 250/fy)0.5 © Dr S R Satish Kumar, IIT Madras 24 7.5 ANGLE STRUTS 7.5.1.2 Loaded through one leg k1, k2, k3 = constants depending upon the end condition (Table 12) e k1 k22vv k32 No. of bolts at the each end connection Gusset/Connec -ting member Fixity† k1 k2 k3 Fixed 0.20 0.35 20 Hinged 0.70 0.60 5 Fixed 0.75 0.35 20 Hinged 1.25 0.50 60 >2 1 Design ? © Dr S R Satish Kumar, IIT Madras 25 DESIGN CONSIDERATIONS FOR LACED AND BATTENED COLUMNS (a) Single Lacing (b) Double Lacing (c) Battens Built-up column members © Dr S R Satish Kumar, IIT Madras 26 LACED AND BATTENED COLUMNS 7.6.1.5 The effective slenderness ratio, (KL/r)e = 1.05 (KL/r)0, to account for shear deformation effects. 7.7.1.4 The effective slenderness ratio of battened column, shall be taken as 1.1 times the (KL/r)0, where (KL/r)0 is the maximum actual slenderness ratio of the column, to account for shear deformation effects. © Dr S R Satish Kumar, IIT Madras 27 Dr S R Satish Kumar Department of Civil Engineering IIT Madras Chennai 600 036 sr.satishkumar@gmail.com © Dr S R Satish Kumar, IIT Madras 28