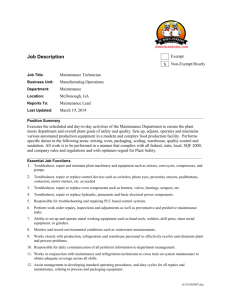

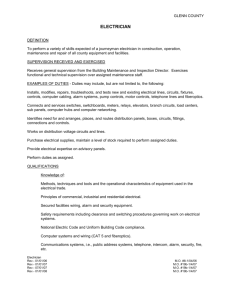

Electrician Job Description

advertisement

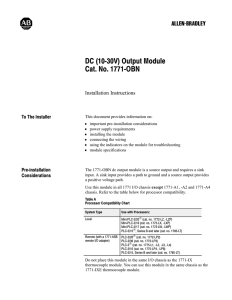

Purpose: Electrician will be responsible for troubleshooting, programming and repair of PLC's, AC/DC Motors, conveyors, and gearboxes Prior experience as maintenance electrician/mechanic is a must. Need to possess California Electrician license or millwright certification AC/DC ELECTRICAL, BLUEPRINT READING, PLC PROGRAM, CONVEYOR LAYOUT, GEARBOXES, HYDRAULIC/PNEUMATIC Job Description Work with the latest high tech industrial equipment for an exciting company. Electrical maintenance Engineer: Carry out and develop Routine Preventative Maintenance systems Respond to emergency breakdowns onsite. Call out required. Maintenance, fault finding and rectification of faults on electrical control systems. Fault finding of DCS, PLC, and network IO systems. Allen Bradley preferred. Maintenance, fault finding and calibration of instrumentation and control equipment. Qualified / Competent in working on electrical systems up to 480Vac Installation of new equipment and relocation of equipment Assist with mechanical and electrical improvements to plant and equipment Maintain and repair environmental emissions control systems General facility maintenance Spare parts management Ensure the adherence to Safe working practices, policies, and procedures Ensuring all documentation and recording of work is completed to a high standard Troubleshooting motors and controls, Reading mechanical/electrical blueprints, Hydraulics, pneumatics, conveyor systems, Maintenance & Repair, Preventative Maintenance, Facilities Maintenance Essential Duties and Responsibilities: Follow instructions given by shop supervisor. Layout and wire control panels with components such as motor starters, PLCs, control relays, terminals, etc. Label all wiring to print. Test each console to ensure proper wiring. Calibrate sensors. Place consoles onto main systems and wire to all external devices per code. Must be able to follow directions and work with minimal supervision, conform to company standards of assembly methodology, and balance their workload with multiple priorities. May also be required to perform other duties as necessary. Essential skills: Able to troubleshoot and resolve electrical and electrical controls issues in circuits containing transformers, disconnects, over current protection devices, and general control components (relays, timers, etc). Able to troubleshoot and resolve automated controls issues on PLC/computer-controlled production equipment. Able to execute electrical and controls upgrades and repairs to equipment. Must be very detail oriented to ensure proper wiring and code compliance, while also being able to get work done on time to conform to production schedules. Able to read and interpret ladder diagrams. Education & Experience: High school diploma. Associate degree in EET or equivalent experience is preferred. Minimum 5 years of experience as an industrial electrician with primary duties as an electrical controls technician in a manufacturing environment. Experience working with electrical distribution and control systems up to 480 VAC, 3PH; able to efficiently troubleshoot, repair, and modify PLC based control systems; experience troubleshooting and applying pneumatic valves, actuators (pneumatic and electric), sensors (thermocouples, pressure transducers, etc), electric motors, and other typical automation components. . Experience building machine control centers utilizing ladder diagrams and device documentation. Must be able to effectively communicate in English, and be able to distinguish between various wiring colors. Must be able to lift 50 pounds, and kneel, bend and stand for extended periods of time. Work Environment: While performing the duties of this job the employee must be must be able to communicate clearly with supervisors, peers, or subordinates by phone, in writing, and / or in person; Must be able to tell when an operating error is occurring and assist in deciding what to do about it; must be able to work within a team environment; must possess the ability to maintain accurate records and pay close attention to detail. Physical Demands: 1. Standing for long periods of time. 2. Ability to keep your hand and arm steady while moving your arm or while holding your arm and hand in one position. 3. Ability to see details at close range, at a distance through peripheral vision, and the ability to adjust focus. 4. Ability to quickly and repeatedly adjust the controls of a machine to exact position. 5. Ability to quickly move your hand, your hand together with your arm, or your two hands to grasp, manipulate, or assemble objects. 6. Use of hands to finger, handle, or feel objects, tools or controls. 7. Reaching with hands and arms. 8. Talking and hearing. 9. Occasional walking, stooping, crawling, kneeling, or crouching. 10. Driving golf cart from one department to another. 11. Repeatedly lifting, tugging and/or moving up to 50 pounds (at times it may be necessary to lift more.)