Development of innovative products made of flax chaff for adsorption

advertisement

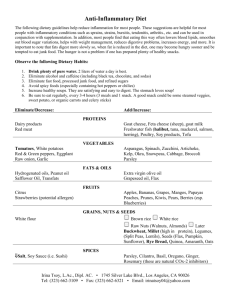

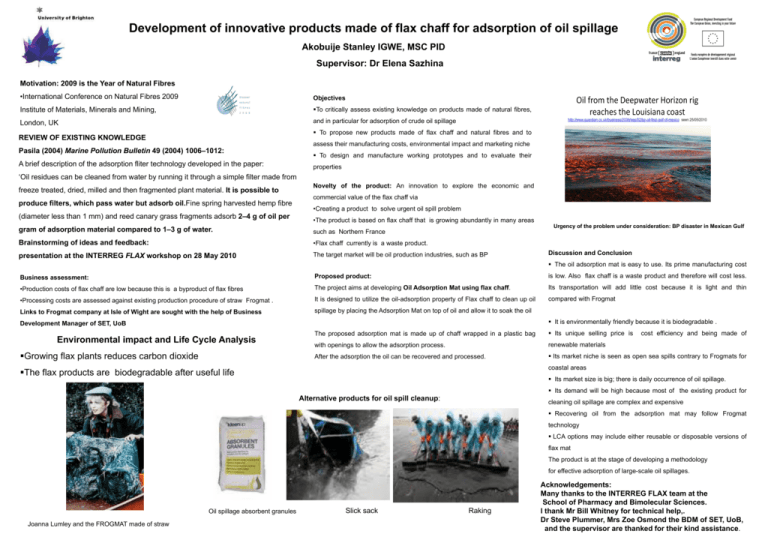

Development of innovative products made of flax chaff for adsorption of oil spillage Akobuije Stanley IGWE, MSC PID Supervisor: Dr Elena Sazhina Motivation: 2009 is the Year of Natural Fibres •International Conference on Natural Fibres 2009 Objectives Institute of Materials, Minerals and Mining, To critically assess existing knowledge on products made of natural fibres, London, UK and in particular for adsorption of crude oil spillage To propose new products made of flax chaff and natural fibres and to REVIEW OF EXISTING KNOWLEDGE assess their manufacturing costs, environmental impact and marketing niche Pasila (2004) Marine Pollution Bulletin 49 (2004) 1006–1012: A brief description of the adsorption fliter technology developed in the paper: To design and manufacture working prototypes and to evaluate their properties ‘Oil residues can be cleaned from water by running it through a simple filter made from freeze treated, dried, milled and then fragmented plant material. It is possible to produce filters, which pass water but adsorb oil.Fine spring harvested hemp fibre (diameter less than 1 mm) and reed canary grass fragments adsorb 2–4 g of oil per Novelty of the product: An innovation to explore the economic and commercial value of the flax chaff via •Creating a product to solve urgent oil spill problem •The product is based on flax chaff that is growing abundantly in many areas Urgency of the problem under consideration: BP disaster in Mexican Gulf gram of adsorption material compared to 1–3 g of water. such as Northern France Brainstorming of ideas and feedback: •Flax chaff currently is a waste product. presentation at the INTERREG FLAX workshop on 28 May 2010 The target market will be oil production industries, such as BP Discussion and Conclusion The oil adsorption mat is easy to use. Its prime manufacturing cost Business assessment: Proposed product: is low. Also flax chaff is a waste product and therefore will cost less. •Production costs of flax chaff are low because this is a byproduct of flax fibres The project aims at developing Oil Adsorption Mat using flax chaff. Its transportation will add little cost because it is light and thin •Processing costs are assessed against existing production procedure of straw Frogmat . It is designed to utilize the oil-adsorption property of Flax chaff to clean up oil compared with Frogmat Links to Frogmat company at Isle of Wight are sought with the help of Business spillage by placing the Adsorption Mat on top of oil and allow it to soak the oil It is environmentally friendly because it is biodegradable . Development Manager of SET, UoB Environmental impact and Life Cycle Analysis Growing flax plants reduces carbon dioxide The proposed adsorption mat is made up of chaff wrapped in a plastic bag Its unique selling price is with openings to allow the adsorption process. renewable materials After the adsorption the oil can be recovered and processed. Its market niche is seen as open sea spills contrary to Frogmats for cost efficiency and being made of coastal areas The flax products are biodegradable after useful life Its market size is big; there is daily occurrence of oil spillage. Its demand will be high because most of the existing product for Alternative products for oil spill cleanup: cleaning oil spillage are complex and expensive Recovering oil from the adsorption mat may follow Frogmat technology LCA options may include either reusable or disposable versions of flax mat The product is at the stage of developing a methodology for effective adsorption of large-scale oil spillages. Oil spillage absorbent granules Joanna Lumley and the FROGMAT made of straw Slick sack Raking Acknowledgements: Many thanks to the INTERREG FLAX team at the School of Pharmacy and Bimolecular Sciences. l thank Mr Bill Whitney for technical help,. Dr Steve Plummer, Mrs Zoe Osmond the BDM of SET, UoB, and the supervisor are thanked for their kind assistance.