acid

advertisement

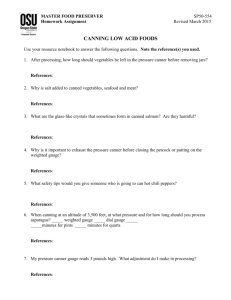

Wisconsin’s Pickle Bill 2010 Selling Home-Canned Foods • Wisconsin Act 101 allows a person to sell some home-canned foods without a license (under certain conditions) • You can sell without a license fruits and vegetables that are naturally acidic or have been acidified by pickling or fermenting – Pickled fruits and vegetables – Salsas – Sauerkraut – Jams and jellies 2 Products you Can’t Sell under the Pickle Bill Exemption • Low-acid canned foods: vegetables, fish, meat • Sauces, dressings or condiments (these are not considered fruits or vegetables) • Canned foods that are not considered ‘fruits or vegetables’: lemon curd, pesto, pickled eggs, etc. • Baked goods • Dried, processed or packaged foods 3 Requirements • Annual registration with the Food Safety Division of the Dept of Ag Call 608-224-4682 to register. • No more than $5,000 in sales per household per year • Retail sales only (direct from producer to consumer) and only in Wisconsin • Sales only at community or social events, farmers’ markets, or farm roadside stands 4 NO Sales • • • • • • • • Out of your home Wholesale (resale by someone else) On consignment Via the internet OR out of state Of food produced outside of your kitchen Of food produced by someone with a license At craft shows, carnivals, school events, etc Of exempt food (pickle bill products) along with licensed foods 5 Other Requirements • Annual pH testing for the first batch of each product (includes jams, jellies, pickles, salsa, fermented kraut, etc) – Using a calibrated pH meter for pH greater than 4.0 – pH paper is OK for products with pH 4.0 or lower (using a testing lab is recommended but not required) • Training in home-canning safety or use of an approved recipe 6 Sources of Approved Recipes • Ball Blue book (current edition) • Ball Complete Book of Home Preserving • The National Center for Home Food Preservation www.uga.edu/nchfp • University of Wisconsin Extension www.foodsafety.wisc.edu 7 Signs and Labels • Sign at the point of sale: These products are homemade in a kitchen that has not been subject to state inspection • On each jar: “This product was made in a home not subject to state licensing or inspection.” Also on each jar: – Name and address of person who did the canning – Date of canning – Ingredients in decreasing order of predominance 8 Keep Complete Records Keep written records of each batch of product for 2 years including: – Name of product – Recipe, including procedures and ingredients – Amount canned and sold – Canning dates – Sales dates and locations – Gross sales receipts – Results of any pH tests 9 Questions? • Legal requirements: Wisconsin Dept of Ag – 608-224-4682 – food@wi.gov • Canning processes and recipes: UW-Extension – Your county office – UW-Extension specialist Dr. Barbara Ingham • 608-263-7383 • bhingham@wisc.edu 10 Home Canning: Do It Safely Microorganisms •Microorganisms which can grow and cause spoilage or illness must be destroyed in the canning process Rod-shaped E. coli O157:H7 •Our worry in canned food: • Clostridium botulinum • C. botulinum is found naturally in soil • Spores are VERY heat resistant • Growing spores produce a toxin when acid is low Yeast cells Cells and spores of C. botulinum 12 Factors that Affect the Growth of Microbes • Food – be sure to clean & sanitize • Acid – add enough acid, and the right kind, to keep botulinum toxin from forming • Temperature – a jar on a shelf may be the perfect temperature for microbial growth • Oxygen – some microbes need air to grow – C. botulinum grows only in sealed packages where oxygen isn’t present (a sealed canning jar can be ideal!) For acid and acidified canned foods, ACID is KEY 13 ACID •pH is a measure of the amount of acid •The pH scale ranges from 1 to 14 •A solution with pH between 1 and 7 is acid; a solution with pH between 7 and 14 is alkaline, or basic. A solution pH 7 is neutral. 14 pH and Acid pH 1 2 3 4 7 8 9 Acid [H+] 0.1 0.01 0.001 0.0001 0.0000001 0.00000001 0.000000001 Notation 1 x 10-1 1 x 10-2 1 x 10-3 1 x 10-4 1 x 10-7 1 x 10-8 1 x 10-9 Acid/Base Acid Acid Acid Acid Neutral Base Base 15 Relationship Between pH & Acid • • • • The lower the pH, the higher the acid The higher the pH, the lower the acid Increasing pH by 1, decreases acid 10-times A food with pH greater than 4.6 is considered ‘low acid’ • A food with pH 4.6 or lower is ‘high acid’ 16 Average pH Values of Food Food Item pH Food Item pH Lemons Oranges Strawberries Grapes 2.2 3.0 3.0 4.0 Beef Pork Chicken Lettuce 6.0 6.0 6.0 6.0 Tomatoes Cheese Carrots 4.0 * 5.0 6.0 Fish Milk Seafood 6.5 6.2 7.5 Potatoes 6.0 Egg white 8.0 Many foods are mixtures of high-acid and low-acid ingredients. *Tomatoes must be acidified to be safely canned. 17 pH and Growth of Microbes • Yeast and mold grow at a lower pH than bacteria • Most bacteria grow best at a pH of 6.0-7.0 (they have a minimum and maximum for growth) • pH can be adjusted to control the growth of microorganisms • pH is critical to controlling the growth of Clostridium botulinum 18 TEMPERATURE • Psychrotrophs (cold growing) –Grow best 58°F to 68°F –Grow slowly in refrigerator (40°) • Mesophiles*(warm loving) –Grow best 86°F to 98°F –C. botulinum is a concern • Thermophiles (hot loving) –Grow best 122°F to 150°F Many pathogens are mesophiles. Clostridium botulinum • • • • • Spore-forming bacterium Anaerobe (grows without oxygen) Found naturally in soil Spores germinate at pH greater than 4.6 When spores germinate and grow, they produce a potent neurotoxin • Some spores are very heat tolerant, surviving hours of boiling 20 Condition for neurotoxin formation: • Anaerobic environment • pH greater than 4.6 • Temperature above 40°F Growing cells produce TOXIN 21 ‘Recipe’ for Danger 1 Food, pH above 4.6 1 Vacuum-sealed canning jar 1 Room @ standard temperature ADD: C. botulinum spores WAIT! You don’t need to add these, they can be isolated from soil or water practically anywhere in the world! 22 Botulism Strikes Spokane Mother, Two Children February 28, 2009 …The Associated Press reported that three people in Spokane, Washington, have become ill from botulism. The botulism apparently occurred from improper canning techniques used in home-canning of green beans from a private home garden. The woman was a nurse in her 30s with two children under ten. She became ill enough to be put on a ventilator; the children suffered milder symptoms. The incident was linked to difficult economic times. 23 Measuring pH • Foods with pH 4.0 or less – pH test paper (colorimetric) – A color change is compared to a standard in order to determine pH • Foods with pH greater than 4.0 – pH meter is required – The amount of acid in solution (H+) is related to an electrical potential and a numerical result is generated List of testing labs: www.foodsafety.wisc.edu/assets/pdf_Files/Testing_Labs_0110.pdf 24 Effective Acidifiers [Not all acids are created equal!] • Acetic acid is the acid in vinegar. Use vinegar standardized to 5% acetic acid. Homemade vinegar, balsamic vinegar, wine vinegar are not standardized to 5% acidity and should not be used. Cider vinegar (5% acetic acid) can be used. • Citric acid is the acid found in citrus fruits. It is available as a solid, or added as bottled lemon juice. It is the most commonly used acid in foods due to its low cost and high acid strength. • Ascorbic acid (vitamin C) is not an effective acidifier; it is used as an antioxidant to prevent browning of light-colored fruits. Other acidifiers: lactic, phosphoric, etc. can also be used. Follow label-use directions. 25 Canning Terms • Headspace –the unfilled space above food or liquid in jars; allows food to expand and a vacuum seal to form • Hot-fill –heating foods to boiling, packing in hot sanitized jars, sealing, and holding at a high temperature for a given time (hot-fill-hold) • Hot pack –placing hot food into hot jars before processing. Different from raw pack which places raw food into hot jars. 26 Establishing a Canning Process …writing a recipe that will work! • Set the ingredients and amounts • Check pH of your first batch of each recipe each year (must be less than or equal to 4.6 for all products) • Use and always follow a tested recipe • Heat process to stabilize product and ensure a seal – Boiling water or steam canning – Hot-fill-hold 27 Establishing a Canning Process …other things to keep in mind Adjust for elevation when canning! • Water boils at a lower temperature as elevation increases – Increase processing time for boiling water canning – All darker-shaded areas are above 1,000 feet and require recipe adjustment Sources of pre-approved recipes – USDA Complete Guide to Home Canning www.uga.edu/nchfp/ - 1994 or later – UWEX Safe Food Preservation Series (2008) www.foodsafety.wisc.edu 28 A Brief Review: Boiling Water Canning • Place prepared jars in 6” of water in canner. – Hot packed jars - simmering water (180°F) – Raw packed jars - hot water (140°) • Place jars on rack in canner. • Water must be over the tops of the jars by at least 1 inch. • Begin timing when water reaches an active boil. • Adjust for elevation. 29 2 3 1 Steps in Canning Salsa 1. Canner with lid 2. Jars &lids 3. Fill hot jars with hot salsa 4. Check headspace 5. Wipe jar rims before 4 applying lid 5 30 Steps in Canning Salsa (cont). 6. Place jars in canner filled ½-way with hot water 7. Process in boiling water – water covers jar lids by 1-2 inches 8. At the end of processing, remove jars and cool 7 6 8 31 After Processing…Now What? • Allow containers to cool away from drafts – Do NOT touch or tighten closures while cooling! • Once cool: check for vacuum seal • Sell only jars that are sealed and produced from an approved recipe 32 Labeling your Jars • • • • Name of the Product Name and Address of the Producer Ingredient Statement (most to least) Canned foods should be labeled: For Date or Lot Code quality, refrigerate after opening “This product was made in a home not subject to state licensing or inspection.” 33 High Quality Products from Your Kitchen • Use only equipment in good working order –Beware of rusted pots or pans, damaged or heavily scarred cutting board • Keep all kitchen surfaces clean (including hands) –Keep pets out of the kitchen! • People handling food must be healthy –Protect food from open sores –Use hair restraints 34 Cleaning and Sanitizing • Clean all raw agricultural products – water only, don’t use bleach or soap • Water must be of good sanitary quality • Clean all equipment after each use (removing food debris helps keep microbes at bay) • Sanitizing after cleaning to destroy microorganisms that remain on clean surfaces 35 Sanitizing Sanitizing always follows cleaning. Common sanitizers for equipment and surfaces: • Immerse 30 sec in clean, hot water (170°F+) • Immerse 2 min in warm chlorine (75°-110°F) – 100-200 ppm available Cl– 1 Tablespoon bleach per gallon of water • NOTE: more is NOT better! 36 Kitchen Checklist Safe water Well maintained working areas & equipment Cross contamination is avoided Non-food chemicals properly used & stored Pest control safe and effective, family pets at bay Good health & hygiene for anyone handling food 37 Something Special from your Kitchen 38