Design and Synthesis of a Variety of 3-Alkylanilines

advertisement

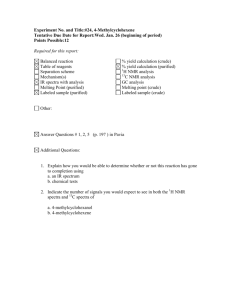

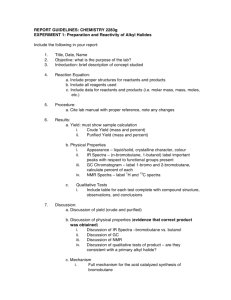

Design and Synthesis of a Variety of 3-Alkylanilines: Multiple and Varied Synthetic Approaches for Intermediates for Potential Antibacterial Compounds. Mark McGill* and Bruce A. Hathaway Southeast Missouri State University Cape Girardeau, MO 63701 Overview 3-alkylanilines are required for the synthesis of 3-alkylphenyltriazines, a class of potential antibacterial compounds. Though there are many potential routes to 3-alkylanilines, one must consider the nature and position of the substituents on the benzene ring in order to select a suitable and logical pathway to the desired product. For example, the difficulty of placing an alkyl group (or useful transformational group) on a deactivated nitrobenzene ring. Synthetic Outline Considering this aspect of synthetic planning, three different approaches to the 3-alkylaniline synthesis were chosen for investigation. These include: the Wolff Kishner reduction of nitrated alkyl phenyl ketones, catalytic hydrogenation of Wittig derived alkenes, and catalytic hydrogenation of Sonogashira alkyne coupling reactions. Nitration-Reduction Scheme O O HNO3, H2SO4 R R Cold (Corson & Hazen) R = any alkyl chain + O O R 2 + + O - N O 5 NH2NH2 KOH Diethylene Glycol reflux - N O R 2 + 6 H2O 5 N2 NH2 Three trials were attempted for the nitration of alkyl phenyl ketones with subsequent Wolff Kishner reduction of the Trial 1 product. The Trial 3 product currently awaits reduction. Nitration-Reduction Results Trial 1 2 3 Trial 1 2 Nitration of Alkyl Phenyl Ketones Product Weight Melting Point 3-nitroacetophenone 3.44 g 61 °C - 66 °C 3-nitropropiophenone --N/A 3-nitropropiophenone NMR Confirms No Confirms Wolff Kishner Reduction of 3-Nitroacetophenone Product Weight Melting Point NMR 3-ethylaniline 6.968 g liquid Confirms 3-ethylaniline 6.071 g liquid Confirms % Yield 20.86% N/A % Yield 117.62% 82.41% Difficulty maintaining cold temperature with nitration. Nitration yields need to be improved. Wolff-Kishner reduces both ketones and nitro groups. Nitration-Reduction Discussion Multiple procedures are available for nitration reactions. Generally, one can cool ~15 mL of concentrated sulfuric acid in an ice bath and add alkyl phenyl ketone with stirring. Add nitrating mixture (cold 2:3 nitric acid:sulfuric acid) dropwise, but keep the temperature below 0° - then stir 10 minutes more. Pour over cracked ice and water with stirring. Work-up varies from washing to extraction with ether. The Wolff-Kishner reduction simply involves refluxing alkyl 3-nitrophenyl ketones with hydrazine hydrate and HO- in diethylene glycol. Overall yields could be improved with nitration optimization. Nitration of Benzophenone O O HNO3, H2SO4 (Cold) * Adams, Johnson, Wilcox + O - N O A procedure similar to previously discussed nitration gave yield to a mixture of products. A 24 hour reflux in ethanol left some undissolved solid. Hot filtration gave yield to two different solids: 2.74 grams of what appears by NMR to be relatively pure di-nitrated benzophenone as well as 5.24 grams of an impure mixture of nitrated (and di-nitrated) benzophenone. Nitration worked, but not selectively. Friedel-Crafts Acylation Experiment O O Cl O Benzene + N O Trial 1 AlCl3, O + N O Friedel-Crafts Acylation Experiment Product Weight Melting Point NMR 4-nitrobenzophenone 2.568 Confirms % Yield 22.29% The Friedel-Crafts Acylation reaction was utilized to generate product that would reduce to yield an aniline with an sp3 carbon bonded to a benzene ring. This could be modified to yield a 3-alkylaniline. Wittig – Catalytic Reduction Scheme P(C6H5)3 R Br p-Cymene (* Delmas) Br R - P(C 6H5)3 R - any alkyl group Br R - P(C 6H5)3 NaOH, 1,4-dioxane R 3-nitrobenzaldehyde + O - N O R Ethanol, 5% Pd/C R + + O - N O 4 H2 + 2 H2O in Parr Shaker NH2 Wittig-Catalytic Reduction Results Wittig - Catalytic Reduction by Reaction Step Step Product Weight Melting Point NMR 1 hexyltriphenylphosphonium bromide 66.15 g 180 °C Confirms 2 1-(3-nitrophenyl)-hept-1-ene 1.404 g N/A Confirms 3 3-heptylaniline (impure) 0.934 g N/A Confirms % Yield 77.32% 24.29% 76.24% Viable route to 3-alkylanilines. Reduction product difficult to purify. Alternative procedures and modifications could be applied to help increase yield. Wittig Procedure Discussion In a round bottom flask, 0.200 moles of 1-bromohexane, 250 mL p-Cymene, and 0.200 moles triphenylphosphine were refluxed 3 hours. Next, 8.57 grams (0.020 mol) of solid product from this reflux were added to a mixture of 0.0753 moles solid NaOH, 20 mL 1,4 dioxane (w/0.5 mL H2O), and 0.020 moles of 3-nitrobenzaldehyde to reflux for 4 hours. The dark solution was filtered and the filtrate rotary evaporated. This oil was washed with pentane, filtered and evaporated again. The oil was purified by a crude silica column using CH2Cl2 as eluent. Both alkene isomers were reduced catalytically using a Parr Shaker. Sonogashira Alkyne Coupling: Reduction to 3-Alkylanilines R Br + Alkyne Stir under Nitrogen 24 Hrs. + O - CuI, (Ph3P)2PdCl2, Et2NH, (Room °C) N O + O O - N O 5 H2 + N O Pd (cat.) H2N R R This experiment was repeated for 1-hexyne, 1-heptyne, 1-octyne, 1-decyne, and 1-dodecyne. Coupling Reaction Results Sonogashira Coupling of Alkynes with 1-bromo-3-nitrobenzene Melting Alkyne Product Weight NMR Point 1-octyne 1-(3-nitrophenyl)-oct-1-yne 0.875 g N/A Confirms 1-dodecyne 1-(3-nitrophenyl)-dodec-1-yne 1.961 g N/A Confirms 1-hexyne 1-(3-nitrophenyl)-hex-1-yne 2.779 g N/A Confirms 1-heptyne 1-(3-nitrophenyl)-hept-1-yne 3.40 g N/A Confirms 1-decyne 1-(3-nitrophenyl)-dec-1-yne 4.29 g N/A Confirms % Yield 48.61% 42.72% 86.04% impure impure Incredibly difficult to purify (both alkyne and reduction). Reductions are not guaranteed or clear cut. Does provide 2-step method to 3-alkylanilines. Reduction Results Reduction of Sonogashira Coupled Alkynes Melting Reduction Product Weight NMR Point 3-octylaniline 0.786 g N/A Confirms 3-dodecylaniline 0.727 g N/A Confirms 3-hexylaniline 2.779 g N/A Confirms 3-heptylaniline 3.40 g N/A No 3-decylaniline 4.29 g N/A No % Yield 94.74% 40.84% 85.07% impure impure NMR confirms the successful reduction to form 3-octylaniline, 3-dodecylaniline, and 3-hexylaniline with relative purity. NMR indicates that the reductions of 1-(3-nitrophenyl)-hept-1-yne and 1-(3-nitrophenyl)-dec-1-yne were only partially complete when the reaction ended. Sonogashira Scheme Discussion This path has proven successful for generating moderate yields of reasonably pure 3-alkylanilines. Purification of the alkyne products was attempted by column chromatography using 1:19 Ethyl Acetate:Hexane as eluent. Perhaps a more effective method would be to initiate the column using hexane as the eluent. Then, one could gradually increase polarity with ethyl acetate – which would allow for greater control of the separation. Also, the reductions that should have produced 3-heptylaniline and 3-decylaniline ceased prematurely. This can be remedied by running the reduction reactions again. Conclusion This path has proven successful for generating moderate yields of reasonably pure 3-alkylanilines. Purification of the alkyne products was attempted by column chromatography using 1:19 Ethyl Acetate:Hexane as eluent. Perhaps a more effective method would be to initiate the column using hexane as the eluent. Then, one could gradually increase polarity with ethyl acetate – which would allow for greater control of the separation. Also, the reductions that should have produced 3-heptylaniline and 3-decylaniline ceased prematurely. This can be remedied by running the reduction reactions again. Further Work This path has proven successful for generating moderate yields of reasonably pure 3-alkylanilines. Purification of the alkyne products was attempted by column chromatography using 1:19 Ethyl Acetate:Hexane as eluent. Perhaps a more effective method would be to initiate the column using hexane as the eluent. Then, one could gradually increase polarity with ethyl acetate – which would allow for greater control of the separation. Also, the reductions that should have produced 3-heptylaniline and 3-decylaniline ceased prematurely. This can be remedied by running the reduction reactions again.

![[VO(H2O)5]H[PMo12O40]-catalyzed nitration of alkanes with nitric acid](http://s3.studylib.net/store/data/007395962_1-c5684ccdbf5a6a8d13576cb676ea7c0b-300x300.png)