sir_Production planningLectur

advertisement

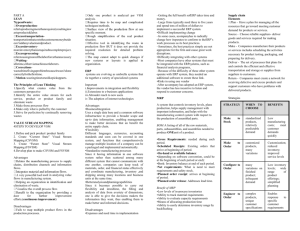

Objectives After completing this chapter, you will be able to: • Describe the steps in the production planning process of a high-volume manufacturer such as Fitter Snacker • Describe Fitter Snacker’s production and materials management problems • Describe how a structured process for Supply Chain Management planning enhances efficiency and decision making • Describe how production planning data in an ERP system can be shared with suppliers to increase supply chain efficiency 1 1 Production Overview • To meet customer demand efficiently, Fitter Snacker must: – Develop a forecast of customer demand – Develop a production schedule to meet the estimated demand • ERP system is a good tool for developing and executing production plans • Goal of production planning is to schedule production economically 2 Production Overview (cont’d.) • Three general approaches to production – Make-to-stock items: made for inventory (the “stock”) in anticipation of sales orders – Make-to-order items: produced to fill specific customer orders – Assemble-to-order items: produced using a combination of make-to-stock and maketo-order processes 3 Capacity Planning • Capacity planning is a long-term strategic decision that establishes a firm's overall level of resources. • long time horizon: usually a year or more for building new facilities or acquiring new businesses. • Capacity decisions affect product lead times, customer responsiveness, operating costs, and a firm's ability to compete. • Inadequate capacity can lose customers and limit growth. Excess capacity can drain a company's resources and prevent investments in more lucrative ventures. When to increase capacity and how much to increase capacity are critical decisions. Strategy of Timing Capacity Expansion • Capacity lead strategy. Capacity is expanded in anticipation of demand growth. This aggressive strategy is used to lure customers from competitors who are capacity constrained or to gain a foothold in a rapidly expanding market. • Capacity lag strategy. Capacity is increased after an increase in demand has been documented. This conservative strategy produces a higher return on investment but may lose customers in the process. It is used in industries with standard products and cost-based or weak competition. The strategy assumes that lost customers will return from competitors after capacity has expanded. • Average capacity strategy. Capacity is expanded to coincide with average expected demand. This is a moderate strategy in which managers are certain they will be able to sell at least some portion of the additional output. Factors Affecting Capacity Expansion • How much to increase capacity depends on – the volume and certainty of anticipated demand; – strategic objectives in terms of growth, customer service, and competition; and – the costs of expansion and operation. • Capacity can be increased incrementally • Incremental expansion is less risky but more costly. • An attractive alternative to expanding capacity is outsourcing, in which suppliers absorb the risk of demand uncertainty. The Production Planning Process • Three important principles for production planning: – Work from sales forecast and current inventory levels to create an “aggregate” (“combined”) production plan for all products – Break down aggregate plan into more specific production plans for individual products and smaller time intervals – Use production plan to determine raw material requirements 7 The SAP ERP Approach to Production Planning Concepts in Enterprise Resource Planning, Third Edition Figure 4-2 The production planning process 8 Production Planning and Control • • Production Planning is one of the main function of a production Manager. This is concerned with determining the QUANTITY and TIMING of production for the FUTURE. Isn’t it DIFFICULT! Production manager try to determine the BEST way to meet forecasted demands by: 1. Adjusting production rates 2. Adjusting manpower levels 3. Inventory levels 4. Overtime works 5. subcontracting Decision-making in Operations Management • • • 1. 2. 3. 4. 5. 6. Operations managers are decision makers. What makes the difference between a Good Decision and a Bad Decision? “Good’ decision = logic + Data + Alternatives • Steps Define the problem and the factors that influence it Establish decision criteria and goals Formulate a model (relation between goals and variables) Identify and evaluate alternatives Select BEST alternative Implement the decision Quantitative Analysis Logic Historical Data Market research Scientific analysis Modeling Decision Problem ? Qualitative Analysis Emotions Intuition Personal experiences Rumors The Planning Process • Planning Short Term Medium Term (begins once long term capacity decisions are made. Monthly and quarterly plans, AGGREGATE PRODUCTION PLAN – related to operation managers – Tactical Scheduling decisions) Long Term (Facility Location and expansion, New product development, Research funding, investment over several years, strategic issues – related to Top Management) Master Production Scheduling (MPS) • Objectives • Determine the quantity and timing of completion of end items over a short-range planning horizon. • Schedule end items (finished goods and parts shipped as end items) to be completed promptly and when promised to the customer. • Avoid overloading or under loading the production facility so that production capacity is efficiently utilized and low production costs result. Time Fences The rules for scheduling 1-2 weeks 2-4 weeks 4-6 weeks 6+ weeks +/- 5% +/- 10% +/- 20% Change Change Change No Change Frozen Firm Full Open Detailed Scheduling • Detailed plan of what is to be produced, considering machine capacity and available labor • One key decision in detailed production scheduling – How long to make the production runs for each product – Production run length requires a balance between setup costs and holding costs to minimize total costs to the company 15 Detailed Scheduling (cont’d.) • Fitter Snacker uses repetitive manufacturing • Repetitive manufacturing environments usually involve production lines that are switched from one product to another similar product – Production lines are scheduled for a period of time, rather than for a specific number of items 16 Detailed Scheduling (cont’d.) • Production runs should be decided by evaluating the cost of equipment setup and holding inventory • Integrated information system simplifies this analysis – Automatically collects accounting information that allows managers to better evaluate schedule trade-offs in terms of costs to company 17 Materials Requirements Planning (MRP) • Determines required quantity and timing of the production or purchase of subassemblies and raw materials needed to support MPS • Bill of material (BOM): list of the materials (including quantities) needed to make a product 18 Materials Requirements Planning (MRP) Figure 4-16 The bill of material (BOM) for Fitter Snacker’s NRG bars 19 Materials Requirements Planning (MRP) • Lead times and lot sizing – Lead time: cumulative time required for the supplier to receive and process the order, take the material out of stock, package it, load it on a truck, and deliver it to the manufacturer – Lot sizing: determining production quantities and order quantities • MRP record: standard way of viewing the MRP process on paper 20 Materials Requirements Planning (MRP) (cont’d.) Figure 4-17 The MRP record for oats in NRG bars, weeks 1 through 5 21 Production – Inventory System # # 25 Day Delay to sense needs, place and transmit orders 5 Day Delay to sense needs, place and transmit M.O.s 25 Day Delay for Review and Transmission of orders Information Flow Material Flow Days for transit time Days to process or to handle and issue orders 13 Day Delay for Review and Transmission of orders Demand Raw Material Vendor Factory Factory Warehouse 35 30 Distributor Inventory 4 1 Company System Under Retail Inventory 2 10 1 5 50 Independent Distributors Managerial Control Production Planning Ultimate Customer 1 500 Independent Retailers Dynamo.xls 22