COURSE TITLE (COURSE CODE)

advertisement

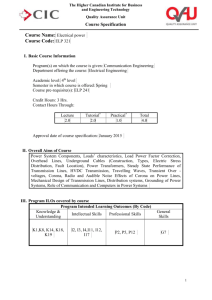

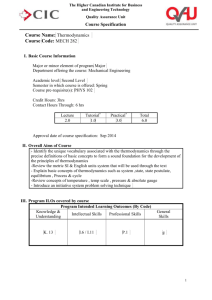

The Higher Canadian Institute for Business and Engineering Technology Quality Assurance Unit Course Specification Course Name: Facility Planning & Design Course Code: IEN 316 I. Basic Course Information Program(s) on which the course is given: Industrial Engineering Department offering the course: Mechanical Engineering Academic level: 4th level Semester in which course is offered : Spring Course pre-requisite(s): Work design & Measurements (IEN 281) Credit Hours: 3.0 Contact Hours Through: Lecture 2.0 Tutorial* 2.0 Practical* 1.0 Total 5.0 Approval date of course specification: September 2014 II. Overall Aims of Course -Introduction: Facilities requirement, types of layout. Plant location: Plant location analysis, factors, costs, location decisions, simple problems in single facility location models, network problems. Product, process, and Schedule design. Activity relationship. Layout design: SLP procedure, computer algorithms – ALDEP, ALDEP. QUANTITATIVE METHODS: Group technology (GT) – Production Flow analysis (PFAFT), Rank Order Clustering (ROC) – Line balancing. Materials handling: Principles, unit load concept, material handling system design, handling equipment types, selection specification, containers and packaging III. Program ILOs covered by course Program Intended Learning Outcomes (By Code) Knowledge & Intellectual Skills Professional Skills Understanding K.13/K.20 I.17 P.11 General Skills G.h 1 The Higher Canadian Institute for Business and Engineering Technology Quality Assurance Unit Course Specification IV. Intended Learning Outcomes of Course (ILOs) a. Knowledge and Understanding On completing the course, students should be able to: k. 1 Identify the Concepts of Facility Planning k. 2 Recognize the common types of facilities k. 3 Recognize the difference between process and product layout k. 4 Classify different types of assembly lines b. Intellectual/Cognitive Skills On completing the course, students should be able to: i.1 Assess and evaluate different types of facilities layout i.2 Plan optimum facilities locations i.3 Judge different facilities locations i.4 Plan for material handling techniques i.5 Solve for network problems c. Practical/Professional Skills On completing the course, students should be able to: p.1 Demonstrate the different techniques of facilities design p.2 Demonstrate different types of facilities p.3 Solve the facility planning problem using staffing and balancing work cells problems p.4 Sketch different types of layout plans d. General and Transferable Skills On completing the course, students should be able to: g.1 effectively manage the quality of an organization through the learned methods and tools V. Course Matrix Contents Main Topics / Chapters -Introduction: 1- Facilities requirement types of layout. 2- Plant location: Plant location analysis, factors, 3- costs, location decisions simple problems in 4- single facility location models 5- network problems 6- Product, process 7- Schedule design Duration (Weeks) Course ILOs Covered by Topic (By ILO Code) K&U I.S. P.S. G.S. 1 K1/K2/K3/K4 I1/I2/I3/I4/I5 P1/P2/P3/P4 G.1 1 K1/K2/K3/K4 I1/I2/I3/I4/I5 P1/P2/P3/P4 G.1 1 K1/K2/K3/K4 I1/I2/I3/I4/I5 P1/P2/P3/P4 G.1 1 K1/K2/K3/K4 I1/I2/I3/I4/I5 P1/P2/P3/P4 G.1 1 1 1 K1/K2/K3/K4 K1/K2/K3/K4 K1/K2/K3/K4 I1/I2/I3/I4/I5 I1/I2/I3/I4/I5 I1/I2/I3/I4/I5 P1/P2/P3/P4 P1/P2/P3/P4 P1/P2/P3/P4 G.1 G.1 G.1 2 The Higher Canadian Institute for Business and Engineering Technology Quality Assurance Unit Course Specification 8- 9- 10- 11- 12- 13- 14- Activity relationship . Layout design: SLP procedure, computer algorithms – ALDEP, ALDEP QUANTITATIVE METHODS: Group technology (GT) – Production Flow analysis (PFAFT) Rank Order Clustering (ROC) – Line balancing Materials handling: Principles, unit load concept, material handling system design, handling equipment types, , selection specification, containers and packaging Net Teaching Weeks 1 K1/K2/K3/K4 I1/I2/I3/I4/I5 P1/P2/P3/P4 G.1 1 K1/K2/K3/K4 I1/I2/I3/I4/I5 P1/P2/P3/P4 G.1 1 K1/K2/K3/K4 I1/I2/I3/I4/I5 P1/P2/P3/P4 G.1 1 K1/K2/K3/K4 I1/I2/I3/I4/I5 P1/P2/P3/P4 G.1 1 K1/K2/K3/K4 I1/I2/I3/I4/I5 P1/P2/P3/P4 G.1 1 K1/K2/K3/K4 I1/I2/I3/I4/I5 P1/P2/P3/P4 G.1 1 K1/K2/K3/K4 I1/I2/I3/I4/I5 P1/P2/P3/P4 G.1 14 VI. Course Weekly Detailed Topics / hours / ILOs Week No. 1 2 3 4 5 6 7 8 9 10 11 Sub-Topics -Introduction: Facilities requirement Total Hours 2 types of layout. Plant location: Plant 5 location analysis, factors, costs, location decisions 5 simple problems in single facility location 5 models network logation problems 5 Product, pocess 5 Midterm Exam Schedule design 5 Activity relationship 5 . Layout design: SLP procedure, computer 5 algorithms – ALDEP, ALDEP QUANTITATIVE METHODS: Group 5 Contact Hours Theoretical Practical Hours Hours* 2 2 3 2 3 2 3 2 2 3 3 2 2 3 3 2 3 2 3 3 The Higher Canadian Institute for Business and Engineering Technology Quality Assurance Unit Course Specification 12 13 14 15 technology (GT) – Production Flow analysis (PFAFT) Rank Order Clustering (ROC) – Line balancing Materials handling: Principles, unit load concept, material handling system design, handling equipment types, Final Exam Total Teaching Hours 5 2 3 5 2 3 5 2 3 62 26 36 Teaching/Learning Method Lectures & Seminars Tutorials Computer lab Sessions Practical lab Work Reading Materials Web-site Searches Research & Reporting Problem Solving / Problem-based Learning Projects Independent Work Group Work Case Studies Presentations Simulation Analysis Others (Specify): Selected Method VII. Teaching and Learning Methods 1 Course ILOs Covered by Method (By ILO Code) K1/K2/K3/K4 K1/K2/K3/K4 Intellectual Skills I1/I2/I3/I4/I5 I1/I2/I3/I4/I5 Professional Skills P1/P2/P3/P4 P1/P2/P3/P4 General Skills G.1 G.1 K1/K2/K3/K4 I1/I2/I3/I4/I5 P1/P2/P3/P4 G.1 K&U Selected Method VIII. Assessment Methods, Schedule and Grade Distribution Course ILOs Covered by Method (By ILO Code) Assessment Method K&U I.S. P.S. Midterm Exam Final Exam Quizzes Course Work Report G.S. 1 K1/K2/K3/K4 I1/I2/I3/I4/I5 P1/P2/P3/P4 G.1 1 1 K1/K2/K3/K4 K1/K2/K3/K4 I1/I2/I3/I4/I5 I1/I2/I3/I4/I5 P1/P2/P3/P4 P1/P2/P3/P4 G.1 G.1 Assessment Week Weight / No. Percentage 4 The Higher Canadian Institute for Business and Engineering Technology Quality Assurance Unit Course Specification Writing Case Study Analysis Oral Presentations Practical Group Project Individual Project Others (Specify): IX. List of References Essential Text Books Course notes Recommended books Periodicals, Web sites, etc … Groover, M.P., Automation, Production Systems, and Computer – Integrated manufacturing Prentice Hall, NJ,2008 Lectures X. Facilities required for teaching and learning White Board Course coordinator: Dr. Mahmoud Head of Department: Dr .Mahmoud Mohamed Date: September 2014 5