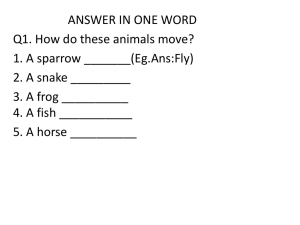

PPT

advertisement

EFFECT OF INCORPORATING “OXYDOL®” IN WHITE SHRIMP FARMING PONDS Litopenaeus vannamei OVER PRODUCTION AND PHYSICAL-CHEMICAL PARAMETERS MARCELO ATEHORTUA HERRERA Zootechnical Veterinarian Doctor BIOPHARM S.A. Panamá Atlanta, January 29, 2013 EFFECT OF INCORPORATING “OXYDOL®” IN WHITE SHRIMP FARMING PONDS Litopenaeus vannamei OVER PRODUCTION AND PHYSICAL-CHEMICAL PARAMETERS Points to consider: 1. Basic parameters on handling of ponds. 2. Dynamics of carbon in aquiculture . 3. Use of OXYDOL® for production of shrimps. 4. Field results and economical analysis. 5. Discussion 6. Conclusions BASIC PARAMETERS ON HANDLING OF AQUACULTURAL PONDS WATER REPLACEMENT Amount of oxigen dissolved Evaporation and filtering Water temperature Coloring Salinity Turbidity pH BASIC PARAMETERS ON HANDLING OF AQUACULTURAL PONDS TEMPERATURE Water temperature shall be between 25 and 32°C, being the optimal between 29 and31°C (Yoong Basurto y Reinoso Naranjo, 1982). SALINITY It can range between 28 and33 ppt (parts by thousand) (Cuellar, Lara, Morales, De Gracia 2010). BASIC PARAMETERS ON HANDLING OF AQUACULTURAL PONDS AMOUNT OF OXYGEN DISSOLVED Normal concentrations range between 4 and 7 ppm (mg/L). pH Optimal pH range is between 7.0 y 8.0 (Cuellar, Lara, Morales, De Gracia 2010). BASIC PARAMETERS ON HANDLING OF AQUACULTURAL PONDS TURBIDITY, must be greater than 30 cm COLOURING OF WATER Pale green: Indicates adequate concentration of algae Gray: Few algae in the pond, it is recommended more fertilization and replacemente of water. Moss green: Algae starts dying, it is required urgent need of water replacement. Brilliant green: High concentration of algae. Brown: High amount of dead algae, probably there is lack of nutrients and excess of metabolites. BASIC PARAMETERS ON HANDLING OF AQUACULTURAL PONDS FEEDING Take into consideration: FEEDING FREQUENCY It is convenient to feed the animals twice a day, in the morning and in the afternoon.. BASIC PARAMETERS ON HANDLING OF AQUACULTURAL PONDS QUANTITY AND QUALITY OF FEEDING Starts at 25 to 32 lb/ha/day with a 25 to 35% protein (Dirección Nacional de Acuicultura Panamá, 1984; CAMACO, 2013). SUBSTRATUM In general, penaeid live at soft mud bottoms, made by different proportions of sand, slime and clay, burying themselves and protecting from predators, mainly during the molting period; this behavior seems to be regulated by factors such as light, temperature and concentration of oxygen. DYNAMICS OF CARBON IN AQUICULTURAL PONDS Carbon added is transformed in form of food or organic and inorganic fertilization, due to the participation of physical, chemical and biological activities. Intensive production is accompanied by increase of carbon input as food, that in form of food exceeds the metabolic capacity of the pond, resulting on the accumulation of organic composites and deterioration to quality of the water. The greater output of carbon from the productive system is associated with the escape of gas in form of CO₂. The main means of CO₂ retention in the fish ponds is the phyoplankton. DYNAMICS OF CARBON IN AQUICULTURE POND (continuation) .) Carbon in ponds is determined by the type of food, feeding practices, specie farmed, water replacemenet, aeration, depth of the pond and living microorganisms. Carbon, together with nitrogen and phosporus are required in greater quantity at the different physical chemical reactions in the ponds. In the different metabolic processes occurring inside the ponds, carbon participates practically in all reactions and is the most abundant of all the organic molecules (Boyd, 1995). Dynamics of Carbon Food, Phytoplakton, Carbon entry. Shrimps, fish, aquiculture Ecosystem Organic material, excreta, moulting, water deterioration C, N and P, and biochemical reactions Sediment, Fertilizations Land harvest Organic material, gas emission. THE PROBLEM AT AQUICULTURAL PONDS Organic material in the bottom of the ponds Bad quality of water Natural unbalance of the aquicultural ecosystem THE PROBLEM WITH THE AQUICULTURAL PONDS As a result of this vicious circle: quality of water deteriorates to control it, it is not possible to mecanically make a sweep or cleaning of the ponds’ bottoms( favoring the occurrence of bacteria and opportunistic virus that end up affecting the population’s health in the lakes.) major economical loses to corporations occurr as a result of the foregoing. OXYDOL® Product designed based upon specific beneficial bacteria, enzymes, organic catalitics, stabilizers and potentiators for degradation of the organic material in the bottom of lakes used in intensive production. A bio secured alternative to improve aquicultural ecosystems and the physical chemical quality of water in production activities. OXYDOL®. Benefits Accelerates the degradation process and decresing organic waste. Controls proliferation of algae in the environment Allows oxygenation of the competing with other bacteria. environment, without OXYDOL® Benefits (continuation) Decreases concentration of ammonia, methane and sulphites in water. Restores the aquicultural chemistry by natural means increasing the shrimps’ survivorship in ponds. Allows conducting specific works in ponds such as: Death corners, oxygen problems, control of algae growth, treatment of charged waters, coloring, pigmentation in shrimps, significant decrease of odors and tastes. EFFECT OF INCORPORATING “OXYDOL®” IN WHITE SHRIMP FARMING PONDS Litopenaeus vannamei ON PRODUCTION AND PHYSICAL-CHEMICAL PARAMETERS The trial took place in Panama, with an important shrimp company, to evaluate the effect OXYDOL® over the main production variables in the farm. Evaluation conducted during a complete cultivation cycle between May and November 2012 in 10 ponds, of area 700-A in the area of Aguadulce. GOAL OF THE TRIAL To bio-remedy the bottom of the lake for intensive shrimp production: Improving the physical chemical parameters of water; Controlling emission of harmful gas; Promoting adequate sanity, sustainability, zootechnical production; Increasing profitability of aquicultural companies. MATERIALS AND METHODS (Shrimps and experimental units) Shrimps used in the trial were obtained at the Larva Production Center “C.P.L. San Carlos” (San Carlos, Panama) and were submitted to an acclimatization process of 10 days, then transferred to 10 experimental ponds at state of post-larva 22 (pl-22) 10 pounds were used (5 with OXYDOL® and 5 as Control) of 3 Has. each one in the area 700-A of the farm, said ponds were selected by similarity of size, type of bottoms, filling water and replacement water. MATERIAL AND METHODS (EXPERIMENTAL DESIGN AND TREATMENTS) The trial was conducted based upon a design of blocks totally at random, grouping ponds to form two treatments: OXYDOL ® treatment ponds 721 to 725 (5 replicas) Control treatment: ponds 716 to 720 (5 replicas) MATERIALS AND METHODS (PRODUCTION PARAMETERS TO EVALUATE) Physical chemical parameters (dissolved oxygen [OD in mg/L], temperature [in °C], salinity [in ppt] and pH) Survivorship (%) Production in pounds by hectare (lb/ha) Food conversion factor (FC) Weight of harvest (Weight g) Weekly growth (Growth gr) Cost-benefit relationship ($) MATERIALS AND METHODS (HANDLING OF PONDS) A preparation and filling protocol of the 10 ponds was routinaley used in the farm. Shrimps were planted in all the ponds with an average density of 15 15 pls/m2. Fertilization in water was made with ammonia Nitrate, according with the farm’s protocol (15-25 lb/ha). The post-larva pl-22, were fed during the whole cycle (200-209 days) twice a day by scattering standarized diet for both treatments, using “witnesses feeders” as guides. The ponds were kept closed with no water replacement during the first 30 cultivation days. OXYDOL®, Application protocol Dilute 1 Kilogram of OXYDOL® in 19 liters of water (free of chlorine) OXYDOL® Application Aplicación ® OXYDOL® Dose OXYDOL ® Initiation of cycle Dosis (Sowing)OXYDOL 2 Liters / Hectare 15 days 1 Liter / Hectare 30 days 1 Liter / Hectare 60 days 1 Liter / Hectare MATERIALS AND METHODS (REGISTRY OF DATA AND INFORMATION ANALYSIS) Weekly sampling of weight, data of physical chemical parameters was collected in the farm according to protocol for each one of them ( (OD and T, twice a day; salinity and pH once a week) Production values were provided by ALTRIX DE PANAMA processing plant. . Data was statistically analyzed by ANOVA, Duncan y Chi trials aligned with the SAS program, considering the differences as signicant when P 0.05. The Chi trial aligned was applied only to FC, for being a non parametric variable. CAMARONERA DE COCLE S.A. REPORT OXYDOL HARVEST Y . OXYDOL Pond Has. 721-48 Lbs/ Ha Dens F. Feed lb F/C Grwt 8,951 2,984 5.43 29,000 3.24 0.86 150,165 24.22 8,011 2,670 5.01 32,255 4.03 0.86 34 153,468 24.95 8,434 2,811 5.12 22,725 2.69 0.86 15.00 39 176,541 20.28 7,886 2,629 5.88 27,850 3.53 15.00 45 201,984 20.09 8,938 2,979 6.73 26,865 3.01 0.71 15.0 38 845,033 22.68 42,220 2,815 5.63 138,695 3.29 0.79 Weight Lbs. Lbs/ Ha Dens F. Feed lb F/C Grwt Sowing 3.00 Days Pl´s sowingDens %Svb Harvest s 11-may-12 30-nov-12 203 450,000 15.00 36 162,876 24.95 722-48 3.00 15-may-12 29-nov-12 198 450,000 15.00 33 723-48 3.00 11-may-12 30-nov-12 203 450,000 15.00 724-48 3.00 15-may-12 30-nov-12 199 450,000 725-48 3.00 15-may-12 30-nov-12 199 450,000 2,250,000 15.00 200 Pond Has. Sowing F. Sample Days Pl´s sowingDens %Svb Harvest Weight Lbs. 0.71 716-48 3.00 01-may-12 29-nov-12 212 450,000 15.00 27 122,083 25.92 6,970 2,323 4.07 32,725 4.70 0.86 CONTROL 717-48 3.00 05-may-12 29-nov-12 208 450,000 15.00 25 111,317 26.20 6,424 2,141 3.71 23,865 3.71 0.88 718-48 3.00 05-may-12 29-nov-12 208 450,000 15.00 30 136,370 24.00 7,209 2,403 4.55 23,155 3.21 0.81 719-48 3.00 05-may-12 29-nov-12 208 450,000 15.00 36 161,710 23.67 8,431 2,810 5.39 29,510 3.50 0.80 720-48 3.00 05-may-12 29-nov-12 208 450,000 15.00 26 119,220 28.02 7,358 2,453 3.97 28,825 3.92 0.94 2,250,000 15.0 29 650,699 25.39 36,392 2,426 4.34 138,080 2.79 15.00 209 0.85 RESULTS AND DISCUSSION Production media by treatment and statistics calculated for each variable. Treatrment ® Oxydol Control Diference (%) P CV n 5 5 ------Standard deviation --Media --- Sup % a 37.56 b 28.92 +29.9 0.0170 13.7 4.55 33.24 Weight g Lb/ha FC Grwt g a a 22.90 2,815 3.30 0.80 a b a a 25.56 2,426 3.81 0.86 -11.6 +16 -15.5 -7.5 0.0876 0.0190 0.670 0.2380 8.9 8.0 15.1 8.6 2.17 209.66 0.54 0.07 24.23 2,620.40 3.55 0.83 a a The media corresponding to the best production indexes for each variable ye and in each treatment The “P” values in yellow belong to those showing significant differences (P 0.05). RESULTS AND DISCUSSION( continuation) During cultivation were shown outbreaks caused by virus WSSV (white spot sindrome) according with expectations in the 01 experimental ponds, which was confirmed through polimerasa (Nested-PCR) chain tests reaction and hystopathology which in certain degree influenced in the final zootechnical parameters. Based upon these disease outbreakes, it is suggested that there was a positive tendency from using OXYDOL® over the shrimps’s survivorship, which showed a highly significant difference (P<0.05). RESULTS AND DISCUSSION (COST OF PRODUCT AT THE TRIAL) Cost of OXYDOL® in this trial was of $62.50 /ha. Considering that 15 hectare were treated (5 ponds at 3 hectares each one), the total cost of the product in the trial was of $937.50 To cover the cost of OXYDOL® in this trial and having a base price of $2.20 per lb of shrimp, it was required to produce 28.4 lb/ha more in the ponds with OXYDOL®, each hectare with OXYDOL® produced in average 389 pounds more than the Control. The product paid itself ~14 times. RESULTS AND DISCUSSION The majority of probiotics micro-organisms proposed for aquiculture belong to the acid-lactic bacteria (LAB), of which the genre more used are Lactobacillus and Lactococcus. These are considered as GRAS (“Generally recognized as safe”), a warranty that the implementation of isolated probotics will not cause collateral damage to the cultivated organisms or to the final consumers. Institute of Marine and Coastal Research INVEMAR 173; (Holzapfel et al., 1998). Use of probiotics as LAB is relatively well established in other animal specie (Wallace y Newbold, 1992; Aiba et al., 1998; Kontula et al., 1998; Kirjavainen et al., 1999a, 1999b; Netherwood et al., 1999), of them it oustands the increase on height and weight, establishment of an intestinal microbial equilibrium, as well as the improvement of some inmune responses. RESULS AND DISCUSSION Supply of exogenous LAB is also associated with the growth inhibition of the pathogen bacteria (Lewus et al., 1991; Gildberg et al., 1995; Santos et al., 1996), as growth promoter of the aquiculture specie (Noh et al., 1994) and in some cases, with an increase of shrimps’ survivorship experimentally infected (Gatesoupe, 1994; Gildberg, 1995; Robertson et al., 2000). Utilization of Gram-positive bacteria such as Bacillus, in general has shown to be beneficial in shrimp cultivation (L. vannamei), causing an important increase in the rates of survivorship and weight. (Jory, 1998). RESULTS AND DISCUSSION Bacteria of the Bacillus genre selected as probiotics can convert organic matter into O₂ , (Dalmin et al., 2001). Laloo et al. (2007) proved the capability of three isolated of the Bacillus genre to decrease concentration of nitrite, nitrate and ammonia in the cultivation water of ornamental fish. This same phenomena was also observed by Kim et al. (2005) en B. subtilus, B.cereus y B. licheniformis. Interaction between probiotic bacteria and micro algae in the cultivation ponds, in general produces positive effects, since it estabilizes the nutritional factors of the living feed, being able to contribute with the establishment of the beneficial intestinal micro flora of the host (Reitan et al., 1993, 1997). RESULTS AND DISCUSSION Without OXYDOL® With OXYDOL® CONCLUSIONS OXYDOL® treatment exceeded control in 3 of the 5 production variables with higher economical impact.: “survivorship”, “lb/ha” and“FC”. The first two showed significant differences (P<0.01). The variables “harvest weight” and “weekly growth”, were better at control, without showing signifcant differences. (P < 0.05). Cost of OXYDOL® used in this trial paid itself 14 times, based upon the incremental pounds of shrimps obtained regarding the Control. This difference of lb/ha obtained in favor of the product, suggests that keeping a consistent production system of cultivation shrimp could represent an economical increase. Thank you very much for your attention ¿Any questions? www.biopharm.com.pa