ERT 208/4 REACTION ENGINEERING

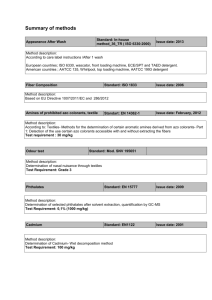

advertisement

ERT 208/4 REACTION ENGINEERING: Bioreaction in Bioreactors By; Mrs Hafiza Binti Shukor ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) Students should be able to; APPLY pseudo-steady-state hypothesis (PSSH) in gas-phase reactions and in order to DEVELOP rate laws. DESCRIBE reaction mechanism, chain reaction & reaction pathways utilizing biomolecular reaction (yeast fermentation) ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) Common form of the RATE LAW •homogeneous reaction, rA kC n A If n=1 (interger), reaction was 1 order If n=not interger number? CH 3CHO Eg, The rate law for the decomposition of acetaldehyde •Reaction involving active intermediate k1k3CI2 CH2 H 2 I 2 2 HI rHI k 2 k 3C H 2 CH 4 CO 3 2 CH3CHO rCH3CHO kC Reaction Order cannot de defined (polynomial fuction) NON ELEMTARY REACTION No direct correspondence between reaction order & stoichiometry Reaction Order are described only for limiting values of reactant and/or product conc. ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) Fundamentals of Nonelementary Reaction •For Gas-Phase Decomposition of azomethane, AZO CH 3 2 N 2 C2 H 6 N 2 EXPERIMENTAL OBSERVATIONS SHOWS ; rN2 C AZO 1st order at; •high conc •pressure >1atm rN2 C 2 AZO 2nd order at; •Low conc •Pressure < 50mmHg ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) Fundamentals of Nonelementary Reaction…cont… •Active Intermediates change in reaction order can be explained by the theory developed by Lindemann ‘ an active molecule, CH N @[ A*] results from collision or interaction between molecules’ 3 2 2 ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) Fundamentals of Nonelementary Reaction…cont… k1 CH 3 2 N 2 CH 3 2 N 2 * N CH N 2 3 2 2 2 CH 3 k1 A* M A M •Lindemann Theory the decomposition of intermediate does not occur instantaneously after internal activation of the molecule …rather, there is a time lag although infinitesimally small during which the species remains activated. •Other types of active intermediates that can be formed are; a) Free radicals (one @ > unpaired electrons like H) b) Ionic internidiates (eg. Carbonium ion) c) Enzymes substrate complexes ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) Fundamentals of Nonelementary Reaction…cont… k1 CH 3 2 N 2 CH 3 2 N 2 * N CH N 2 3 2 2 2 CH 3 rAZO* k1C 2 AZO where., AZO CH 3 2 N 2 2 reaction path that active intermediate may follow; CH 3 k2 CH 3 2 N 2 CH 3 2 N 2 N * CH N 2 3 2 2 2 rAZO* k 2 C AZOC AZO* CH 3 Activated molecule become deactivated through collision with another molecule k3 N * C2 H 6 N 2 2 2 rAZO* k3C AZO* where., Activated molecule decomposes spontaneously to form ethane & nitrogen ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) Fundamentals of Nonelementary Reaction…cont… CH 3 2 1. N 2 C2 H 6 N 2 The overall reaction is NON ELEMENTARY consist of sequence of ELEMENTARY reactions k1 CH 3 2 N 2 CH 3 2 N 2 * N CH N 2 3 2 2 2 CH 3 2 AZO molecules collide & the kinetic energy of one AZO molecule is transferred to internal rotational & vibrational energies of the other AZO molecule & it becomes activated & highly reactive. 2. CH 3 k2 CH 3 2 N 2 CH 3 2 N 2 N * CH N 2 3 2 2 2 Activated AZO* is deactivated through collision with another AZO 3. CH 3 k3 N * C2 H 6 N 2 2 2 Activated AZO* is widely vibrating, spontaneously decomposes into ethane & nitrogen Nitrogen & Ethane only form from 3rd equation. The net rate of formation of nitrogen is; rN2 k 3C AZO* ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) Fundamentals of Nonelementary Reaction…cont… Rate of formation of active intermediate = sum of the rates of formation of all reaction rAZO* rAZO*1 rAZO*2 rAZO*3 Where, rAZO*1 k1C 2 AZO rAZO*2 k 2 C AZO C AZO* rAZO*3 k 3C AZO* rAZO* k1C 2 AZO k 2 C AZO C AZO* k 3C AZO* The concentration of the active intermediate, AZO* is very difficult to measure because it is highly reactive and very short lived about 10 -9 s To express CAZO* in term of MEASURABLE CONC, we have to use STEADY STATE HYPOTHESIS (PSSH) ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) Pseudo-Steady-State Hypothesis (PSSH).. Its not possible to eliminate the concentration of active intermediate Active intermediate molecule has a very short lifetime because of its high reactivity (large specific reaction rates). Have to consider it present at very low concentrations Pseudo-Steady-State approximation The rate of formation = is assumed to be equal to its rate of disappearance. As a results, the net rate of formation of the active intermediate r* is ZERO Rate of formation of product, nitrogen; Rate of formation of AZO*; Using PSSH; r* 0 rN2 k 3C AZO* rAZO* k1C 2 AZO k 2 C AZO C AZO* k 3C AZO* rAZO* 0 rAZO* k1C 2 AZO k 2 C AZO C AZO* k 3C AZO* 0 ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) Pseudo-Steady-State Hypothesis (PSSH)cont.. rAZO* k1C 2 AZO k 2 C AZO C AZO* k 3C AZO* 0 k1C 2 AZO k 2 C AZO C AZO* k 3C AZO* 0 k1C 2 AZO C AZO* (k 2 C AZO k 3 ) 0 C AZO* k1C 2 AZO k 3 k 2 C AZO k 2 C AZO k3 At low conc azomethane; rN2 k1C 2 AZO rN2 k 3C AZO* 2 The final form of rate law rN2 2nd order k1 k 3C AZO k 3 k 2 C AZO At high conc azomethane; rN2 k 2 C AZO k3 1st order k1 k 3 C AZO k CAZO k2 ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) Pseudo-Steady-State Hypothesis (PSSH)cont.. Rules of Thumb For Development of Mechanism 1. Species having the conc(s) appearing in the denominator of the rate law probably collide with the active intermediate. A A* collision __ products 2. If a constant in the denominator, one of the reaction steps is probably the spontaneous decomposition of the active intermediate. A* decomposition __ products 3. Species having the conc(s) appearing in the numerator of the rate law probably produce the reac tan t A * other __ products active intermediate in one of the reaction step ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) Pseudo-Steady-State Hypothesis (PSSH)cont.. Exercise 1; Mechanism For Azomethane???? A A* collision __ products A* decomposition __ products reac tan t A * other __ products ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) Pseudo-Steady-State Hypothesis (PSSH)cont.. Ans; Mechanism For Azomethane A A* collision __ products AZO AZO* AZO AZO A* decomposition __ products reac tan t A * other __ products AZO* C2 H 6 N 2 AZO AZO AZO* AZO ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) Pseudo-Steady-State Hypothesis (PSSH)cont.. Exercise 2; By assuming the main product for the reaction below is ethane, write down the final form equation for rate of formation for ethane. CH 3 2 N 2 C2 H 6 N 2 Ans; rC2H6 k 3C AZO* rC2H6 ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) k1 k 3C 2 AZO k 3 k 2 C AZO Pseudo-Steady-State Hypothesis (PSSH)cont.. CHAIN REACTIONS Initiation………. Formation of an active intermediate Propagation / Chain Transfer………. Interaction of an active intermediate with the reactant/product to produce another active intermediate Termination………. Deactivation of the active intermediate ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) EXAMPLE 1; PSSH Applied to Thermal Cracking of Ethane (Gas-Phase Reaction) The thermal decomposition of ethane to ethylene, methane, butane and hydrogen is believed to proceed in the following sequence; Initiation; 1_ 2 6 C2 H 6 2CH 3 k C H Propagation ; k2 CH 3 C2 H 6 CH 4 C2 H 5 k3 C2 H 5 C2 H 4 H k4 H C2 H 6 C2 H 5 H 2 Termination ; r1 _ C2H6 k1 _ C2H6 C2 H 6 Lets _ k1 k1 _ C2H6 r2 _ C2H6 k 2 CH 3 C2 H 6 r3 _ C2H 4 k 3 C 2 H 5 r4 _ C2H6 k 4 H C2 H 6 r5 _ C2H5 k5 _ C2H5 C2 H 5 2 k5 2C 2 H 5 C4 H 1 0 Let _ k5 k5 _ C2H5 ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) EXAMPLE 1; PSSH Applied to Thermal Cracking of Ethane ….cont a)Use PSSH to derive a rate law for the RATE OF FORMATION OF ETHYLENE & RATE OF DISAPPEARANCE OF ETHANE…. Solutions…… Rate of formation of ethylene (Reaction 3) is, r3 _ C2H 4 k 3 C 2 H 5 k3 C2 H 5 C2 H 4 H Active intermediates : The net of reactions are: C2 H 5 C H : r CH 3 CH : r H 2 5 3 C2 H 5 CH3 H : r H r2C2H5 r3C2H5 r4C2H5 r5C2H5 0 r1CH3 r2CH3 2r1C2H6 r2C2H6 0 r3 H r4 H r3C2H 4 r4C2H6 0 ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) EXAMPLE 1; PSSH Applied to Thermal Cracking of Ethane ….cont From reaction stoichiometry, we have; r3C2H5 r3C2H4 r2C2H5 r2C2H6 C H : r r2C2H5 r3C2H5 r4C2H5 r5C2H5 0 C H : r r2C2H6 r3C2H 4 r4C2H6 r5C2H5 0 2 Then, r4C2H5 r4C2H6 2 5 C2 H 5 5 C2 H 5 Finally got C H : r CH : r 2 5 C2 H 5 3 CH3 H : r H r2C2H6 r3C2H 4 r4C2H6 r5C2H5 0 r1CH3 r2CH3 2r1C2H6 r2C2H6 0 r3 H r4 H r3C2H 4 r4C2H6 0 ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) EXAMPLE 1; PSSH Applied to Thermal Cracking of Ethane ….cont CH : r 3 CH3 r1CH3 r2CH3 2r1C2H6 r2C2H6 0 2r1C2H6 r2 C2H6 0 From substituting the concentrations into the elementary equation gives; 2k1 C2 H 6 k 2 CH 3 C2 H 6 0 Solving for the conc of the free radical CH , Where, r1 _ C2H6 k1 _ C2H6 C 2 H 6 r2 _ C2H6 k 2 CH 3 C2 H 6 3 2k1 CH 3 k2 ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) EXAMPLE 1; PSSH Applied to Thermal Cracking of Ethane ….cont Adding this 2 equations….. C H : r H : r 2 5 C2 H 5 H r2C2H6 r3C2H 4 r4C2H6 r5C2H5 0 r3 H r4 H r3C2H 4 r4C2H6 0 get… r2C2H6 r5C2H5 0 Substituting for conc in the rate laws….. k2 CH 3 C2 H 6 k5 C2 H 5 0 where… r2 _ C2H6 k 2 CH 3 C2 H 6 2 r5 _ C2H5 k5 _ C2H5 C2 H 5 2 ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) EXAMPLE 1; PSSH Applied to Thermal Cracking of Ethane ….cont PSSH solution….. from Solving for k2 CH 3 C2 H 6 k5 C2 H 5 0 2 C H gives us, 2 5 1/ 2 k2 C2 H 5 CH 3 C2 H 6 k5 1/ 2 2 k1 k 2 C2 H 5 C2 H 6 k 2 k5 where… 1/ 2 2k1 C2 H 5 C2 H 6 k5 ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) CH 2k 1 3 k2 EXAMPLE 1; PSSH Applied to Thermal Cracking of Ethane ….cont Substituting for C H in equation 2 5 r3 _ C2H 4 k 3 C 2 H 5 yields the rate of formation of ethylene; rC2H 4 2 k1 k 3 C 2 H 5 k 3 k5 1/ 2 C H 1/ 2 2 6 where… 1/ 2 2k1 C2 H 5 C2 H 6 k5 ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) EXAMPLE 1; PSSH Applied to Thermal Cracking of Ethane ….cont Next, we write the net rate of In terms of concentration, H : r H H formation in H : r r3 H r4 H r3C2H 4 r4C2H6 0 r3 H r4 H r3C2H 4 r4C2H6 0 r3C2H 4 r4 C2H6 0 k3 C2 H 5 k 4 H C2 H 6 0 1/ 2 Using eq H 2k1 C2 H 5 C2 H 6 k5 to substitute for where… r3 _ C2H 4 k 3 C 2 H 5 r4 _ C2H6 k 4 H C2 H 6 C H 2 5 conc of the hydrogen radical 1/ 2 2k k 3 1 C 2 H 6 k 4 H C 2 H 6 0 k 5 ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) gives the EXAMPLE 1; PSSH Applied to Thermal Cracking of Ethane ….cont from 1/ 2 2k k 3 1 C 2 H 6 k 4 H C 2 H 6 0 k 5 1/ 2 2k k 1 3 C2 H 6 k 4 H C2 H 6 0 k 5 H k3 k4 2k1 k 5 1/ 2 C H 1 / 2 2 6 ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) EXAMPLE 1; PSSH Applied to Thermal Cracking of Ethane ….cont Rate of disappearance of ethane is rC2H6 k1 _ C2H6 C2 H 6 k 2 CH 3 C2 H 6 k 4 H C2 H 6 Where, r1 _ C2H6 k1 _ C2H6 C 2 H 6 r2 _ C2H6 k 2 CH 3 C2 H 6 r4 _ C2H6 k 4 H C2 H 6 ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) EXAMPLE 1; PSSH Applied to Thermal Cracking of Ethane ….cont Substituting for the concentration of free radicals, the rate law of disappearance of ethane is…. rC2H6 k1 _ C2H6 C2 H 6 k 2 CH 3 C2 H 6 k 4 H C2 H 6 rC2H6 2k1 k3 k1 _ C2H6 C 2 H 6 k 2 C 2 H 6 k 4 k2 k4 rC2H6 2 k1 k1 2k1 C 2 H 6 k 3 k 5 1/ 2 Where, 2k1 k 5 1/ 2 C H C H 1 / 2 2 6 2 6 C H 1/ 2 2 6 CH 2k 1 3 k2 k 3 2k1 H k 4 k5 ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) 1/ 2 C H 1 / 2 2 6 Conclusions Reaction that not follow elementary rate law (NON ELEMENTARY involve a number of reaction steps, each of which is ELEMENTARY After finding net rates of reaction for each species, we use PSSH to derive a rate law of the reaction. PSSH not only can be used in gas-phase reaction, but also can be used in biological reactions (enzymatic reactions). ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) BIOLOGICAL REACTIONS •BIOREACTORS Lab Scale Bioreactor Industrial Scale Bioreactor ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) Fermentation Process ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) Major Functions of a Bioreactor 1) Provide operation free from contamination; 2) Maintain a specific temperature; 3) Provide adequate mixing and aeration; 4) Control the pH of the culture; 5) Allow monitoring and/or control of dissolved oxygen; 6) Allow feeding of nutrient solutions and reagents; 7) Provide access points for inoculation and sampling; 8) Minimize liquid loss from the vessel; 9) Facilitate the growth of a wide range of organisms. Ref;(Allman A.R., 1999: Fermentation Microbiology and Biotechnology) ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) Biotechnological Processes Of Growing Microorganisms In A Bioreactor 1) Batch culture: microorganisms are inoculated into a fixed volume of medium and as growth takes place nutrients are consumed and products of growth (biomass, metabolites) accumulate. 2) Semi-continuous: fed batch-gradual addition of concentrated nutrients so that the culture volume and product amount are increased (e.g. industrial production of baker’s yeast); Perfusion-addition of medium to the culture and withdrawal of an equal volume of used cell-free medium (e.g. animal cell cultivations). 3) Continuous: fresh medium is added to the bioreactor at the exponential phase of growth with a corresponding withdrawal of medium and cells. Cells will grow at a constant rate under a constant condition. ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) Biotechnological processes of growing microorganisms in a bioreactor ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) Batch Culture VS Continuous Culture Continuous systems: limited to single cell protein, ethanol productions, and some forms of waste-water treatment processes. Batch cultivation: the dominant form of industrial usage due to its many advantages. Ref;(Smith J.E, 1998: Biotechnology) ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) Advantages of Batch Culture VS Continuous Culture 1) 2) 3) 4) Products may be required only in a small quantities at any given time. Market needs may be intermittent. Shelf-life of certain products is short. High product concentration is required in broth for optimizing downstream processes. 5) Some metabolic products are produced only during the stationary phase of the growth cycle. 6) Instability of some production strains require their regular renewal. 7) Compared to continuous processes, the technical requirements for batch culture is much easier. ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) Fermentation Technology • What is it important to know the kinetics of the reaction in the fermenter? ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) Cell Growth Typical pattern of growth cycle during batch fermentation I. II. III. IV. V. VI. VII. VIII. Lag phase Acceleration phase Exponential (logarithmic) phase Deceleration phase Stationary phase Accelerated death phase Exponential death phase Survival phase From: EL-Mansi and Bryce (1999) Fermentation Microbiology and Biotechnology. ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) Cell Growth...cont... Lag Phase •Little increase in cell conc. •Cell adjusting their new environment, synthesizing enzymes & ready to reproducing Exponential Growth Phase •Cell are dividing at max rate •Cell able to use the nutrients most efficiently Stationary Phase •Cell reach a minimum biological space (lack of 1@> nutrients limits cell growth) •Net growth = 0 •Fermentation product produce. ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) Death Phase •Decrease in live cell conc occur. •Results of toxic byproduct Rate Laws Rate law for the cell growth rate of new cells, Cells + Substrate More Cells + Product The most commonly used expression is the Monod equation for exponential growth; rg Cc Where, rg cell _ growth _ rate( g / dm3 .s) specific _ growth _ rate( s 1 ) Cc cell _ concentration( g / dm3 ) ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) Rate Laws...cont... Specific cell growth rate can be expressed as, max Cs 1 ,s K s Cs Where, max a _ max_ specific _ growth _ reaction _ rate( s 1 ) K s the _ monod _ cons tan t ( g / dm3 ) C s substrate(nutrient)concentration( g / dm3 ) ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) Rate Laws...cont... Combine , rg Cc Will get, rg and max max C s Cc K s Cs max 1.3h 1 K s 2.2 X 10 5 mol / dm3 Cs , s 1 K s Cs Monod equation for bacterial cell growth rate Parameter value for the E.coli growth on glucose. Ks is small for a numb of different bacteria in which case the rate law reduce to, Plz refer ERT 104 Bioprocess Eng Principle rg max C c ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010) Thank You ERT 208/4 REACTION ENGINEERING SEM 2 (2009/2010)