Simmons_Jenny_SCChron

advertisement

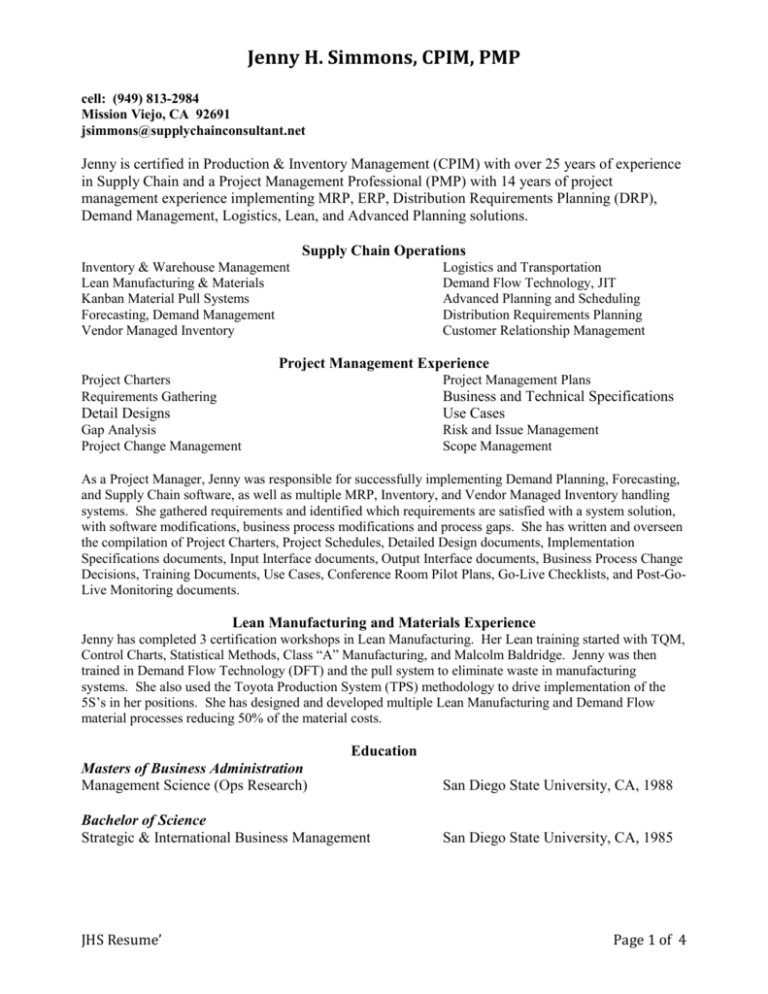

Jenny H. Simmons, CPIM, PMP cell: (949) 813-2984 Mission Viejo, CA 92691 jsimmons@supplychainconsultant.net Jenny is certified in Production & Inventory Management (CPIM) with over 25 years of experience in Supply Chain and a Project Management Professional (PMP) with 14 years of project management experience implementing MRP, ERP, Distribution Requirements Planning (DRP), Demand Management, Logistics, Lean, and Advanced Planning solutions. Supply Chain Operations Inventory & Warehouse Management Lean Manufacturing & Materials Kanban Material Pull Systems Forecasting, Demand Management Vendor Managed Inventory Logistics and Transportation Demand Flow Technology, JIT Advanced Planning and Scheduling Distribution Requirements Planning Customer Relationship Management Project Management Experience Project Charters Requirements Gathering Project Management Plans Detail Designs Business and Technical Specifications Use Cases Gap Analysis Project Change Management Risk and Issue Management Scope Management As a Project Manager, Jenny was responsible for successfully implementing Demand Planning, Forecasting, and Supply Chain software, as well as multiple MRP, Inventory, and Vendor Managed Inventory handling systems. She gathered requirements and identified which requirements are satisfied with a system solution, with software modifications, business process modifications and process gaps. She has written and overseen the compilation of Project Charters, Project Schedules, Detailed Design documents, Implementation Specifications documents, Input Interface documents, Output Interface documents, Business Process Change Decisions, Training Documents, Use Cases, Conference Room Pilot Plans, Go-Live Checklists, and Post-GoLive Monitoring documents. Lean Manufacturing and Materials Experience Jenny has completed 3 certification workshops in Lean Manufacturing. Her Lean training started with TQM, Control Charts, Statistical Methods, Class “A” Manufacturing, and Malcolm Baldridge. Jenny was then trained in Demand Flow Technology (DFT) and the pull system to eliminate waste in manufacturing systems. She also used the Toyota Production System (TPS) methodology to drive implementation of the 5S’s in her positions. She has designed and developed multiple Lean Manufacturing and Demand Flow material processes reducing 50% of the material costs. Education Masters of Business Administration Management Science (Ops Research) San Diego State University, CA, 1988 Bachelor of Science Strategic & International Business Management San Diego State University, CA, 1985 JHS Resume’ Page 1 of 4 Jenny H. Simmons, CPIM, PMP Certifications PMP, Project Management Professional, June 2013 CPIM, Certified in Production an Inventory Management, 1998 i2 Factory Planner Implementer, i2 Technologies, 1997 Demand Flow/JcIT Implementer, John Costanza Institute of Technology, 1988 and 1995 Professional Work Experience Simmons Consulting LLC Supply Chain Business Consulting 2011 - present Project: An International Compressor Manufacturer, CA and Canada Systems ERP Manufacturing Expert 1/2015- 9/2015 Project Manager for a reimplementation in Canada operations She managed the project to gather 260 GAPS, scheduled the project in Microsoft Project, ran Project Leadership meetings and Project Team meetings. Coordinated a revamp of all training documents for the business to include business process flows. Developed a training matrix and survey for user assessment of training gaps. Project: A Biotech Medical Device Manufacturer, Irvine, CA (Partnered with another Consulting Firm) Business Analyst, JDE 9.1.3 and 9.0 Manufacturing, Procurement 3/2014 – 12/2014 B.A. for 2 JDE upgrade projects in 2 Minnesota plants She gathered system configuration needs, modified system and workflow screens, unit tested, developed test scripts and test cases, and trained users in the new system functions. Project: A Food Distributor for Fast Food Retailers, City of Industry, CA (Partnered with another Consulting Firm) Project Manager 9/2013 – 1/2014 Project Manager for a 9.1.3 JDE software upgrade. She managed the budgets for the $350K software upgrade, resource allocations, project plans in Innotas and MS Project, hardware environment preparations, and outsourced supporting resources. Project: A Large Heavy Equipment Construction Manufacturer, Mossville, IL (Partnered with another Consulting Firm) Project Manager 9/2012 – 9/2013 Business Analyst for a $70M - $100M initiative to develop a consolidated view of requirements and supplier commitments for Global Purchasing. Jenny was instrumental in helping streamlining the overall solution to a plan that decreases the overall program initiative from 5 years to 3 years and reduces the plan from a $100M to a $50M - $70M solution. JHS Resume’ Page 2 of 4 Jenny H. Simmons, CPIM, PMP Project: A Life Sciences Company, Carlsbad, CA (Partnered with another Consulting Firm) Business Analyst 2/2012 – 6/2012 Jenny analyzed business shipment data to help develop an effective roll-out solution which recommended a significant project cost savings of 40% and a 50% reduction in implementation time. Project: A Motorcycle Specialty Retail Shop, Mission Viejo, CA Business Analyst 1/2011 – 4/2013 Analyzed proposed business processes to take customer internet sales, through inventory replenishment, order processing, to shipment then implemented it with the company’s website, zero inventory management practice, and vendor drop ship notifications. BackyardView Inc., Mission Viejo, CA 2006 – 2010 President Jenny created a unique visual consumer good for the business, restaurant, medical and personal home and designed production line and production processes that incorporated lean manufacturing principles for cost savings. Utilized HTML, performed search engine optimization and established internet marketing practices for the online business. Edwards Lifesciences, Irvine, CA 2002 - 2006 Global Supply Chain Systems, Project Manager Planning, Logistics, Global Supply Chain, Distribution Requirements Planning Led the implementation of the Advanced Planning system for the total Global Supply Chain group and was responsible for setting up forecasting and global supply chain planning for Distribution Requirements Planning. Led the establishment, setup and implementation of the global finished goods forecasting, planning, and distribution center replenishment. Inforte Corporation, Irvine, CA 2000 - 2002 Senior Project Manager, Supply Chain Project Manager and Supply Chain Business Analyst for Supply Chain implementations, business process modifications and process gaps. EDS, Electronic Data Systems, Plano, TX 1998 – 2000 Senior Supply Chain Manager Jenny led a multi-project, 80 person implementation of i2 Supply Chain Planner, Oracle Manufacturing, i2 Demand Planner, and i2 Sequence Planner in General Motors. Grant Thornton LLP, Dallas, TX 06/1997 - 8/1998 Supply Chain Project Manager Jenny led multi-system, multi-functional implementations at various companies from heavy equipment, high tech to consumer products. JHS Resume’ Page 3 of 4 Jenny H. Simmons, CPIM, PMP Supply Chain Operations 1984 to 1997 Jenny developed, implemented, and instructed back-flush and lean manufacturing material handling systems. She setup a floor stock replenishment system which significantly reducing production cycle time. This became the standard for Applied Materials. Jenny developed J.I.T. operations: BOM complexity reduction, resupply designs, production flow improvements and kanban implementation. Applied Materials: Jenny led the Material Prep Center creation with all new job procedures, visual shipment management, resupply process to production flow every 2 hours using visual management and kanban pulls, flattened BOMs for Module Manufacturing, increased ECN changes to minutes, defect alerting through poker chip use in bins, supplier kanban replenishment system with faxes and physical management, optimized kanban setup and management for small to very large expensive products, kanban establishment/handling for lot traceability, design recycle packaging for large items during intercompany shipment, redesigning work cells and Material Handling to support the work cells, and much more. BP Chemicals, Stockton: Jenny was instrumental setting up kanban and replenishment processes for 777 Blocker Door production, back-flushing setup and system established with typical MRP system, BOM flattening to 2 levels from 8, lean Master Scheduling established for lean processes, reduction of production structure resulted in an 80% reduction in Production Planning department resulting in a cost savings of $212,000, and more. BP Chemicals, Santa Ana: Created configurable products which eliminated 800 parts and decreased inventory, restructured forecasting on the component level to reduce schedule fluctuation, streamlined inventory and shipping operations to increase efficiency. Puritan-Bennett: Implemented DFT for the production line with back-flushing for production lines, created a re-usable packaging for reverse engineering circuit boards to the field, and more. Applied Materials Inc., Austin, TX B.P. Chemicals, Stockton & Santa Ana plants, CA Puritan-Bennett, Carlsbad, CA JHS Resume’ Logistics Manager, Mod Mfg IC/PC Manager P5000 Production Planning Manager Program Planner Page 4 of 4