What is System Safety?

advertisement

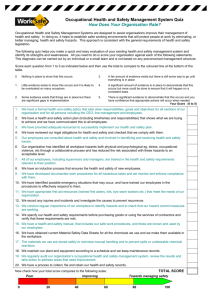

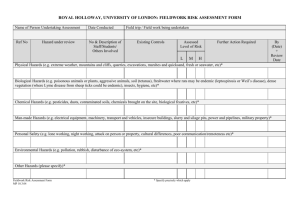

WHAT IS SYSTEM SAFETY? The field of safety analysis in which systems are evaluated using a number of different techniques to improve safety. There are a variety of techniques each designed to examine a particular aspect of a system with regards to safety. HOW DOES SYSTEM SAFETY IMPROVE SAFETY? System safety improves safety by: • Identifying unsafe parts of a system • Identifying unsafe steps in a procedure • Identifying changes or improvements that could be made to a system WHERE IS SYSTEM SAFETY USED? System safety techniques are used in virtually any field and type of company. At the more complex end of system safety, systems in the space shuttle are evaluated to determine if the space shuttle will work in a reliable and safe manner. System safety could be a simple as analyzing the steps necessary to perform a task. THE GOAL OF SYSTEM SAFETY Hazards are known and controlled to an acceptable level. Your priority. • Eliminate or control hazards. • Reduce the potential for accidents and losses. THE SYSTEM SAFETY PROCESS Identify each component and operational procedure. Identify and analyze potential hazards for each component. Eliminate the hazards by design, minimize effects, revise operating procedures. • Acceptable risks are judgments made by people responsible for making them (management). SYSTEM LIFECYCLE Based off of the MIL Standards • • • • • Concept Definition phase Development and test phase Production phase Operation phase Disposal CONCEPT DEFINITION PHASE • Basic System is roughly designed • Overall system goals and objectives are defined • Develop System Safety Program Plan DEFINITION PHASE • Preliminary design • PHA • SSHA • FTA • FMEA • HAZOP DEVELOPMENT AND TEST PHASE • • • • • Preliminary design Detailed designs Critical design review System testing Go/no go decision PRODUCTION PHASE • Product approved for production • Training • Equipment operators • O & SHA (operating & support hazard analysis) OPERATION PHASE • Product becomes operational • Safe system operation and maintenance DISPOSAL PHASE • Disposal procedures PREVENTION THROUGH DESIGN Addresses occupational safety and health needs in the design and redesign processes to prevent or minimize work related hazards and risks associated with the manufacture, use, maintenance and disposal of facilities, materials, and equipment. SAFETY THROUGH DESIGN Integration of hazard analyses and risk assessment methods into the early design and redesign processes. Taking actions necessary to so risks are at an acceptable level. ANSI/ASSE Z590.32011 Prevention Through Design: Guidelines for Addressing Occupational Hazards and Risks in Design and Redesign Processes was approved and went into effect in January 2012. ANSI/ASSE Z590.3-2011 provides guidance on including prevention through design concepts within an occupational safety and health management system. SYSTEMS TECHNIQUES There are numerous systems techniques available. Each has a purpose and an expected analysis outcome. • • • • • • Fault Tree Analysis Failure Mode and Effects Analysis HAZOP What If Analysis THERP MORT RISK PROBABLE LOSSES OVER A SPECIFIED TIME PERIOD COMPRISED OF THE FOLLOWING: • EXPECTED LOSS PER MISHAP • ANTICIPATED MISHAP RATE • EXPOSURE TO THE MISHAP RISK INDEXES MISHAP RATE • NUMBER OF MISHAPS PER UNIT OF EXPOSURE LOSS FROM EXPOSURE • MEASURED IN DOLLARS RISK INDEX = RATE x LOSS RANK BY INDEXES • LARGEST RISK INDEX GETS RANKED FIRST PRIORITIZING RISKS PROBABILITY SEVERITY CAN BE: • QUALITATIVE • QUANTITATIVE