car dismantler powerpoint - robert green equipment sales ltd.

advertisement

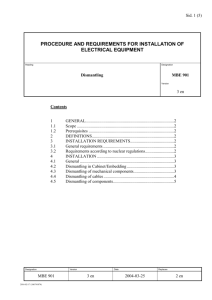

Introducing Kobelco Car Dismantling Machine INDEX Advantage of Car Dismantling Machine Product introduction End of Life Vehicle (ELV) & Engine Dismantling Demonstration Advantages of Car Dismantling Machine Advantages of Car Dismantling Machine • Work Can Performed by One Machine • The Machine Can Work Anywhere The machine is powered by Diesel fuel and so can operate anywhere on the site • Operators Safety Operators inside cabin protected by safety guard, 10-15 feet away from the work being dismantled. • Benefit from Mass Production, Excavators The major structures and componetns are the same as Kobelco’s standard hydraulic excavators, of which are produced more than 20,000 units annually worldwide. This brings low production cost and availability of service, parts and consumables. • Manual Operation Controlled manually by human operator depending on various types, models and conditions of ELV. Advantages of Car Dismantling Machine Advantages of Car Dismantling Machine Wholesale Value of Recycled Components These values are for examples only and will vary by market and destination as of 9-1-2014 Advantages of Car Dismantling Machine Product Introduction First Car dismantling Machine in the world “Nibbler” developed Lower clamp Arms developed and installed to stabilize the vehicle. 10 First Car dismantling Machine in the world Open & Close Grips & Teeth Bowl-shaped grip Cutting teeth Car dismantling machine is for efficiently dismantling and sorting vehicles & engines NOT A Conversion Kit Machine Kobelco designed and produced specifically for the Scrap Industry Crude add on SAS fork conversion. Fixed up and down clamp arms and crude Grip Assembly Use of Car Dismantling Machine Disposal of End-of-life Vehicle & Metal parts Dismantling Work 【 Main use 】 • Dismantling vehicles, and • removing and sorting their component recyclable parts Introduction of nibbler KVE720PR Multi-dismantling nibbler KVE720PR ・Shaped to handle all types of metal products ・Long and thin tips designed to secure a firm hold of small parts such as harnesses and electrical fittings ・Full rotating head that simplifies precision work that uses two rotation motors for maximum twisting torque. Lower Clamp Arm Cutting teeth Bowl-shaped grip Front Anvils Operation guide Nibbler rotating S/W Clamp arm UP & Down S/W Nibbler opening S/W Clamp arm Open & Close S/W Main Specifications End of Vehicle Life (ELV) and Engine Dismantling Demonstration Recycling Flowchart (Scrapping to Dismantling) Sorting of scrapped vehicles Recovery of interior/ exterior used parts Scrap car Car with recoverable parts Scrap car dismantling Functional parts recovery • Engine • Suspension and other parts Scrap recovery • • • • • Gas tank Suspension Muffler Other steel Engine Pre-sorting for recovery of valuable items • Air bag processing • Batteries • Air condition gas recovery • Fuel recovery • Oil recovery • Tire recovery • LLC recovery Non-metallic/ Plastic recovery Non-metallic recovery • • • • • • Radiator Condenser Blower fan Heater core Wiring harnesses Motors ELV Dismantling 21 Breakdown of Collectable and Recyclable Resources (1/4) Front & rear bumper : Resin Bumper, Interior and exterior parts Radiator : Copper, aluminum Brass, aluminum products Battery : Lead, sulfuric acid Battery Breakdown of Recoverable and Recyclable Resources (2/4) Suspension : Steel, aluminum Steel products, aluminum products Gear oil : Oil Alternative fuel for boilers and incinerators Transmission : Steel, aluminum Car parts, other steel products, aluminum products Breakdown of Recoverable and Recyclable Resources (3/4) Catalyst : Platinum, palladium Catalyst Window : Glass Glass wool, aggregate Door : Steel Car parts, other steel products Body : Steel Car parts, other steel products Breakdown of Recoverable and Recyclable Resources (4/4) Wheel : Steel, aluminum Car parts, aluminum products Tires : Rubber fuel, pavement material Seat : Urethane form, fibers Soundproofing materials for vehicles ELV Dismantling Hood removal Vehicle held by clamp arm 26 ELV Dismantling Side chassis frame removed 27 ELV Dismantling Lights removed Electric wire and harness removed by fork pointed tooth 28 ELV Dismantling Electric wire and harness pulled out from the front Radiator removed 29 ELV Dismantling Wiper motor removed Bumper taken off 30 ELV Dismantling Windshield taken out 31 ELV Dismantling Steering wheel and dashboard panel removed Panel separated by anvils on the clamp arms 32 ELV Dismantling Roof pulled off Lining materials peeled 33 ELV Dismantling Electric wire and harness under seats pulled off Seats taken out 34 ELV Dismantling Window mechanisms in doors removed Door lining material pulled off 35 ELV Dismantling Car body turned upside down 36 ELV Dismantling Cover removed Car body secured in clamp arm 37 ELV Dismantling Catalyst removed Muffler pulled out 38 ELV Dismantling Frame sections removed Suspensions removed 39 ELV Dismantling Main frame opened Oil drained and gas drawn off from shock absorbers 40 ELV Dismantling Engine removed 41 ELV Dismantling Fuel tank removed Rear suspension removed 42 Engine Dismantling 43 Engine Recoverable and Recyclable Resources Carburetor / Injection system: Recycled ・Engine : Steel, aluminum Car parts, other steel products, aluminum products ・Wire harness (copper) Copper products Starter motor : Recycled Engine oil : Oil Alternative fuel for boilers and incinerators Engine Dismantling Engine firmly secured by bowlshaped grips of clamp arm Hoses, tubes, electric wire and harness removed 45 Engine Dismantling Alternator removed A/C Compressor 46 Starter Engine Dismantling Transmission block separated from engine body 47 Use of Cutters to Remove Cylinder Head Engine Dismantling Remaining electric wire and harness and pipes removed 49 Engine Dismantling Video 50 THANK YOU