11 2015 Teaching Prestressed Miller

advertisement

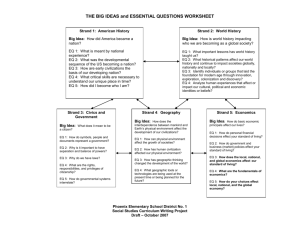

TEACHING PRESTRESSED CONCRETE DESIGN RICHARD A. MILLER, FPCI PROFESSOR OF CIVIL ENGINEERING UNIVERSITY OF CINCINNATI CHAIR, PCI R&D COUNCIL 1 WHY TEACH PS CONCRETE? • Code is now “unified”. PS and RC are treated basically the same. • PS heavily used in bridges. • PS heavily used in structures – especially – Parking garages – Slabs – Small industrial/commercial – Panels 2 MAJOR DIFFERENCES BETWEEN PRESTRESSED AND RC • Load Factors: – The same for RC and PS • Analysis – PS is often easier as many PS structures are precast and are analyzed as simple spans. – RC and Post Tensioned tend to be continuous. – Due to prestressing, PS structures experience additional creep deformations which may affect load distributions. 3 MAJOR DIFFERENCES BETWEEN PRESTRESSED AND RC • Flexure – Service load • Service load stresses must be considered with PS at two states – Release of prestressing – Service loads • RC - only service load deflection is checked. – Ultimate • Basically the same (stress block) • Must calculate the stress in the PS steel. 4 MAJOR DIFFERENCES BETWEEN PRESTRESSED AND RC • Shear – ACI shear calculation for CONCRETE contribution in PS is completely different. • Vci and Vcw– Flexural and Web Shear Capacity • Vc – Combined Shear Capacity – Stirrup contribution is the same for RC and PS. 5 MAJOR DIFFERENCES BETWEEN PRESTRESSED AND RC – AASHTO LRFD uses Modified Compression Field Theory for both RC and PS. • As an alternate, AASHTO now allows the Vcw Vci method, used in ACI 318, to be used for PS concrete. This was the method used in the old Standard Specs. Will probably be removed in next edition of AASHTO. • AASHTO allows the simplified 2√fc’ for RC. 6 MAJOR DIFFERENCES BETWEEN PRESTRESSED AND RC • Torsion – ACI: can use same method for RC and PS. • Some formulae modified for PS members. • Not particularly accurate for PS Concrete – ACI: permits the use of the PCI method for PS concrete. • Found in the PCI Design Handbook. – AASHTO: Modified Compression Field Theory for both PS and RC 7 MAJOR DIFFERENCES BETWEEN PRESTRESSED AND RC • Bond/Development length – Equations for development of non prestressed steel are not changed by the presence of prestressing steel. – Separate equations for development length of prestressed strand or bar. • Loss of prestressing force – Unique to PS concrete. 8 MAJOR DIFFERENCES BETWEEN PRESTRESSED AND RC • Deflections – PS structures are usually uncracked under service loads, so deflections are easier. – Must account for camber due to prestressing – Must account for creep deformations caused by prestressing. – If the PS beam cracks, deflection is calculated using a bilinear function. 9 NICE DEMONSTRATION “Unreinforced” Concrete Foam block Prestressed Concrete! Add rubber band! Even holds load! 10 There are two ways to prestress: Pretensioning Post-tensioning 11 PRETENSIONING 12 PRETENSIONING • Pretensioning: – Uses a bed. – Strand is tensioned first. – Concrete is cast around the strand. – Strand is cut, transferring prestressing force by bond. – Some prestressing force is lost because the concrete shortens under load and the strand shortens along with it. 13 14 15 16 POST TENSIONED 17 POST-TENSIONING • Post-tensioning – No bed is required. – Concrete is cast with ducts. – Strand or bar is placed in the ducts. – Strand or bar is tensioned by jacking against the concrete. This requires plates to spread jacking forces. • May be jacked from one or both ends. – Strand/bar is anchored. – Loss due to shortening is less than pretensioning. There is additional loss due to friction. 18 POST-TENSIONING • Bonded – The PT bars/strands are tensioned and the PT ducts are filled with grout. – Protects against corrosion • Unbonded – The PT bars/strands are tensioned and the PT ducts are NOT filled with grout. 19 Laterally post-tensioned box beam bridge 20 Grout tubes Post Tensioning jack 21 POST-TENSIONING VS. PRETENSIONING • Pretensioned members are usually used as simple spans or “continuous for live load” – Spans are set as simple then connected into a continuous structure. Loads applied before connection are taken as simple span; after connection loads are taken as continuous. • Post-tensioned structures may be simple or, more often, continuous. – In PT continuous structures, PT force causes “secondary moments”. 22 POST-TENSIONING VS. PRETENSIONING • In pretensioned elements, the prestressing steel is all or part of the primary load resisting mechanism. • In post-tensioned structures: – The PT steel is often part of the primary load resisting mechanism. – In some applications, PT is used for other purposes: • PT concrete boxes laterally to improve load distribution and prevent joint cracking. 23 POST-TENSIONING VS. PRETENSIONING • At transfer of prestressing force: – Different allowable stresses for compression in the concrete and tension steel. – Limits on stresses in the concrete due to anchorage devices in PT. • At service loads – no difference • At ultimate load – A different formula is used for fps for unbonded vs. unbonded steel. – Otherwise, no difference. 24 POST-TENSIONING VS. PRETENSIONING • Shear design is the same • Torsion design is the same. • Bond and development length: – Differences between pre- and post-tensioning. – For PT, tendons may be unbonded. – For pretensioned members, must account for “transfer length” – the length it takes for the prestressing force to be transferred by bond. 25 POST-TENSIONING VS. PRETENSIONING • Losses – Elastic Shortening is different – There is a friction loss and an anchorage loss for PT – Creep and shrinkage losses are the same. – Relaxation losses are based on the steel used. 26 A BASIC COURSE ON PS • It is NOT necessary to require RC as a prerequisite. – For a basic course, there is a limited amount of overlap. – If a student has taken RC, 80% of the course will be new material. – Students who have not taken RC should be able to pick up the common material. – Strength of Materials and Structural Analysis would be the only prerequisites. 27 A BASIC COURSE ON PS • Two options – Spend the entire course on prestressed concrete for buildings – Divide the course ½ buildings and ½ bridges. • For some students, this may be the ONLY exposure they get to bridge design. • One way to teach is to teach pretensioned first, then teach post-tensioned. – For post-tensioned, it would only be necessary to cover differences in detail. 28 A BASIC COURSE ON PS • A basic course covers flexure. • Flexure is the most common usage. • There is enough subject matter to fill an entire course and then some. – Beams • Non-composite vs. composite • Straight vs. deflected strand – Slabs/Hollowcore 29 A BASIC COURSE ON PS SUBJECTS • Introduction to prestressing – Uses – Fabrication • Materials – Concrete • Properties at application of prestressing • Long term – Prestressing steel – Hardware (inserts/chucks/jacks) 30 A BASIC COURSE ON PS SUBJECTS • Basic concepts of prestressing – how it works • Release/Application of Prestress – Top tension • Control with mild steel • Deflected/Harped strands • Debonded strand (pretensioned) – Bottom compression • Service load behavior – Loss of prestress – Service level stresses 31 A BASIC COURSE ON PS SUBJECTS • Ultimate Strength – Load Combinations – Stress in Steel – Tension Control • Minimum Reinforcement – Cracking moment • Shear • Deflection/Camber 32 RESOURCES • PCI Design Handbook – Sold at reduced cost to students (7th Ed) • CD’s $25 with (free) student membership • Hard Copy at member rate – Professors can usually get free copy from PCI Chapters • PCI Image Library – Great pictures to illustrate the point 33 RESOURCES • PCI Bridge Design Manual – Free copy to professor with permission to duplicate some sections – It is completely electronic! – Updated in 2011. – Contact William Nickas at PCI for more information. 34 PRESTRESSED IN A BOX A GREAT RESOURCE - READY MADE CLASS! • Most professors do not have time to create a new class. • Codes change and updating is real pain. • Most faculty members do not have access to some basic material PRESTRESSED IN A BOX IS THE ANSWER!!!!!! 35 PRESTRESSED IN A BOX A GREAT RESOURCE - READY MADE CLASS! • PCI teaches a one day seminar on basic prestressed concrete design. – Class is basically my notes from the UC PS course. – S. Brena from U Mass updated them. 36 PRESTRESSED IN A BOX A GREAT RESOURCE - READY MADE CLASS! • PCI changed their structural design seminar and had a lot of copies of the old (but still valid) seminar notes. • Bridge examples were available from PCI seminars. 37 PRESTRESSED IN A BOX A GREAT RESOURCE READY MADE CLASS! VERSION 2.0 IS UPDATED TO ACI-318-14!!!! 1.38 WHAT YOU GET • The basic one day “Introduction to Prestressed Concrete” seminar notes as PPT files. • The PCI Structural Design Seminar notes. – PPT files 39 WHAT YOU GET • Two Bridge Examples (Need updating) • Supporting Materials • The 7th Edition of the PCI Design Handbook. • Cost - $50 – We are hoping that Producer Members and Regional Directors will help with costs. 40 RULES FOR USE • Only not-for-profit institutions may use the material. • Institutions may only use the material for courses in a regular degree program. – May not be used for continuing education courses without PCI permission. • Institutions must protect the PCI Copyright. 41 RULES FOR USE • May post PDF versions of the notes on SECURE web sites. • Professor may modify the notes to correct errors or add ‘local’ material. • Basically – PCI wants to help professors, but they don’t want people making money off PCI work. 42 THE BASIC PS COURSE • Teaches through a design example. – 12RB28 beam is designed. – Three designs are available • Straight strand with top steel to control top tension. • Straight strand with top strand and debonded bottom strand to control top tension. • Harped strand to control top tension. – Complete design of the member – Back up calculations/spreadsheets are provided. – Background information and theory modules are provided. 43 THE BASIC PS COURSE – Introduction to Prestressing – Materials – Fabrication video – Applicable Code Provisions (ACI 318-14) – PCI Suggested Practices – Loads/load combinations • Factored Load Combinations • Advice on service load combinations (not in ACI). – Explanation of Classes U, T and C prestressed beams. 44 THE PS COURSE – Class U beam design. Choice of: • Straight strand • Top strand/bottom debonded strand • Harped Strand – Loss of prestressing calculation – Service load stresses (flexure) 45 THE PS COURSE – Release stresses and control of top tension – Ultimate flexural strength • Calculation of steel stress with approximate equation • Determination of and explanation of tension and compression control in PS. • Ductility Limit (Minimum steel requirement) 46 THE PS COURSE – Shear • Explanation of shear in concrete (compression field) • Vc equation • Vci and Vcw equations with derivation • Stirrup calculations – Development length/transfer length • Explanation of transfer length • Calculations – Bursting stirrups 47 THE PS COURSE – Camber/deflection • • • • Initial camber Growth in storage Long term camber PCI Camber Co-efficients – Design of a Class T beam • Existing design is modified for additional load and designed as Class T. 48 Sample slide Design the pretensioned interior 12RB28 beams Consider the structural system shown below: 49 All slides are updated to Sample slide PCI Design Handbook 7th edition. Calculate the self weight of the beam: From the PCI Handbook page 2-42 the section properties for a 12RB28 beam and strand pattern of 5 per row @ 2 inches. wsw = 350 plf 50 Sample slide Analysis calculations are provided. MOMENTS AND LOADS AT MIDSPAN TYPE MAGNITUDE MMIDSPAN Self Weight 350 plf 39.4 kft Slab Weight 980 plf 110.3 kft Live Load 2000 plf 225 kft Total 3330 plf 374.6 kft Note that the moment calculations are based on the center-tocenter span length of 30 feet rather than beam length of 32 feet. 51 Sample slide Calculate the number of strands: Recall that stress distribution in a generic prestressed concrete beam is as follows: 52 Basic prestressing equations are illustrated. Sample slide Calculate the number of strands: Assume that the prestressing tendons will be 3 inches from the bottom of the girder. Thus the eccentricity is: e = 14 in – 3 in = 11 in The MINIMUM prestressing force is (tension is negative): P Pey fcbl 7.5 fc ' A I P P(11 in)(14 in) 7.5 5000 psi 2.87 ksi ksi 336 in2 21952 in4 1000 P 234 kips Again, tension is negative. Thus the greater than sign is correct for negative numbers Note that P must be GREATER than 234 kips, so round the number of strands UP! 53 Sample slide Calculate the number of strands: As will be explained in the next section, over time prestressing strands lose force. This loss must be calculated, but it can’t be calculated at this time because the number of strands is not known. A loss of 20% is assumed. For 0.5 inch, Grade 270, low relaxation strand, initially stressed to 0.75 fpu, the stress per strand after loss is assumed as: kips Pstrand 0.75(270 ksi)(1.0 - 0.2)(0.153 in ) 24.8 strand P 234 kip # strand 9.44 strands Use 10 strands kip Pstrand 24.8 strand 2 54 Sample slide Loss of prestressing force – Total Loss: TL RE ES CR SH TL 3.31 ksi 16.6 ksi 20.5 ksi 5.24 ksi TL 45.6 ksi 45.6 ksi LOSS (100%) 22.5% 0.75(270 ksi) Initially the loss was assumed to be 20%, but 10 strands (rather than 9.44) were used. Try 10 strands to see if it works. fse Pi - TL 0.75(270 ksi) - 45.6 ksi 156.9 ksi Peff 10 strands(0. 153 in2 )(156.9 ksi) 240 kips 55 Graphic explanations are provided. Sample slide Development Length: It is assumed that the stress in the strand increases linearly over the transfer length from zero at the end of the beam to full effective stress at the end of the transfer length. 56 Sample slide The Excel file is provided. Transfer stress in a harped strand beam: Stress at Bottom 3 fallowable= 2.4 ksi 2.5 Stress (ksi) 2 1.5 1 0.5 0 0 4 8 12 16 20 24 28 32 Length (ft) A plot of the stress distribution along the length of the bottom of the beam is shown. The bottom of the beam is now OK 57 Sample slide Transfer stress in a harped strand beam: Stress at Top 0 0 -0.1 4 8 12 16 20 24 28 32 fallowable= 0.19 ksi Stress (ksi) -0.2 -0.3 -0.4 fallowable= 0.38 ksi -0.5 -0.6 -0.7 Length (ft) A plot of the stress distribution along the length of the top of the beam is shown. The top of the beam is generally overstressed, so add steel. 58 Sample slide Check service level stresses: The plot shows the service level stresses for the harped strand configuration. The stresses in the bottom of the beam are almost exactly the limit stresses. Harped Strands 2.5 Top – All loads 2.0 Stress (ksi) 1.5 1.0 Top – Dead loads 0.5 0.0 0 5 10 15 20 25 30 -0.5 Bottom – All loads -1.0 Length (ft) 59 EXCEL FILES PROVIDED • The original Excel files are provided. • They are not intended to be given to students, but can be if protected. • By looking at these files, instructors can see how the calculations are performed. • The original graphs are provided. – Can be modified to make additional points. • Instructors can make a copy of the Excel files and then use that as a basis for the new problems – Homework – Exams 60 Sample slide Check ultimate strength: For prestressed concrete, the definition of ultimate moment is exactly the same as for reinforced concrete. 61 Sample slide Check ultimate strength: fps γ p fpu d fpu 1 ρ p (ω - ω' ) β1 fc ' dp Valid only if f se 0.5fpu Handbook and Code references provided! PCI Design Handbook Section 4.2.1.6. ACI 20.3.2 62 Sample slide For the harped strand configuration, ignore the mild top steel (conservative): p 0.0051 f c ' 5000 psi 1 0.80 γ p 0.28 (low relaxation strand) γp f ps f pu 1 1 f pu p f ' c 0.28 270 ksi f ps (270 ksi)1 0.0051 244 ksi 5 ksi 0.80 63 Sample slide Find the capacity of the beam: Check ultimate strength: (1.53 in 2 )(244 ksi) a 7.32 in 0.85fc ' b (0.85)(5 ksi)(12 in) 7.32 in 2 Mn (1.53 in )(244 ksi)25 in 2 7967 kip in 664 kip ft A p fps ΦMn 0.9(664 kip ft) 597 kip ft The capacity at midspan length of the beam is 597 kip ft. 64 Sample slide 125 F Vcw 100 F Vci 75 Shear (k) F Vc 50 Vu 25 Center of Bearing Midspan 0 0 3 6 9 12 15 Length (ft) Comparing Vc with Vcw and Vci . 65 Sample slide Photos provided for clarification. Bursting stirrups : Additional stirrups are required at the end of the members to prevent bursting when the tendons are released. 66 Sample slide Camber : The equations of deflection for straight prestressing strands and self weight are: Due to self weight of the beam δ sw 5 wL4 384EciI Due to initial prestressi ng force δps ML2 Peff eL2 8EciI 8EciI Equations for deflection (camber) are found in the appendix of the PCI Design Handbook. 67 Sample slide The situation is a little different when strands are harped. The equation used for harped strands is: Equations for various cases of P0 e eL P0 e' L2 a 2 deflected strand are found in the appendix of the PCI Design 8EciI EciI 8 6 Handbook. Where : P0 is the initial pull of the prestressi ng 2 e e is the eccentrici ty at midspan e' is the eccentrici ty at the end L is the length of the beam a is the distance from the end to the harp point Eci is the initial modulus of elasticity I is the moment of inertia of the beam 68 PRESTRESSED IN A BOX • Bridge design examples – Single span prestressed box. – Middle span, interior girder of a continuous for Live Load Girder. • Information on this in the Bridge part of this seminar. 69 SUMMARY • Prestressed concrete is widely used. It should be given the same importance as reinforced concrete or steel design in the curriculum. • Prestressed concrete can be taught as a separate course or as part of an RC course. – If taught as part of an RC course, it can be a separate module, or it can be integrated into the RC course. 70 SUMMARY • Subjects to teach are: – Materials/Fabrication – Loads/Load Factors – Flexure • • • • Release Service (includes loss of prestressing force) Ultimate strength Minimum reinforcing – Shear – Development length 71 SUMMARY • Additional subjects – Torsion – Composite structures – Camber and deflection – Nonlinear deflection/Class “T” members. 72 Available to you! • PRESTRESSED IN A BOX • CLASS NOTES (ACI 318-14!) – BASIC THEORY – BUILDING EXAMPLES – BRIDGE EXAMPLES • BACK UP SPREADSHEETS! • PCI DESIGN MANUAL! • PCI STRUCTURAL SEMINAR! 73