Combat Propulsion Systems - L

advertisement

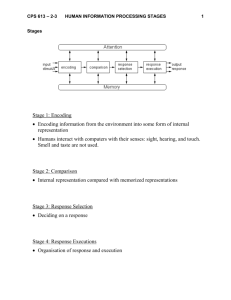

Combat Propulsion Systems L-3 CPS Supplier Information Package 10 August 2015 History of Changes Combat Propulsion Systems Revision Number Revision Date Summary of Changes - 10 August 2015 Initial Release A 5 October 2015 Slides 15, 20, 21, 23, 25, 28, 29, 33, 35,37, 38, 42. Hyperlink to Inspection Request form updated throughout document. New EIDP slide added. Power & Propulsion Systems We Power Freedom L-3 Proprietary 2 Welcome to Combat Propulsion Systems… Combat Propulsion Systems Presentation Outline L-3 CPS Customer Base L-3 CPS Supplier Expectations L-3 CPS Vision, Mission and Value L-3 CPS Quality Policy L-3 Ethics Reporting Reps and Certs requirements RFQ & PO requirements Procurement Terms and Conditions Counterfeit Parts Risk Mitigation Shipping & Receiving Procurement and Quality Webpage’s Strategy for Supplier Improvement Supplier Minimum Quality System Requirements Supplier Rating System Supplier Performance Management Procurement and Quality Clauses Archive Clauses & FAQ Inspection Delegation Stamp Program Certified Supplier Program Preferred Supplier Program Visit our website: http://www2.l-3com.com/cps/index.html Supplier Corrective Action Request (SCAR) Supplier Quality Material Report (SQMR) Supplier Process Change Request (SPCR) First Piece Inspection First Article Inspection AS9102 Graded Fastener Requirements End Item Data Package (EIDP) Inspection and Sampling Plan L-3 CPS Acronyms Power & Propulsion Systems We Power Freedom L-3 Proprietary 3 L-3 CPS Customer Base Combat Propulsion Systems CPS’ Strong, Global Customer Base: Products, Applications, Spares, Support End-Use Customers • U.S. Government • U.S. Army • U.S.M.C. • International Customers CPS Major Products Vehicle Manufacturers • General Dynamics • BAE Systems • Lockheed Martin • Navistar • International OEMs Military Products, Spare Parts, Overhaul Kits • U.S. Government • U.S. Army • U.S.M.C. • Vehicle Manufacturers • International End-Users Power & Propulsion Systems We Power Freedom Tracked Vehicle Applications Wheeled Vehicle Applications Export Authorization / Licenses CPS is approved for product and technology export to over 18 countries L-3 Proprietary 4 L-3 CPS Supplier Expectations Combat Propulsion Systems The Supplier Information Package (SIP) has been developed to provide the processes and expectations of suppliers regarding quality systems and in meeting the terms of L-3 CPS purchasing agreement, engineering drawings and specifications Quality: Compliance to customer requirements Delivery: Meeting or exceeding schedule requirements Cost: Pricing containing reasonable profit margins with minimum total cost These 3 key performances indicators, in support of continual improvement efforts, will allow L-3 CPS and its suppliers to meet its customers' challenges. We recognize the value of having suppliers who are committed to providing quality goods and services in a timely manner. Power & Propulsion Systems We Power Freedom L-3 Proprietary 5 L-3 CPS Vision, Mission and Values Combat Propulsion Systems • Vision - To be the Manufacturing Center Of Excellence (MCOE) powering the Combat Arms of US and Allied Militaries • Mission - Through our Manufacturing Center Of Excellence, provide superior products, engineering, and support services exclusively to our defense customers • Values - One Team, Warfighter Focused, Committed to Quality, Accountability and Integrity Power & Propulsion Systems We Power Freedom L-3 Proprietary 6 L-3 CPS Quality Policy Combat Propulsion Systems L-3 Combat Propulsion Systems present and future Quality Management Systems goals are guided by the following objectives: • Ensuring our employees are properly trained so they are better able to serve our customers • Understanding, measuring and improving our process capability • Enabling a lean culture for continual improvement of our processes and system • Consistently meeting our customers expectations for product quality and performance Power & Propulsion Systems We Power Freedom L-3 Proprietary 7 L-3 Ethics Reporting Combat Propulsion Systems To raise questions or concerns regarding any known or suspected violations of applicable laws, regulations or ethics and business conduct, L-3 CPS has provided the following resources for reporting: – To report an ethics violation, please contact L-3 CPS Ethics Officer, Becky Hekkema Email: Rebecca.Hekkema@L-3com.com Direct Phone: (231)-724-2618 Power & Propulsion Systems We Power Freedom L-3 Proprietary 8 Reps and Certs Combat Propulsion Systems Suppliers who sell parts to a government contract are required by L-3 corporate to fill out the representations and certifications annually. Link to Reps & Certs: http://webs.l-3com.com/repsandcerts/tools/public.aspx Power & Propulsion Systems We Power Freedom L-3 Proprietary 9 RFQ & PO requirements Combat Propulsion Systems Quotes must be returned by the RFQ expiration date or they cannot be used. No exceptions. – An extension may be requested if the request is received by the buyer 24 hours prior to the expiration date. All purchase orders must be signed and acknowledged by suppliers. Power & Propulsion Systems We Power Freedom L-3 Proprietary 10 Procurement Terms and Conditions Combat Propulsion Systems Procurement Terms and Conditions are located on the Procurement webpage: http://www2.l-3com.com/cps/procurement.html Suppliers are responsible for meeting all Terms and Conditions flowed on the purchase order. Please contact your commodity buyer agent for exceptions. Power & Propulsion Systems We Power Freedom L-3 Proprietary 11 Counterfeit Parts Risk Mitigation Combat Propulsion Systems Counterfeit or suspect parts requirements are contained with the L-3 CPS Terms and Conditions flowed down from L-3 Corporate. – Reference CC008 – Supply Service Subcontract T&Cs Rev 12 Sections 4 New Materials; Packaging, Shipping, Markings – d&e Section 6 Rejection Section 16 Goods Warranty – a&b Power & Propulsion Systems We Power Freedom L-3 Proprietary 12 Shipping & Receiving Combat Propulsion Systems Dock hours: 7am to 11:15am & 12 Noon to 2:30pm Monday thru Friday Eastern Time For additional L-3 CPS Shipping & Receiving information, please contact: – Shipping: Dan Hilton (231) 724-2794 – Receiving: Greg Dominiak (231) 724-2606 Please reference the Procurement Terms and Conditions for the following information – – – – Packaging Instructions Transportation Routing instructions Packing slip requirements Wood Packaging requirements – Link to Terms and Conditions: http://www2.l-3com.com/cps/procurement.html Power & Propulsion Systems We Power Freedom L-3 Proprietary 13 Procurement & Quality Webpages Combat Propulsion Systems The Procurement webpage can be found at the L-3 CPS webpage located here: http://www2.l-3com.com/cps/procurement.html The Quality webpage can be found at the L-3 CPS webpage located here: http://www2.l-3com.com/cps/quality.html These webpages contain supplier applicable Terms & Conditions, Purchase Order (P.O) clauses, supply chain and quality processes, tools and forms. Please bookmark these pages. – Processes, tools and forms change frequently in a continual improvement environment. Always check for updates prior to submitting documentation. Supplier is responsible for doing business to the most current revision on all applicable contract requirements. Power & Propulsion Systems We Power Freedom L-3 Proprietary 14 Strategy for Supplier Improvement Combat Propulsion Systems Prevention (Building Quality In) – – – – – – – – Improved Q-clauses Commodity team structure Certified Suppliers Preferred Suppliers Delegated Suppliers Industry Certifications Supplier Audits Better Technical Documentation and Contractual Direction – Order quantities – Risk Mitigation Strategies Supply Chain Optimization 5% 15% Prevention Detection Corrective Action 80% Detection – Source Inspection – Receiving Inspection – FPI/FAI Corrective Action – Accountability for poor performance Power & Propulsion Systems We Power Freedom L-3 Proprietary 15 Supplier Minimum Quality System Requirements Combat Propulsion Systems The supplier shall develop, document, implement and maintain a quality system which ensures compliance to all purchasing agreement requirements. The quality system shall be compliant with ISO 9001:2008 (or latest version), AS9100, AS9120 , or another auditable quality system. ‘Approved’ supplier status is contingent upon successful completion and approval of an L-3 Self Survey and/or on-site qualification survey. Distributors and Special Processors may qualify under QMS questionnaires specific to the industry type. L-3 CPS Special Processors require an on-site survey for special process qualification. Special Processors with Nadcap accreditation should submit proof of certification with their supplier survey. Suppliers with a current certified Quality Management System to AS9100, ISO 9001, or AS9120 and undergo periodic audits by a 3rd party registrar should submit proof of certification with their supplier survey. Upon attaining L-3 CPS approval status, supplier may remit proof of QMS 3rd party registrar certification as part of L-3 CPS supplier reevaluation requirement in lieu of the L-3 Self Survey. The supplier's quality system is subject to periodic review by L-3 CPS and/or government agencies. These reviews may be reduced at the discretion of the L-3 CPS Supplier Quality Assurance Group. Power & Propulsion Systems We Power Freedom L-3 Proprietary 16 Supplier Minimum Quality System Requirements Combat Propulsion Systems Sub tier control: The supplier's quality system shall provide for control of purchases and services from sub tiers to include, but not limited to, conveyance of applicable contract and technical requirements, and a method of assessing sub tiers capability and performance to contract/technical requirements. Please submit a Supplier Process Change Request (SPCR) for approval of supplier process change that potentially affects fit, form or function. This form can be found on the L-3 CPS Quality webpage: http://www2.l-3com.com/cps/quality.html SPCR (Supplier Process Change Request) If you have questions on the SPCR form or process, contact your SQA commodity lead and commodity buyer agent. Once completed, email the form to both L-3 commodity representatives and DLCPS-SQA@L-3com.com. Power & Propulsion Systems We Power Freedom L-3 Proprietary 17 Supplier Rating System Combat Propulsion Systems L-3 CPS Supplier Rating system was revamped in January 2015. The new rating system takes into account more measurable areas of performance accountability. - Cost of Poor Quality - Risk of doing business - Responsiveness - Early/late penalty L-3 CPS has a minimum acceptable performance level of 90%. Power & Propulsion Systems We Power Freedom L-3 Proprietary 18 Supplier Rating System Combat Propulsion Systems Supplier scorecards are no longer auto-generated and sent to suppliers through the Quality Information System (QIS) TIPQA. This is a future implementation being worked internally. Please contact your SQA commodity lead for your most current Quality and Delivery ratings. Power & Propulsion Systems We Power Freedom L-3 Proprietary 19 Supplier Performance Management (SPM) Combat Propulsion Systems Supplier Performance Management (SPM) is an L-3 CPS Material Acquisition and Supplier Quality initiative which identifies, monitors, mentors and potentially eliminate critical suppliers who fail to maintain greater than 90% quality and/or delivery acceptance levels and/or have provided nonconforming material resulting in the issuance of a major severity level Supplier Corrective Action Request (SCAR). Suppliers with less than 90% quality and/or delivery ratings or are issued a SCAR are not automatically put on SPM. Further risk analysis may be required by the commodity team to identify the additional risk criteria for putting a supplier on SPM. Risk criteria considerations may include the severity of the nonconformance, systemic supplier performance issues, impact to customer/schedule, and failure criticality. Suppliers put on SPM will be issued a letter from the commodity buyer agent formally announcing placement onto SPM. If a supplier has delegate stamps, the supplier’s stamps may be revoked until improvements in quality and/or delivery performance ratings have occurred. Supplier Performance Management Placement Considerations for placement on SPM include current and historical quality and delivery performance, Supplier Corrective Action Requests (SCAR), Suppliers responsiveness and commitment to improvement by supplier management, terms of contract/purchase order(s), directed sources of supply, other factors considered appropriate to incorporate. Power & Propulsion Systems We Power Freedom L-3 Proprietary 20 Supplier Performance Management (SPM) Combat Propulsion Systems A supplier on Supplier Performance Management (SPM) shall not be awarded new purchase orders. Additional consequence of systemic performance problems can result in removal from the L-3 CPS Approved Supplier List (ASL). Power & Propulsion Systems We Power Freedom L-3 Proprietary 21 Procurement and Quality Clauses Combat Propulsion Systems L-3 CPS has established the Procurement and Quality Assurance requirements (Q Clauses) which are applicable as specified on the Purchase Order. As an L-3 CPS supplier, you are responsible for meeting the contractual requirements within the Quality Clauses. If you cannot meet a clause, please contact your commodity buyer agent prior to submitting the RFQ. L-3 CPS clauses have been updated. Always check for updates to clauses prior to submitting documentation. Supplier is responsible for doing business to the most current revision on all applicable contract requirements. Procurement clauses are located on the Procurement webpage located here: - http://www2.l-3com.com/cps/procurement.html Quality clauses are located on the Quality webpage located here: - http://www2.l-3com.com/cps/quality.html Power & Propulsion Systems We Power Freedom L-3 Proprietary 22 Archive Clauses & FAQ Combat Propulsion Systems L-3 CPS new Quality clauses were released on August 10, 2015. Existing purchase orders prior to this date are expected to fulfill existing contract requirements to the archived clauses. L-3 CPS archived clauses and PQA Handbook can be found on the Archive Clauses tab located on the L-3 CPS webpage. FAQ: Why do the old clauses say ‘superseded by’ on purchase orders? – Because of the volume of open purchase orders during the release, we could not delete the archive clauses from the system. Therefore, a cross reference matrix was created. However, if the purchase order you are currently working was issued before August 10, 2015, you are expected to fulfill contract requirements to the archived clauses. This also applies to purchase order supplements to P.O’s issued before August 10, 2015. Is Nadcap certification required if the P.O was issued before August 10, 2015? – No. While an archive clause on your purchase order supplement may now be superseded by QX3, this requirement did not exist before August 10, 2015. Only if you are working to a P.O issued after August 10, 2015 does the QX3 Nadcap Requirements apply. Power & Propulsion Systems We Power Freedom L-3 Proprietary 23 Inspection Delegation Stamp Program Combat Propulsion Systems L-3 CPS recognizes suppliers with high levels of performance and authorizes direct release of shipments to L-3 CPS via Inspection Delegates at the supplier’s facility. Suppliers who are interested in participating in the Inspection Delegation Stamp program should complete the following forms available on the L-3 CPS Quality website: http://www2.l-3com.com/cps/quality.html Required forms to be completed and submitted by email to your SQA commodity lead: - Inspection Delegation Stamp Request Form - Inspection Delegation Stamp Request Check Sheet Suppliers shall meet the following requirements for consideration into the Inspection Delegation Stamp Program. 1. Approved supplier shall have an active, consecutive performance history with L-3 CPS of no less than 12 months 2. Quality acceptance level of 95% across all part numbers delivered over a rolling 12 month period. 3. On-time delivery rating of 90% across all part numbers delivered over a rolling 12 month period. 4. Effective closure of any issued corrective actions Power & Propulsion Systems We Power Freedom L-3 Proprietary 24 Inspection Delegation Stamp Program Combat Propulsion Systems The supplier shall appoint qualified personnel to act as Inspection Delegates to perform acceptance inspection activities at their facility. L-3 CPS reserves the right to conduct audits at the Supplier Facilities at the discretion of L-3 CPS to ensure compliance to program guidelines. The supplier shall identify a qualified delegate(s) to perform acceptance activities at their facility. The delegate(s) must have Quality Assurance responsibility and be assigned to or have access to L-3 CPS P.O. and technical information. The delegate(s) selection must be based upon the following: 1. Technical competence 2. Quality Assurance background and experience 3. Unrestricted access to L-3 CPS SQA 4. Access to the manufacturing process for process verification 5. Ability to exercise the responsibility of the position as defined within this document (including a ‘No Ship’ directive) An L-3 CPS Inspection Stamp will be assigned to the approved delegate(s). This individual is responsible for ensuring proper usage and maintenance of the inspection stamp. L-3 CPS requests that the supplier have at least 2 delegate stamp holders in case of absence. Transfer or use of the L-3 CPS stamp by another individual is not allowable. In the event an Individual’s position as a delegate is terminated or position changes, L-3 CPS must be notified immediately. The delegate’s inspection stamp is to be returned to the L-3 CPS commodity lead. If lost, immediately notify Supplier Quality Assurance at L-3 CPS. No other form of acceptance on the shipper is allowed. Power & Propulsion Systems We Power Freedom L-3 Proprietary 25 Inspection Delegation Stamp Program Combat Propulsion Systems If L-3 CPS issued delegation stamps are revoked from a supplier due to nonconformance(s) or supplier performance, on-site source inspections may be required before shipment of product takes place. – Suppliers shall be responsible for all costs associated with source inspections performed at the suppliers facility. For consideration back into the Inspection Delegation Stamp program after stamps have been revoked due to performance problems, suppliers must complete the action plan implemented by the applicable commodity team. Supplier will need to re-apply for stamp delegation by submitting the required forms. Inspection delegate is responsible for assuring all requirements of the purchase order are satisfied for the documentation package; including stamping off shipping paperwork. – A copy of the stamped Shipper/Packing slip and all supporting inspection data and objective evidence of product conformance to contract requirements is to be maintained on file at the suppliers facility for seven (7) years after P.O completion. – These documents shall be made available for L-3 CPS and /or government review at any time as requested and kept on file as defined in your P.O Terms and Conditions. Please contact your SQA commodity lead or commodity buyer agent with any questions you may have regarding submitting the documentation requirements to your purchase order. Power & Propulsion Systems We Power Freedom L-3 Proprietary 26 Certified Supplier Program Combat Propulsion Systems L-3 CPS provides the opportunity for our special process suppliers to become certified. The Certified Supplier program was implemented to mitigate risk on parts that cannot be inspected or tested after build completion. About the Certification program: A supplier will be deemed “certified” when performance has been attained and maintained at such a level that typical levels of inspection and risk can be reduced or eliminated. Supplier certification is attained at the special process level. The commodity team may recommend a supplier to be considered for special process certification. The goal of the program is to reward suppliers who have attained repeatable and consistent process controls within their special processes and to certify individualized special processes. Attaining certified status: Supplier shall have an active, consecutive performance history with L-3 CPS of no less than 12 months. The following criteria shall be considered: – Quality – For a supplier certification a recommended acceptance level of 98% across all part numbers delivered over a rolling 12 month period. – No outstanding Supplier Corrective Actions over 12 months – Delegate stamp supplier status – Zero internal rejections and/or escapes over 12 months – Successful passing of on-site special process audit Power & Propulsion Systems We Power Freedom L-3 Proprietary 27 Certified Supplier Program Combat Propulsion Systems – Delivery – On-time delivery rating of 98% across all part numbers delivered over a rolling 12 month period. – No outstanding Supplier Corrective Actions over 12 months Additional qualification criteria for risk reduction consideration • AS Certification • ISO/TS Certification • Nadcap Certification • Performance of on-site physical surveys – Considerations for removal of certified status Repeat or past due Supplier Corrective Actions will disqualify the supplier from certified status. Loss of delegation stamp status. Loss of industry standard certification (QMS, Nadcap, etc…) Failure of on-site L-3 recertification survey – Reinstatement of Certified status In the event that status of Certified is terminated, it may be reinstated by one or a combination of 12 months of 98% performance ratings for Quality and Delivery, reinstatement of industry standard certification, successful closure of outstanding SCARs, no repeat SCAR issues and/or recertification survey approval. Power & Propulsion Systems We Power Freedom L-3 Proprietary 28 Preferred Supplier Program Combat Propulsion Systems Eligibility: – A supplier may be eligible for Preferred Supplier status if the supplier has: Performed as an L-3 Communications Supplier for a minimum of 24 months Annual contracts of $500,000 or greater Meets program objectives for ethics, quality, delivery, cost and responsiveness metrics for Quality and Delivery Evaluation Metrics: – Eligible suppliers will be accepted into the Preferred Supplier Program based on their achievement in five areas. The evaluation metrics are selected to measure the supplier’s total performance and value to our customers. Quality: Supplier has maintained a 98% across all part numbers over a rolling 12 month period. Timeliness: Supplier has maintained a 98% across all part numbers delivered over a rolling 12 month period Responsiveness: The supplier exhibits flexibility to address urgent needs, support rescheduling requests, and reacts to changes in requirements. Ethics: The supplier maintains an ethics program. Processes are in place to ensure a culture of compliance and business integrity. Cost: The supplier provides cost effective solutions to requirements and negotiates in good faith. Benefits: – Benefits to suppliers admitted to the PSP include: Communication of Preferred Supplier status via an L-3 CPS Intranet page with links to supplier’s company information Power & Propulsion Systems We Power Freedom L-3 Proprietary 29 Supplier Corrective Action Request (SCAR) Combat Propulsion Systems Supplier Corrective Action Requests (SCAR) are issued by the SQA commodity lead for Quality nonconformances or the procurement agent for Delivery nonconformances. Notification will be received by a TIPQA generated email. The L-3 CPS 7-D Corrective Action form, 5 Why’s Analysis tool, Fishbone Diagram tool and the corrective action training sheet are attached to the SCAR remitted through TIPQA. With exception of the training sheet, these are also available for download at the L-3 CPS Quality website: http://www2.l-3com.com/cps/quality.html 1. 2. 3. 7-D Corrective Action 5-Why’s Analysis Tool Fishbone Diagram Tool SCAR responses must be able to pass a 1st, 2nd, and/or 3rd party audit. Therefore, submitting a root cause analysis (RCA) tool used for determining root cause must be submitted with the SCAR in addition to all supporting documentation (pictures, processes, procedures, etc…) required for verification and SCAR approval. Suppliers should use either the 5 Why’s tool or the fishbone diagram for more complex nonconformance. If another RCA tool is preferred, please contact your SQA commodity lead for approval prior to continuation of SCAR completion. Effective corrective and preventive action cannot be properly assessed without evaluation of the root cause analysis. Power & Propulsion Systems We Power Freedom L-3 Proprietary 30 Supplier Corrective Action Request (SCAR) Combat Propulsion Systems SCAR submittal is required within 20 business days. If additional time is required to complete effective RCA and CAPA processes, an extension should be requested to your SQA commodity lead or commodity buyer agent no less than 24 hours before the original due date. Request does not imply consent. You must receive written authorization of approval from the L-3 CPS representative for extension consent. There is a strict 3 date extension maximum with very limited exceptions considered. Containment is required within 24 hours at the supplier and/or sub tier. Definitions of severity levels for SCARS: 1. Major nonconformance: A nonconformance that would result in the shipment of a nonconforming product. Conditions that may result in the failure of or materially reduce the usability of the products or services for their intended purpose. 1. Examples: Systemic trend of part failure, assembly downtime, customer/schedule impact, critical failure (may not be systemic). 2. Minor nonconformance: A nonconformance that would result from a failure to conform to a specified requirement. 1. Examples: One-off occurrence of part failure, UAI disposition, does not affect end customer Major SCAR issuance -20, Minor -10 from Quality/Delivery rating Late/Rejected SCAR is an additional -10 to Quality/Delivery rating Power & Propulsion Systems We Power Freedom L-3 Proprietary 31 Supplier Corrective Action Request (SCAR) Combat Propulsion Systems Additional tools for SCAR guidance are available on the Quality website. http://www2.l-3com.com/cps/quality.html SCAR guidance template Process Flow Control Plan Your SQA commodity lead is trained to coach on SCAR requirements and expectations. Please do not hesitate to contact your SQA commodity lead for support. Power & Propulsion Systems We Power Freedom L-3 Proprietary 32 SCAR submission expectations Combat Propulsion Systems Effective root cause analysis required for approval – Tools provided (5 Why’s and Fishbone diagram) – Will not accept ‘training’ or ‘operator error’ as root cause-keep going! Robust corrective and preventive action – An action is not preventable if a human is involved. Eliminate poor processes, decision points and automate where possible – Behavior is not preventable Cannot control a culture or a behavior Power & Propulsion Systems We Power Freedom L-3 Proprietary 33 Supplier Quality Material Report (SQMR) Combat Propulsion Systems Supplier Quality Material Reports (SQMR's) are a deviation request resulting from when the parts produced do not meet contract. SQMR’s are intended to address minor non-conformances discovered on L-3 CPS product located in the supplier's facility. Request does not imply consent. Suppliers cannot conduct Material Review Board (MRB) activities or dispositions on L-3 CPS material unless specifically given authority in writing. Suppliers may be allowed the use of a SQMR for a maximum of one (1) lot of material during the life of a purchase order for a specific minor non-conformance. Suppliers shall complete the SQMR and submit to your SQA commodity lead and commodity buyer agent. Upon completion of the L-3 CPS MRB action and processing, the supplier will be notified of the result of that review. If the final disposition is "use-as-is" or "repair", the supplier must document the SQMR number on the packing slip and on the shipping container. SQMR’s dispositioned as supplier caused result in a -15 point penalty to your Quality rating. Final disposition of SQMR will be forwarded to the supplier for record retention purposes and be required to follow the indicated disposition. The SQMR form can be found on the L-3 CPS Supplier Quality website: http://www2.l-3com.com/cps/quality.html • SQMR (Supplier Quality Material Report) Power & Propulsion Systems We Power Freedom L-3 Proprietary 34 Supplier Process Change Request (SPCR) Combat Propulsion Systems The Supplier Process Change Request (SPCR) is the form required for requesting the approval of a process change. Process changes with must have written approval of the commodity buyer agent and SQA commodity lead. Request does not imply consent. Contact your SQA commodity lead and commodity buyer agent prior to making any changes to ensure requirements are met and delivery is not impacted. A request for written approval can be requested utilizing the Supplier Process Change Request form (SPCR). Requests for change that require Qualification Testing - a documented time line must be included with request. Email the completed form to your SQA commodity lead and commodity buyer agent. The SPCR form is available on the L-3 CPS Quality website: http://www2.l-3com.com/cps/quality.html • SPCR (Supplier Process Change Request) The SPCR will be returned to the supplier stating the disposition and required action. In the event an FAI/FPI is required, the SPCR number must be referenced on the Inspection Request form submitted to L-3 CPS. A copy of the SPCR must accompany the FAI/FPI data submittal package. Supplier must document the SPCR number on the packing slip and on the shipping container. Power & Propulsion Systems We Power Freedom L-3 Proprietary 35 First Piece Inspection Combat Propulsion Systems If QY11 appears on your P.O, FPI is imposed. Read the clause in its entirety for complete requirements. L-3 CPS requires a First Piece Inspection (FPI) under the following circumstances: 1. New part number to supplier 2. Process/configuration change by supplier 3. 12 month interruption in production 4. Drawing revision change 5. Corrective Action An FPI is considered extended by L-3 CPS from one purchase order to the next providing the above criteria does not apply. Supplier shall download the Inspection Request form available on the L-3 CPS Quality website: http://www2.l-3com.com/cps/quality.html Inspection Request Form Power & Propulsion Systems We Power Freedom L-3 Proprietary 36 First Piece Inspection Combat Propulsion Systems A complete list of documents required for successful package submission is included in the AS9102 forms. As part of the Supplier Rating System performance metrics, suppliers are measured on First Pass Yield (FPY) for FAI, FPI and Source Inspection (SI) submissions. If your SQA commodity lead detects a negative, systemic trend in FPY performance metrics, SQA can issue a SCAR. A desktop FAI approval may be allowed at the discretion of an L-3 CPS SQA representative in lieu of an onsite. If a desktop FAI is permitted, a copy of the shipper will be requested by the L-3 CPS SQA representative for stamped approval, which authorizes shipment to L-3 CPS. FAI must be approved prior to shipment on any order. An L-3 CPS representative will send a copy of the work directive with the stamped packing list/shipper for your records. Please contact your SQA commodity lead or commodity buyer agent with any questions you may have regarding FAI or FPI requirements to your purchase order. Power & Propulsion Systems We Power Freedom L-3 Proprietary 37 First Article Inspection Combat Propulsion Systems If QX2 is flowed on your P.O, FAI is imposed. Please read QX2 Section 3.0 in its entirety for FAI requirements. A First Article Inspection (FAI) to the most current revision of AS9102 shall be performed when any of the following events apply: 1. A new part number to the supplier 2. A natural or man-made event, which may adversely affect the manufacturing process. 3. A lapse in delivery for two years or greater. 4. A change in the manufacturing source(s), process(es), inspection method(s), location of manufacture, tooling or materials, that can potentially affect fit, form or function. 1. 2. 3. Fit: the ability of an item to physically interface or interconnect with or become an integral part of another item. Form: shape, size, dimension, mass, weight and other parameters which uniquely characterize an item. Function: the action or actions that an item is designed to perform. 5. A change in the design affecting fit, form or function of the part. 6. A change in the numerical control program or translation to another media that can potentially affect fit, form, or function. 7. As the result of a Corrective Action, as applicable Power & Propulsion Systems We Power Freedom L-3 Proprietary 38 First Article Inspection Combat Propulsion Systems Supplier shall download the Inspection Request form and AS9102 forms available on the L-3 CPS Quality website: http://www2.l-3com.com/cps/quality.html Inspection Request Form AS9102 forms A complete list of documents required for successful package submission is included in the AS9102 forms. As part of the Supplier Rating System performance metrics, suppliers are measured on First Pass Yield (FPY) for FAI, FPI and Source Inspection (SI) submissions. If your SQA commodity lead detects a negative, systemic trend in FPY performance metrics, SQA can issue a SCAR. For training support, a link to the International Aerospace Quality Group (IAQG) First Article Inspection deployment resource and FAI training materials are available. AS9102 Deployment resource IAQG FAI Training Instructions Please contact your SQA commodity lead or commodity buyer agent with any questions you may have regarding FAI or FPI requirements to your purchase order. Power & Propulsion Systems We Power Freedom L-3 Proprietary 39 First Article Inspection Combat Propulsion Systems If an on-site verification of FAI is required due to performance issues, you will be notified by your SQA commodity lead. A documentation review must be conducted prior to the onsite inspection. A completed data package shall meet the requirements of the data package submittal requirements attached to the Inspection Request form. Suppliers shall be responsible for all costs associated with L-3 CPS arranging to have source inspections performed at the suppliers facility. If an on-site verification is required, a five (5) day window shall be required for scheduling verification. A desktop FAI approval may be allowed at the discretion of an L-3 CPS SQA representative in lieu of an onsite. If a desktop FAI is permitted, a copy of the shipper will be requested by the L-3 CPS SQA representative for stamped approval, which authorizes shipment to L-3 CPS. FAI must be approved prior to shipment on any order. An L-3 CPS representative will send a copy of the work directive with the stamped packing list/shipper for your records. Power & Propulsion Systems We Power Freedom L-3 Proprietary 40 Graded Fastener Requirements Combat Propulsion Systems The QX7 Material Requirements quality clause applies to suppliers providing fasteners. Grade 5/Grade 8 hex head and socket head fasteners, with equivalent Grade 5 and Grade 8 chemistry, shall be purchased directly from only those manufacturers/distributors identified in the V701, the L-3 CPS Special Process approved suppliers-fasteners listing, and must be traceable to a known North American manufacturing source by the fastener head logo marking and written documentation. To obtain the latest copy of the current listing, please contact the commodity buyer agent for Fasteners. Power & Propulsion Systems We Power Freedom L-3 Proprietary 41 End Item Data Package (EIDP) Combat Propulsion Systems If a supplier is not a delegate stamp supplier, End Item Data Package (EIDP) submittals are required by the supplier for approval prior to product shipment. EIDP package requirements can be found in QX2, Section 8.0. Supplier shall download the Inspection Request form available on the L-3 CPS Quality website: http://www2.l-3com.com/cps/quality.html Inspection Request Form The supplier shall email the completed data package to the DLCPS-SQA@L3com.com for approval. A copy of the shipper will be requested by the L-3 CPS representative for stamped approval, authorizing shipment. An L-3 CPS representative will send a copy of the work directive with the stamped packing list/shipper for your records. Power & Propulsion Systems We Power Freedom L-3 Proprietary 42 Inspection & Sampling Plan Combat Propulsion Systems L-3 CPS utilizes the ANSI/ASQ Z1.4 standard Acceptable Quality Level (AQL) 4.0 sample plan for determining acceptable quality levels. Suppliers shall inspect finished product per the AQL 4.0 sampling plan for normal inspection where sampling plans are applied, unless specified by other contract document. This sampling plan shall be flowed to your sub tiers. Accept on zero defects and reject the lot on one or more defects. Order of precedence: – P.O – Drawing – Performance specification – QAP, SQAP, or QAR – Standard of AQL 4.0 Power & Propulsion Systems We Power Freedom L-3 Proprietary 43 Inspection & Sampling Plan Combat Propulsion Systems Power & Propulsion Systems We Power Freedom L-3 Proprietary 44 L-3 CPS Acronyms and Abbreviations Combat Propulsion Systems Power & Propulsion Systems We Power Freedom L-3 Proprietary 45