ES305: Virtual Tools in Engineering Design

advertisement

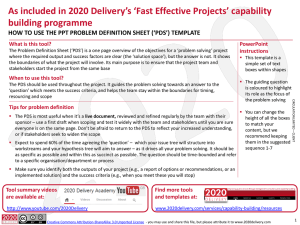

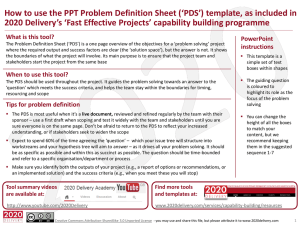

ES305: Virtual Tools in Engineering Design: The Eng. Design Process James Carroll, Associate Professor Electrical and Computer Engineering Total Design • Total Design is a systematic process – from Identification of market/user need – to selling of a product that meets the need • The process is also referred to as the Product Delivery Process or Product Development Process (PDP) • The process is centered on the Design Core – a set of activities central to all PDP The Design Core • Consists of: – a market (user need) – the starting point – product design specification (PDS) – conceptual design – detailed design – manufacturing – sales – the ending point The Design Core • An iterative process with information flowing in all directions • Inputs include techniques for – analysis, synthesis, decision making, modeling, etc. – some are discipline or technology dependent, e.g., strength of materials, some are not The Design Core • Current trends in current design practices – Life-cycle design: concept to final disposal – Design for manufacture and assembly – Design for quality – Faster design cycles (concurrent engineering) – Engineering without walls, e.g., virtual corporations – Design for export using global standards, e.g., the EU RoHS Directive (calls for "the restriction of the use of certain hazardous substances in electrical and electronic equipment“) Product Design Specification • A statement of need that overviews the product to be designed – often called a brief – places boundaries on the subsequent design activities which are carried out within the envelope of the PDS Product Design Specification • Elements of a PDS often address – desired performance & service life; operating environment & maintenance; target cost; competition; size, weight & shipping; manufacturing & quantity; materials; aesthetics, appearance & finish; ergonomics; quality and reliability; shelf life & storage; testing & safety; market, legal, social and political constraints; installation; documentation; disposal, etc. Product Design Specification Conceptual Design (Synthesis) • Involves the generation of solutions to meet the stated needs of the PDS (or partial PDS) and the evaluation of these solutions to select the optimum candidate • Can be applied at the complete system, subsystem or component level of the design process • Three primary components, referred to as controlled convergence – Concept generation (individuals) – Development of evaluation criteria (groups) – Evaluation/selection of concepts (groups) Conceptual Design (Synthesis) • Common techniques used to generate ideas in the context of controlled convergence – analogy – brainstorming/sketch-storming – attribute listing – checklists – inversion – combination Conceptual Design (Synthesis) • Most techniques used to evaluate concepts involve: 1. 2. 3. 4. 5. • Selecting criteria Assigning weighting factors Developing a rating scale Constructing a decision making structure Determining the best design alternative Common evaluation techniques include weighted objectives trees and evaluation matrices, morphological charts, and black boxes Conceptual Design (Synthesis) • The outcome of this phase of the design process should be – a complete concept engineered to an acceptable level to establish its validity – e.g., set of part layouts or schematic drawings using CAD/CAE tools: a focus of this course! – e.g., hand or CAE-based calculations that estimate the system performance, etc. Detailed (Technical) Design • In this stage of the process, the individual subsystems and components are designed in detail – this level of design relies heavily on the technical/engineering disciplines • It is often helpful to come up with individual component design specifications (CDS) – similar to a PDS w.r.t. elements addressed – includes issues such as component interfacing and a component’s effect of the whole part, etc. Detailed (Technical) Design • General pointers – never carry out detailed design without reference to a specific concept or vice versa – interactions between different subsystems must be considered within the overall constraints of those subsystems – keep in mind that the very act of defining a component places constraints on the overall system – keep in mind load lines, cost, size, simplicity, standardization of parts, ways of manufacturing, etc. Manufacturing • • The design of a product together with its manufacturing process is called concurrent engineering The aims of design for manufacture (DFM) – minimize component and assembly cost – minimize development cycle time – produce higher-quality products • Ideally the detailed design of the product is performed simultaneously with the manufacturing process Sales (Marketing) • Two primary aspects – Establishing the nature and characteristics of the product to be made by means of market research – Marketing the final product, e.g., distribution, service, etc. • Example questions for potential customers – desired product performance? – desired product cost? – time-scale: when do you want a product with this performance? Will less faster be better? Related Topics • • • • • • Design management, e.g., design reviews The computer/internet as a tool to drive total design, e.g., CAD/CAE and visualization tools, web-based tools, etc. Quality Function Deployment (QFD) – developed to better assess customer needs and drive the total design process Functional cost analysis Failure mode and effect analysis Fault tree analysis References • S. Pugh, “Total Design,” Addison Wesley, 1991