Beef and Veal

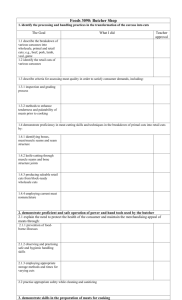

advertisement

Beef and Veal Fabrication and ID Sessions 6 and 7 1 Protein Fabrication Agenda Ingredient and Materials Knowledge Goal Quiz Review Beef and Veal 1. 2. 3. 4. 5. Definitions Breeds and Primals: Using the NAMP Standards Standards of Quality Handling and Storage Fabrication a. b. c. Cutting Steaks Following Seams Using the Grinder 2 Protein Fabrication Quiz Review www.quia.com 3 Protein Fabrication Meat-Definition The flesh of furred land animals 4 Protein Fabrication Meat-Definition Beef Meat from cattle (usually steers) raised for such purpose (slaughtered between Veal Meat from young male cattle born to female dairy cows 5 Protein Fabrication Breeds Scottish Highland – for Grazing Black Angus Wagyu Hereford 6 Protein Fabrication Meat is composed of 72 % water 20 % protein 7 % fat 1 % minerals. 7 Protein Fabrication Muscle composition Why some cuts tender and some are tough. 8 Protein Fabrication How can you tell a tender cut from a tough one before cooking? Location on carcass dictates tough or tenderness from actual muscle usage. Length of fibers short= tender long and stringy=tough Amount of intramuscular fat or marbling. 9 Protein Fabrication Muscle fiber vs. connective tissue 10 Protein Fabrication Collagen vs. Elastin Collagen ElastinCollagen Elastin Protein based, white, dissolvable substance that is connective tissue between muscles. It breaks down in the presents of low heat and moisture. Tenderized by acids. In slow cooking, collagen is broken down into gelatin and water. Protein based, yellow colored, connective tissue that is not broken down by heat or moisture. Only removal in meat or mechanical breaking up of the fibers in processed meat products can tenderize a product. 11 Protein Fabrication Inspection & Grading Inspection Grading Inspection Guarantee of wholesomeness, not quality or tenderness. Animal not diseased and meat is clean. Indicated by round inspection stamp USDA Required by federal law- all meat must be inspected. Grading Grading is a quality designation Indicated by a shield stamp It is not required by law. Reliability of private grades depends only upon the reputation of the packer. 12 Protein Fabrication Aging meats A means by which meat fibers break down and get tender. The enzymes of decomposition continue to function after death. If meat is held in a clean and cold environment, this break down function renders the meat more palatable, and tender. Aging meat is a procedure that requires, a clean environment, free from dangerous bacteria, not just cold, but the correct humidity. 13 Protein Fabrication Aging meats Wet aging – Primal cuts that are wrapped in a Cryovac plastic wrap. Air tight and moisture proof, cuts are held in vacuumed packed plastic and age. Bacteria and contaminants are sealed out, and moisture is sealed in, so the meat doesn’t loose water weight. Unfortunately for the consumer, when cooking wet aged meat, there is much moisture loss during this process. 14 Protein Fabrication Aging meats Dry aging – Dry aging is the process of storing meats, usually large cuts, under carefully controlled conditions. The meat is not packaged or wrapped and is exposed to air on all sides. Temperature, humidity, and air circulation are precisely controlled to prevent spoilage. Ultraviolet lights are sometimes used in aging coolers to kill bacteria. 15 Protein Fabrication Irradiation Exposing meat to radiation to kill harmful bacteria such as e-coli. Upside: meat can be kept longer, and bacteria is destroyed. Downside: Meat has molecular damage and unknown long term effects due to the radiation/ consumption. Also, radiation by-products need to be safely stored and disposed of…major issue. 16 Protein Fabrication Butchering and dressing Slaughtering, processing and fabrication of large animals for human consumption. After the animal is killed and bled and the hide removed, the animal is inspected for sores, tumors, bruises and other flaws. If the meat is deemed safe and sanitary, it is then broken down into carcasses, partial carcasses, primal cuts and fabricated cuts. 17 Protein Fabrication Butchering and dressing Carcasses: Whole animal, minus the entrails, head, hooves and hide. Rarely seen anymore in food service. Replaced by boxed beef or primal cuts. Lack of trained meat cutters and labor costs. Sides, quarters, foresaddles, and hindquarters or saddles Again, these larger cuts are no longer frequently used in food service. Beef is cut into halves through the back bone. Sides are divided between the 12 and 13th ribs into forequarter and hindquarter sections. 18 Protein Fabrication Primal cuts Wholesale cuts that are the industry standards. These are the primary divisions of the larger cuts. They are smaller and more manageable in many food service kitchens. Are still large enough to allow a variety of different cuts for different uses or needs. And are easier to utilize completely than quarters or halves. 19 Protein Fabrication There are 8 primal cuts according to the National Livestock and Meat Board Eight Primal Cuts of Beef: chuck rib short loin sirloin round brisket/shank short plate flank 20 Protein Fabrication Veal there are 7 primal cuts according to the National Livestock and Meat Board Seven Primal Cuts of Veal: shoulder rib loin sirloin leg breast/shank flank 21 Protein Fabrication After Primal Cuts Sub primal cuts Subprimal cuts are cut from a primal down to a more manageable size. Fabricated cuts Even smaller cuts for foodservice, such as roasts, steaks, chops, cutlets, stewing meats, ground meat and so forth as set forth by the IMPS/NAMPS specifications. 22 Protein Fabrication Purchasing meats Getting value Specifications Size Weight Quality grade Yield grade portion size or NAMPS 23 Protein Fabrication Purchasing meats Deliveries: Check specifications Check weight Check condition Check state Store properly Wrapped to prevent burn Vapor proof wrapping to prevent freezer burn. Label and date. Keep less than 6 months if fatty cut/type – fat oxidation 24 Protein Fabrication Flavoring and Tenderization Techniques Larding Barding Pounding Marinating Jaccarding 25 Protein Fabrication