Dowel Joint

advertisement

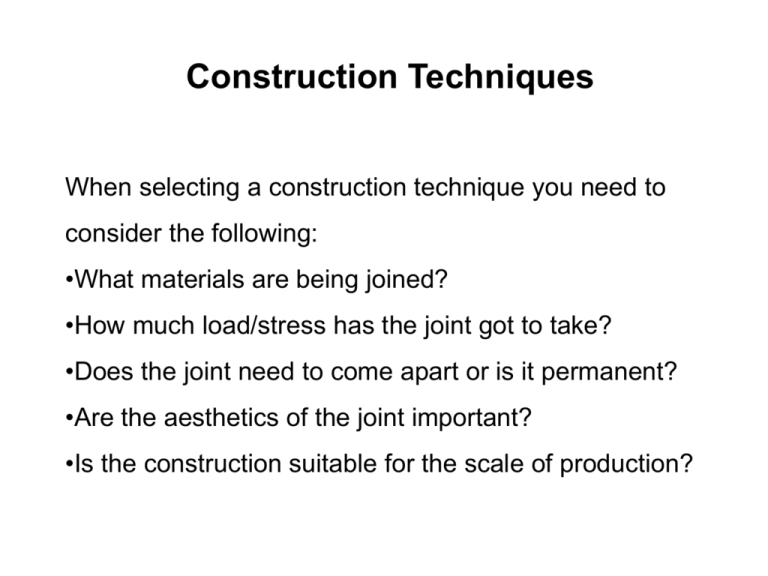

Construction Techniques When selecting a construction technique you need to consider the following: •What materials are being joined? •How much load/stress has the joint got to take? •Does the joint need to come apart or is it permanent? •Are the aesthetics of the joint important? •Is the construction suitable for the scale of production? The construction techniques have been split as below: Wood Metal Plastics Frame Joints Carcase Joints Biscuit & Router Joints KD Fittings Screw & Nails Soldering – Soft & Hard Brazing Welding – Gas & Electric Rivets Screw Threads Welding Frame Joints Frame joints tend to be made up of long thin pieces of wood forming rails and legs. They cover a wide variety of applications. Typical uses include: - Door Frames - Chairs - Table Frames - Picture/Mirror Frames - Window Frames - Bed Frames Mitre Joint This joint looks good but it is not interlocking so lacks strength. It can be used to produce any shape frame. Cross Halving Joint This joint can be used to produce corners, ‘T’ shapes or ‘+’ shapes. In a corner joint it is not interlocking so relies on the glue for strength. The most common use is in the ‘+’ form. There are better joints for corners or ‘T’ sections. This joint is ideal for smaller section The fretwork on the cabinet door shown left is jointed using cross halving joints Bridle Joint an interlocking joint. used when a light frame is needed and strength is not the main requirement. For example, a picture frame. Mortice & Tenon Joints This is the most common frame joint in use. It has the same gluing area as the bridle joint but it is contained within the frame. Carcase Joints These are the ‘box’ constructions. The pieces of wood tend to be boards rather than rails and legs. Typical applications for these types of joints include the following - Boxes of all varieties - Chests - Book Cases - Cabinets eg. Bedside or Display - Drawers Mitre Joint Veneer Keys Dowels This joint is difficult to cut accurately. If it is too big for the mitre saw it has to be planned by hand. It is not interlocking so relies on the glue to hold it. The joint can be strengthened by adding veneer keys or dowels as seen above Lap Butt Joint A fairly easy joint to cut but it lacks strength. It is not interlocking so relies on the glue. Dowel Joint A Dowel joint is created by drilling matching holes in both boards then inserting dowels to provide some strength. The dowels have chamfered ends and grooves cut along the sides. This is to allow air and glue to escape from the hole. Fluted Dowels To achieve accuracy a JIG is often used. This can be made from metal and acts as a guide for the drill bit Both Sides of Corner Comb or Finger Joint interlocking and very strong when glued but it does not have the wedging action of the Dovetail joint. It is quite difficult to cut by hand. Dovetail Joint very strong and attractive joint. It has a large gluing area and is interlocking. The wedge shape of the Dovetail prevents the joint being pulled apart even without glue. Housing Joint This joint is used to form ‘T’ joints. It is interlocking and strong when glued. It can be hidden by doing a stopped housing joint Biscuit Joint machine cut joint. can be used on corners on in the middle of boards to form ‘T’ joints. The biscuit cutter is a small saw blade that cuts a groove in both sides of the joint. A biscuit is then glued in between the two. The glue makes the biscuit swell giving a very tight joint. The biscuits are laid out to mark where to cut Both sides of the joint have matching slots The machine cuts the slots The biscuits are glued in place The Electric Router The electric router can be used to cut very accurate parallel housing joints. This is ideal for jointing manufactured boards because the cutters are available in the same thicknesses as manufactured boards ie. 3,6,9,12,15,18mm The Router can have different cutters inserted to give different effects. These include cutting dovetails and mouldings as shown below KD Fittings KD (Knock Down) Fittings are used in the industrial production of furniture. ideal for joining manufactured boards together. knock down (take apart). flat pack in boxes and assembled at home by the customer. CNC machines are set up to drill all the holes in the appropriate places ready for the fittings to push in. The Modesty Block or Corner Block is the most basic KD Fitting. Cam Fitting Both parts fit into pre-drilled holes When pushed together they are locked in place by rotating the cam with a screwdriver. Scan Fitting fittings will not decrease in strength if they are taken apart several times because they are not gripping into the chipboard. A major problem with KD fitting constructions is that they lack rigidity. An uneven floor can distort the shape of the cabinet. This makes it difficult to use conventional hinges because they have no adjustment. Special hinges had to be designed Hinges The hinge shown above allows adjustment in 3 directions Screws & Nails When using screws you need to know the core and thread diameters as shown above The clearance hole is the Thread Diameter and the pilot hole is the Core Diameter Coach Screw Coach screws are used for large applications. They are driven in using a spanner because the force required would be beyond a screwdriver. From the left these are Round Wire, Oval or lost head, Panel Pins, Clout nail and a Staple To increase the holding power of nails they can be dovetailed This helps to prevent them being pulled out. Which Process? Brazing Welding Yes No No Yes Yes No No Aluminium No No Yes but difficult Yes but difficult Steel Yes Yes Yes Yes Stainless Steel No No Yes Yes but difficult Soft Solder Hard Solder Copper Yes Brass Rivets produce fixed permanent joints or act as pivoting points allowing two pieces to move over each other as in scissors or shears. Rivets must be made from a malleable metal as they need to be shaped. There are 4 common rivet forms that can be used which are shown below. An alternative to the traditional rivets is the Pop Rivet. This is applied using a gun and is ideal if easy access is only available from one side. Fittings Involving Screw Threads Thread details you need to know Types of Fittings BOLT Machine SCREW Set Grub Screw The pictures above show the 3 main fittings. A variety of different heads are available that are driven in with a screwdriver, spanner or allen key. The most common nuts are hexagon nut or the wing nut that can be done with fingers. There are times when it is very important for the nut not to come off eg. On a car wheel. There are 2 methods shown above, The lock nut, the castle nut and split pin and the nyloc nut. washers spread the load and prevent damage to the surface. Washers can also prevent the nut coming off through vibration. Shown below are a Plain Washer, a Spring Washer and a Serrated Washer Self tapping screws can join non-ferrous metals or plastics. They are made from hardened steel and will cut their own thread. A pilot hole must be drilled first to the core diameter Cutting Screw Threads - Taps and Dies The Tap produces female threads Tap Wrench The split die allows slight adjustment to the size of the male thread. The Die is held in a Die Stock shown below. The adjustment is made by adjusting the 3 screws Construction Techniques Questions Which joint would you use for a hexagonal picture frame? Why is the joint on the left better than the joint on the right? Which would be the best joint for the fret work cross below? Why is the mitre joint not very strong? Why is the dowel below not suitable for use in a dowel joint? How can you accurately drill 10 holes all matching for a dowel joint? Why is a mortise & tenon joint better than a bridle joint because they have the same gluing area? Why is a lap dovetail used instead of a through dovetail for a drawer front? 19-What is aesthetically unattractive with the housing joint below? The housing joint below would fall apart if pulled hard. Sketch how the joint could be improved? What does KD mean? Why is the modesty block a poor quality fitting? Why is the cam fitting more suited to repeated dismantling than the modesty block? Why do hinges on self assemble wardrobes need to have adjustment in 3 directions? How can you increase the holding power of nails? Why is a coach screw driven in with a spanner instead of a screwdriver? Soft solder is an alloy of what? Why is welding stronger than Brazing? Why is welding Aluminium difficult? Why does the metal in a rivet need to be malleable? What is the thread pitch? Where would you find a castle nut & split pin? What tool cuts a female thread? What is the main reason for using a washer? Why are self tapping screws made from hardened steel? When using brass screws in wood a steel one should be put in first. Why?