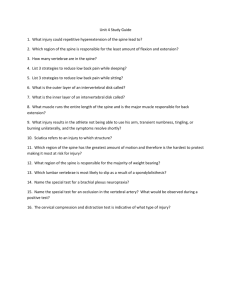

ME 495a SENIOR DESIGN PROPOSAL

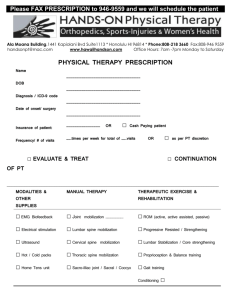

advertisement