Hydraulic Fracking: Multimedia Environmental Assessment

advertisement

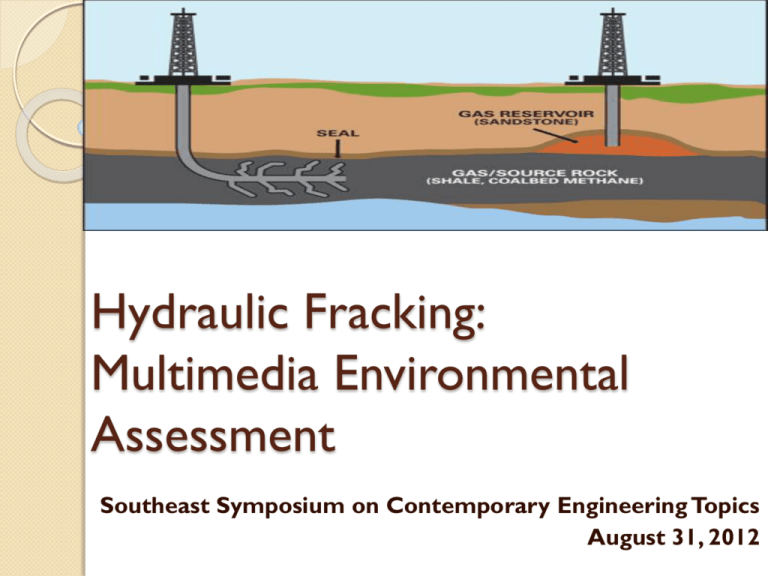

Hydraulic Fracking: Multimedia Environmental Assessment Southeast Symposium on Contemporary Engineering Topics August 31, 2012 Outline Emergence Hydraulic Fracturing Process Overview U.S. geographical distribution Environmental Risks U.S. Energy Supply Regulations Economics Emergence of Hydraulic Fracturing 1860s: Fracturing as a method to stimulate shallow, hard rock oil wells. Applied by oil producers in Pennsylvania, New York, Kentucky, and West Virginia by using liquid and later also solidified nitroglycerin. 1970s: United States government initiated the Eastern Gas Shales Project. 1977: Department of Energy pioneered massive hydraulic fracturing in tight sandstone formations. Between 2005 and 2010: Shale-gas industry in the United States grew by 45% a year. Between 2005 and 2012: Shale gas increased from 4% to 24%. What is hydraulic fracturing? Also called “fracking” A process of initiating, and subsequently propagating a fracture in a rock layer, by injecting the pressurized fluid The fracturing is done from a wellbore drilled into reservoir rock formations, in order to increase the extraction and ultimate recovery rates of oil and natural gas 4 What is shale? • • • • Fine-grained sedimentary rock composed of mud and tiny fragments of other minerals Deposited in very slow moving water, lakes and lagoonal deposits, in river deltas, on flood plains and offshore from beach sands. Characterized by breaks along thin laminae or parallel layering Usually has low permeability 5 Role of Hydraulic Fracturing in America’s Energy Supply 90% of oil and gas wells in the United States undergo fracturing to stimulate production. The use of hydraulic fracturing is estimated to account for 30% of U.S. recoverable oil and gas reserves, and is responsible for the addition of 7 billion barrels of oil and 600 trillion cubic feet of natural gas. Without hydraulic fracturing, we would be producing much less oil and gas in America, relying more on foreign imports to meet the energy demands of our nation. How does hydraulic fracturing work? Pump the fracturing fluid into the wellbore to increase the pressure downhole. Formation begins to crack; fracturing fluid enters the crack farther into the formation. A solid proppant keeps this fracture open after the injection stops. Injected fluid: water, gels, foams, and compressed gases, including nitrogen, carbon dioxide and air Proppant: sand, resin-coated sand, and man-made ceramics The propped hydraulic fracture then becomes a high permeability conduit through which the formation fluids can flow to the well. 8 Different shale gas deposits across the country US Shale Gas resources (tcf) 6% 0% North-East 10% 8% Gulf Coast 13% Mid-continent 63% South-west 0% US Shale oil resources (billion barrels) 12% 63% 0% 17% North-East 8% Gulf Coast Mid-continent South-west 1. 86% of the total 750 trillion cubic feet of recoverable shale gas are located in the Northeast, Gulf Coast, and Southwest regions. 2. In the three regions, the largest shale gas plays are the Marcellus (410.3 trillion cubic feet, 55 percent of the total), Haynesville (74.7 trillion cubic feet, 10 percent of the total), and Barnett (43.4 trillion cubic feet, 6 percent of the total). Shale Natural Gas Reserves Source: EIA, http://www.eia.doe.gov/oil_gas/natural_gas/data_publications/crude_oil_natural_gas_reserves/cr.html. 12 1. EIA projects 827 trillion cubic feet (Tcf) of recoverable natural gas from U.S. shales using currently available technology. 2. US current consumption: 23 Tcf per year, 20 Tcf is produces and rest is imported 3. Shale gas resources represent 36 years of current consumption. 4. One Tcf of natural gas = Heat 15 million homes for 1 year = 100 billion kilowatt-hours of electricity = 12 million natural-gas-fired vehicles for 1 year. Water Use Statistics Source Volume (Gallons) Frac Groundwater 1,230,712,693 Frac Surface Water Drilling Rig Groundwater Supply Drilling Rig Surface Water Supply 8,223,152,516 Other Groundwater Other Surface Water, Other Surface Water <0.5% 879,649,632 Rig Supply Ground Water 8% Frac Supply Ground Water 12% 157,839,504 155,545,829 39,007,638 Other Ground Water 1% Rig Supply Surface Water 2% Source Volume (Gallons) Frac Groundwater 1,230,712,693 Frac Surface Water Drilling Rig Groundwater Supply Drilling Rig Surface Water Supply 8,223,152,516 Other Groundwater Other Surface Water, 879,649,632 157,839,504 155,545,829 39,007,638 Frac Supply Surface Water 77% Average Water Demands of Well Fracking Barnett ◦ Water Use (gallons/well): 2,300,000 Haynesville ◦ Water Use: 2,700,000 Marcellus (PA) ◦ Water Use: 3,800,000 Source: EPA Frac Study Plan 15 Environmental Concerns • Chemical concerns o o Pumping chemicals near water table Failure in pits and liners could leak chemicals • High water usage • Air Emissions from truck use • Surface Area used Risk to Groundwater Little to no evidence of direct impact to groundwater. Potential contamination of groundwater if mechanical integrity of well is compromised. Lowering aquifer water levels by water consumption from fracking may: ◦ Affect water quality by exposing mineral to oxygenrich environment; ◦ Increasing salination and potential chemical contamination; ◦ Increase bacterial growth; ◦ Cause upwelling of lower quality water from deeper within aquifers. Sources: http://www.api.org/policy/exploration/hydraulicfracturing/ and EPA Frac Study Plan 17 Risks to Surface Water: Flowback After fracing, pressure decreases and frac fluid flows back to the surface. Amount of frac fluid recovered as flowback varies from 25% to 75%. Flowback rate in first few days can exceed 100,000 gallons per day ◦ Will drop to ~ 50 gallons per day over time As of 2009, none of 27 states with fracing require reporting of flowback Flowback can have frac fluids and high TDS values, concentrations of major ions (e.g. barium, bromide, calcium, iron), radionuclides, VOC, and other natural occurring elements. Depleted surface water sources may affect flow, depth, temperature and reduce dilution of surface water sources increase contaminations concentrations. Source: EPA Frac Study Plan 18 Handling/Disposing of Flowback Flowback and produced water are held in storage tanks and water impoundment pits prior to and during treatment, recycling, and disposal. Impoundments may be temporary or long-term. Underground injection is primary method for disposal for flowback and produced water. ◦ Concerns regarding injection capacity and cost of trucking wastewater to injection site. Potential for use of publicly owned treatment works (POTW) or commercial treatment facilities if in populated areas. ◦ POTWs not designed to treat fracing wastewaters Releases, leaks, and/or spills involving storage and transportation of flowback and produced water could contaminate shallow drinking water aquifers and surface water bodies. Source: EPA Frac Study Plan 19 Federal Regulations 2003 Memorandum Agreement ◦ 3 Largest oil service companies agreed to eliminate diesel fuel from fracturing coal bed methane seams 2004 EPA Study ◦ Injection of fracturing fluids into coal bed methane wells posed little or no threat to underground sources of drinking water ◦ Identified diesel fuel as a constituent of concern Federal Regulations contd. Fracking, except for fracking with diesel fuel, was excluded from Safe Drinking Water Act definition of “underground injection” by the Energy Policy Act of 2005. (42 U.S.C. 300h(d)(1)(B)(ii)). ◦ Bills introduced March 15, 2011 to remove exemption (HR 1084). ◦ Similar bills introduced in Senate (S 587) and in past (2009 – HR 2766). Definition of “underground injection” ◦ (1)(A) - means the subsurface emplacement of fluids by well injection; and ◦ (1)(B) excludes – (i) the underground injection of natural gas for purposes of storage; and (ii) the underground injection of fluids or propping agents (other than diesel fuels) pursuant to hydraulic fracturing operations related to oil, gas, or geothermal production activities. 21 Clean Water Act and State Regulation CWA covers the discharge of water produced by hydrofracturing regulations Regulated by the National Pollutant Discharge Elimination System UIC Program Requirements To be issued a permit, the applicant must show that the underground injection will not endanger drinking water resources. UIC program must require inspection, monitoring, recordkeeping, and reporting requirements on those who employ underground injection. The EPA can administer a UIC Program itself, or delegate that authority to the states. The FRAC Act Introduced on June 9, 2009 Aims to define hydraulic fracturing as a federally regulated activity under the Safe Drinking Water Act. Energy industry to disclose the chemicals it mixes with the water and sand it pumps underground in the hydraulic fracturing process. Broaden the definition of “underground injection” to include hydraulic fracturing. EPA Hydraulic Fracking Study February 8, 2011 EPA releases Draft Hydraulic Fracturing Study Plan Study designed to examine “life cycle” of fracing, particularly potential affect to drinking water resources and human exposure to chemicals. Study will analyze and research questions involving: ◦ Water Acquisition; Chemical Mixing; Well Injection; Flowback and Produced Water; and Wastewater Treatment and Waste Disposal Study will include: ◦ Retrospective case studies, possibly in Barnett Shale counties of Wise and Denton Counties ◦ Prospective cases studies, possibly in Flower Mound/Bartonville. Study expected to be completed in 2012, with 2014 follow-up. In 2004, EPA conducted study finding that hydraulic fracturing in coal-bed methane wells pose little to no threat to underground drinking water. Sources: EPA Frac Study Plan and Evaluation of Impacts to Underground Sources of Drinking Water by Hydraulic Fracturing of Coalbed Methane Reservoirs (EPA 816-R-04-003), 2004. 25 Other Recent Studies and Reports April 16, 2011: ◦ Congressional report prepared by Waxman, Markey, and DeGette outlining chemicals used in fracing, including benzene, lead, and methanol. ◦ Alleged use of 29 chemicals that are known or possible carcinogens. April 2011: ◦ Prepublication of report by Cornell Professors that CO2 emissions from shale fracing are greater than coal. Sources: U.S. House Committee on Energy and Commerce, Chemical Used in Hydraulic Fracturing (April 2011) and Robert Howard, et al, Methane and the Greenhouse-Gas Footprint of Natural Gas from Shale Formations (2011). 26 US Economy and Hydraulic Fracking Study Results for the U.S. Economy Decrease in production of oil and natural gas, which results in increase in imports to meet the nation's energy demand. No Fracturing scenario: ◦ Oil and natural gas production losses, ◦ Increasing toll on U.S. economic performance from 2014 through 2020. ◦ 2014: GDP is lower by $374 billion and employment falls by 2.9 million jobs. ◦ Severe recession, exacerbating recovery and job growth. UIC Compliance scenario: ◦ Economic impacts also rise through 2014, ◦ GDP and employment both drop 0.5% ◦ 2014: GDP is $84 billion lower and there are 635,000 fewer jobs. Fluid Restrictions Scenario: ◦ GDP is lower by $172 billion and employment falls by 1.3 million jobs. COMPETING INTERESTS AND ISSUES Cheaper Fuel Jobs and Training Income for Landowners Greener than Oil and Coal Revenue for Local Communities and New York State Reduced Reliance on Imported Oil/National Security Implications Vs. Impacts on Water, Public Health and Safety Infrastructure Maintenance Costs Financial Impacts and Burdens Character of the Community Advocacy and Actions Quality of Life Opportunities for Consulting Firms Filing for permit application Effective ways to handle/dispose the flowback Regulation compliance Possible contamination with BTEX compounds Reporting and disclosing as per federal and state requirements