Document

advertisement

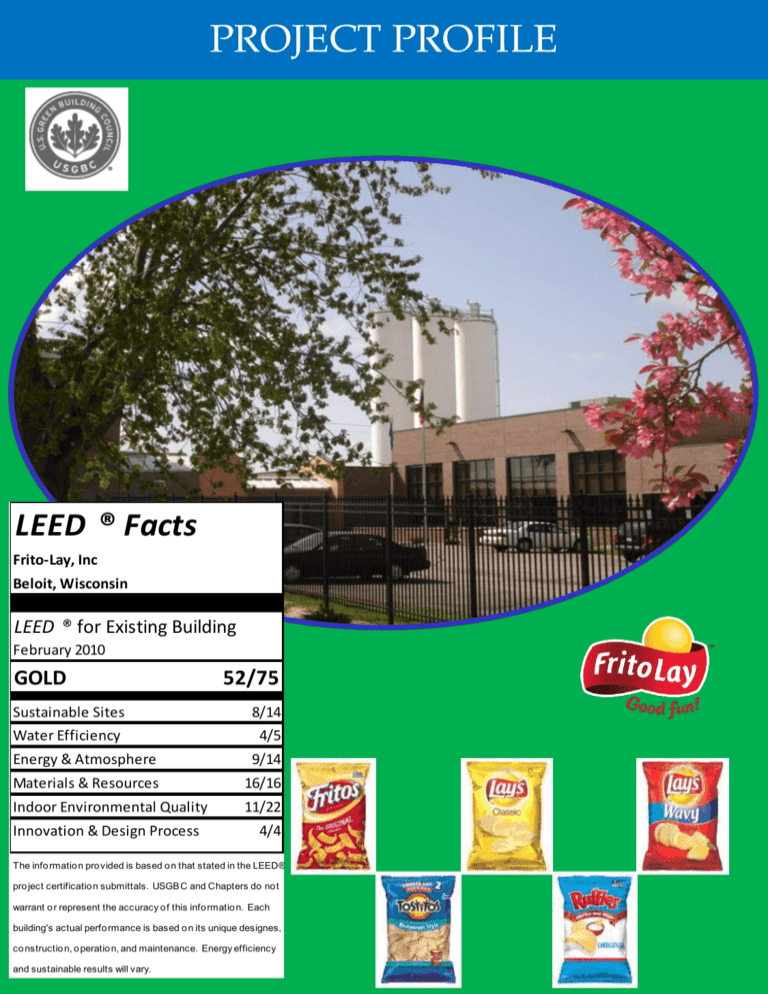

PROJECT PROFILE LEED ® Facts Frito-Lay, Inc Beloit, Wisconsin LEED ® for Existing Building February 2010 GOLD 52/75 Sustainable Sites 8/14 Water Efficiency 4/5 Energy & Atmosphere 9/14 Materials & Resources 16/16 Indoor Environmental Quality 11/22 Innovation & Design Process 4/4 The info rmatio n pro vided is based o n that stated in the LEED® pro ject certificatio n submittals. USGB C and Chapters do no t warrant o r represent the accuracy o f this info rmatio n. Each building's actual perfo rmance is based o n its unique designes, co nstructio n, o peratio n, and maintenance. Energy efficiency and sustainable results will vary. PROJECT PROFILE Frito-Lay, Inc. Beloit, Wisconsin SITE BACKGROUND The Beloit, Wisconsin facility opened in 1973 and has expanded over the years to 550,000 sq ft today, with 685 full time employees. The Site manufactures Lay’s, Ruffles, Wavy Lay’s, Doritos, Tostitos, Fritos, and Cheetos for a 7 state service area. STRATEGIES AND RESULTS Becoming LEED certified was the next logical step in the Beloit Site’s on-going journey in energy reduction and waste minimization. Since 1999, the Site has reduced its water usage by 50%, its natural gas usage by 40%, and its electrical usage by 20%. This has been accomplished primarily through employee engagement and capital projects. Projects include a heat recovery system to pre-heat fryer oil, recovering heat from the potato chip fryer to heat the building during winter months, and an absorption chiller to turn waste heat into cool air for summer months. Through these efforts the site has received the Award of Excellence in Resource Conservation in 2008 and 2011 (Frito-Lay North America award), the EPA Clean Air Award In 2012, and the Wisconsin Manufacturer of the Year Award in Sustainability in 2010. In 2007 the site started its zero landfill journey and has reduced its landfill waste by 75% between 2007 and 2012. The site has engaged owners in the recycling program and reuses over 99% of all multi-trip cardboard that is used in shipping the finished product. The site also conducts monthly waste meetings to focus on product waste and since 2010 it has reduced its finished waste by over 40%. The LEED certification process was completed in 2010. The certification process resulted in many people improvements including comfort surveys with action plans, reduced decibel cleaning equipment, bike rack additions, and car pool parking spots. The on-going process for Beloit is LEED for Life which is a comprehensive quarterly reporting process that ensures previous initiatives continue and the site continually improves in all areas sustainability.