specifications

advertisement

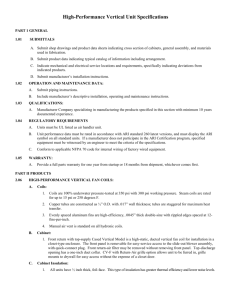

Vertical-Stack High-Rise Unit Specifications PART 1 GENERAL 1.01 SUBMITTALS A. Submit shop drawings and product data sheets indicating cross section of cabinets, general assembly, and materials used in fabrication. B. Submit product data indicating typical catalog of information including arrangement. C. Indicate mechanical and electrical service locations and requirements, specifically indicating deviations from indicated products. D. Submit manufacturer’s installation instructions. 1.02 1.03 OPERATION AND MAINTENANCE DATA: A. Submit piping instructions. B. Include manufacturer’s descriptive installation, operating and maintenance instructions. QUALIFICATIONS: A. 1.04 1.05 Manufacturer Company specializing in manufacturing the products specified in this section with minimum 10 years documented experience. REGULATORY REQUIREMENTS A. Units must be UL listed as air handler unit. B. Unit performance data must be rated in accordance with ARI standard 350 latest versions, and must display the ARI symbol on all standard units. If a manufacturer does not participate in the ARI Certification program, specified equipment must be witnessed by an engineer to meet the criteria of the specifications. C. Conform to applicable NFPA 70 code for internal wiring of factory wired equipment. WARRANTY: A. Provide a full parts warranty for one year from startup or 18 months from shipment, whichever comes first. PART II PRODUCTS 2.02 VERTICAL-STACK FAN COILS: A. B. Coils: 1. Coils are 100% underwater pressure-tested at 350 psi with 300 psi working pressure. Steam coils are rated for up to 15 psi or 250 degrees F. 2. Copper tubes are constructed as ½” O.D. with .017” wall thickness; tubes are staggered for maximum heat transfer. 3. Evenly spaced aluminum fins are high-efficiency, .0045” thick double-sine with rippled edges spaced at 12fins-per-inch. 4. Manual air vent is standard on all hydronic coils. Cabinet: 1. C. Basic unit construction is heavy 18-20 gauge galvanized steel, including framing, top panels, side panels and front panels with exposed corners and edges rounded. Perforated supply air knockouts located on all sides that can be factory or field removable. Cabinet Insulation: 1. All units have ½ inch thick, over three-pound density neoprene-coated fiberglass. This type of insulation has greater thermal efficiency and lower noise levels. D. E. F. G. Drain Pan: 1. Constructed of 18-gauge galvanized steel with welded seams, powder-coated epoxy with ¼” closed cell insulation. This helps eliminate rust or corrosion and assure sweat-proof operation under adverse dew-point conditions. 2. Drain pans are trapped for positive condensate drainage and has a formed p-trap drain connection. Blowers: 1. Double-width, double-inlet, forward curved blade and centrifugal wheels that are statically and dynamically balanced and generously sized for low-outlet velocities and quiet operation. Blower scrolls and wheels are galvanized for rust-free operation, and permanently lubricated ball bearings ensure long-service life. 2. Slide-out blowers with quick-connects for easy servicing. 3. Blower assembly wiring is provided enclosed in plastic tubing to further ensure whisper-quiet operation. Motors: 1. Provide wiring to junction box for single-point field connection. 2. Direct drive motors have quick-connect plug, permanent split capacitor, thermal overload protection, oversized bearings and oil reservoirs. 3. Custom motor mounts designed to reduce noise and eliminate vibration. 4. Stators are epoxy-dipped for better motor cooling and increased electrical protection. Controls: 1. Ball Valves -Full flow (full port) construction for maximum flow through the valve -UL (VQGU) rated. -600 PSI CWP (WOG) service pressure range (max pressure for the valve) -Valve is double seal tested under pressure before the valve leaves out plant . -Construction is hot forged brass with packing gland (PTFE) stem design. -Temperature range is -4F to +350 F. -Steam rated at 150 WSP (working steam pressure) 2. Control Valves The snap-on actuator is specifically designed for use with a two-way / three-way valve body. This combination provides convenient, reliable and easy installation for a variety of heating and cooling applications. The valve actuator is installed after the valve body has been installed onto the fan coil. The actuator has a variety of voltages and functions. The snap-on features the reliable synchronous motor driven spring return \operation proven out of millions of valves. The snap-on actuators are available in general close-off and high close-off, normally open and normally closed configurations, and a variety of motor voltages. The snap-on actuator mounts directly onto the body quickly and easily without the need for linkages and calibration. Operating pressure limits is 300 PSI. Control valves service hot and chilled water, and up to 50% Glycol. 3. Auto Flow Control For a pressure differential range of 2 to 80 PSI, the rubber diaphragm will flex into the contoured orifice plate to increase flow restriction as the pressure drop increases. Both the rubber diaphragm and the contoured orifice plate are rigidly controlled to provide a constant flow rate over the pressure differential range. This “flexing” of the rubber diaphragm against the fixed orifice plate makes the Auto Flow control difficult to clog and will not damage due to cavitations. The “flexing” action actually chews up debris to preventing clogging. Outside of the pressure drop window, the controller performs similar to a fixed orifice. 4. Thermostat 24-277 Volt, Manual, Heat/Cool, Heat/ Off/Cool, On/Off – Off Breaks Cool/ Heat/Fan – Gray H. I. Risers: 1. High-Rise units may be factory equipped with custom copper supply, return and condensate risers from ¾” to 3-1/2” to meet pressure drop requirements. Custom length risers available. Standard length is up to 10 feet. 2. Risers are bell-swaged three inches deep on the top, allowing for the next fan coil to be set in place with its risers entering the swaged ends. Risers are held by unique clamping method to allow piping expansion and contraction. Risers may be ordered with rear, right of left hand piping connections. Risers are built, tagged and shipped the way they will be installed. Thus, reducing handling and labor costs. Risers are secured for shipping by custom brackets at top and bottom of each fan coil. Electric Heat Electric heat may be furnished with either hydronic or DX coils and is factory mounted, wired, and tested option equipped with low-watt density (for long life) nichrome wire elements. The heater has a built-in, high limit, and fusible link to provide maximum safety. J. Filter: 1. K. Service Access: 1. L. One-inch thick fiberglass, throwaway, flatly mounted, with one clip on top that easily turns for easy maintenance without the use of tools. The coil, valve package, motor with blower wheel and housing can all be serviced through the front return air grille access door. Tagging & Crating: 1. Fan coils are custom tagged by room, floor, riser, etc; All units ship with corrugated covers over supply & return openings that keep units free of construction debris to enhance a successful start up. Units are protected by wooden-crates to insure damage-free units will arrive at your job site. Units with factory mounted risers have support brackets to protect from damage in handling and are crated the entire length. 2. All fan coils are 100% tested prior to shipment.