Oxyacet gas weld

advertisement

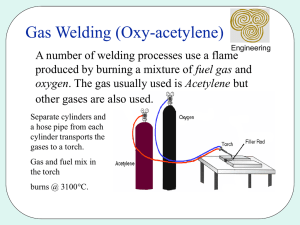

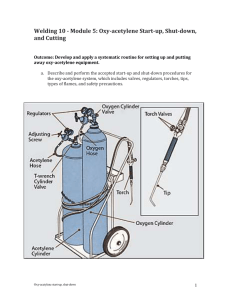

Oxyacetylene Welding Processes Oxyacetylene Welding (OAW) When gas welding derives the heat from the combustion of a fuel gas such as acetylene in combination with oxygen , then the process is called as oxy-acetylene gas welding The fuel gas generally used is acetylene because of the highest temp generated in the flame( up to 3500 0C ) The other useful fuel gases used for gas welding are Propylene ( C3H6 ) Propane ( C3H8 ) Hydrogen ( H2) Natural Gas ( CH4 + H2 ) Production of Acetylene (C2H2) •Virtually all the acetylene distributed for welding and cutting use is created by allowing calcium carbide (a man made product) to react with water. CaC2 +2H2O C2H2 + Ca( OH )2 Oxyacetylene Welding Figure : A typical oxyacetylene welding operation (OAW). Two stage chemical reaction of acetylene and oxygen: First stage reaction (inner cone of flame): Oxygen & acetylene in nearly equal proportion by volume burn in the inner white cone & forms carbon monoxide , while the hydrogen is liberated 2C2H2 + 2O2 4CO + 2H2 + heat Second stage reaction (outer envelope): The CO & H2 produced in the first stage further combine with atmospheric oxygen & give rise to outer bluish flame & results in CO2 and water vapours 4CO + 2H2 + 3O2 4CO2 + 2H2O + heat This CO2 acts as shielding gas to protect the weld from the surrounding atmosphere Combining above two equations : 2C2H2 + 5O2 4 CO2 + H2O From above equations it can be seen that 2 / 5 th of the oxygen necessary for complete combustion of acetylene is received from the oxygen cylinder and rest from the surrounding atmospheric air The oxyacetylene welding process uses a combination of oxygen and acetylene gas to provide a high temperature flame. OAW is a manual process in which the welder must personally control the the torch movement and filler rod application The term oxyfuel gas welding outfit refers to all the equipment needed to weld. Cylinders contain oxygen and acetylene gas at extremely high pressure. Typical Oxyacetylene Welding (OAW) Station Regulator Hoses • Hoses are are fabricated from • • • rubber Oxygen hoses are green in color and have right hand thread. Acetylene hoses are red in color with left hand thread. Left hand threads can be identified by a grove in the body of the nut and it may have “ACET” stamped on it Flame Settings • There are three distinct types of oxy-acetylene flames, • usually termed: – Neutral – Carburizing (or “excess acetylene”) – Oxidizing (or “excess oxygen” ) The type of flame produced depends upon the ratio of oxygen to acetylene in the gas mixture which leaves the torch tip. 9 Neutral and Oxidizing Flame Profiles 10 Oxyacetylene Flames Used in Welding Figure : Three basic types of oxyacetylene flames used in oxyfuel-gas welding and cutting operations: (a) neutral flame; (b) oxidizing flame; (c) carburizing, or reducing, flame. The gas mixture in (a) is basically equal volumes of oxygen and acetylene. 11 Flame definition • The neutral flame (Fig. 4-1) is produced when the ratio of oxygen to acetylene, in the mixture leaving the torch, is almost exactly one-to-one. It’s termed ”neutral” because it will usually have no chemical effect on the metal being welded. It will not oxidize the weld metal; it will not cause an increase in the carbon content of the weld metal. • The excess acetylene flame (Fig. 4-2), as its name implies, is created when the proportion of acetylene in the mixture is higher than that required to produce the neutral flame. Used on steel, it will cause an increase in the carbon content of the weld metal. • The oxidizing flame (Fig. 4-3) results from burning a mixture which contains more oxygen than required for a neutral flame. It will oxidize or ”burn” some of the metal being welded. 12 Torch Used in Oxyacetylene Welding Figure : (a) General view of and (b) cross-section of a torch used in oxyacetylene welding. The acetylene valve is opened first; the gas is lit with a spark lighter or a pilot light; then the oxygen valve is opened and the flame adjusted. (c) Basic equipment used in oxyfuel-gas welding. To ensure correct connections, all threads on acetylene fittings are lefthanded, whereas those for oxygen are right-handed. Oxygen regulators are usually painted green, acetylene regulators red. 13 GAS CUTTING… Manual Gas Cutting 14 GAS CUTTING • • • • • • • • Ferrous metal is heated in to red hot condition and a jet of pure oxygen is projected onto the surface, which rapidly oxidizes Oxides having lower melting point than the metal, melt and are blown away by the force of the jet, to make a cut Fast and efficient method of cutting steel to a high degree of accuracy Torch is different from welding Cutting torch has preheat orifice and one central orifice for oxygen jet PIERCING and GOUGING are two important operations Piercing, used to cut a hole at the centre of the plate or away from the edge of the plate Gouging, to cut a groove into the steel surface 15