PowerPoint

advertisement

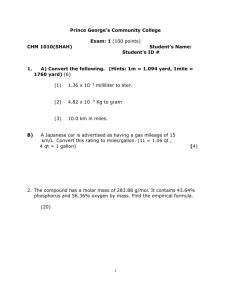

Application of phase diagrams in development of transparent polycrystalline oxides and thermal barrier coating Phase diagrams for production of transparent polycrystalline materials Phase diagrams for thermal barrier coating Phase chemistry in the development of transparent polycrystalline oxides Polycrystalline oxides are used for optical applications. The Al2O3 is a key element in high pressure sodium lamp. Number of oxides have been developed for optical applications. They are Al2O3, MgAl2O4, AlON, Y2O3. The aim is to obtain transparent polycrystalline single phase without porosity. 1. Y2O3 High melting point and capacity for wideband transmittance of Y2O3 presents interest for many infrared applications. Transparent Y2O3-Gd2O3 are unique X-ray scintillators. Pure un-doped Y2O3 can be fabricated to transparency by employing combination of fine active powders and high – temperature press forging and hot isostatic pressing. Success of these approaches relies not only on powder properties and application of pressure to enhance densification kinetics, but also on high purity to prevent precipitation of second phases or coloration from transitions or rare earth ions. Phase relations become critical when pressure-less method of sintering is selected to attain transparency. The options are liquid phase sintering, transient second phase sintering and doped solid state sintering. Non coloring aliovalent sintering aids for Y2O3 among rare earths is restricted to La and Gd, because these ions have no electronic transitions in the visible or infrared frequencies. Y2O3 with La2O3 additive Phase diagram was calculated using assessed thermodynamic data and reproduce available experimental data very well. Composition with 9 mol.% La2O3 was prepared by co-precipitation from the oxalates [1981Rhodes]. After calcination to get oxides, milling and isostatic pressing to get compacts, samples were heated up to 2150 °C in two phase C+H region with 25 vol.% H phase. Grain growth was retarded by the second phase formation. Pores were thought to remain attached to slow moving grain boundaries and annihilate by classic solid-state diffusion process. Temperature was lowered to 1900 °C inside single phase C solid solution field. Holding at this temperature dissolved H phase by slow diffusion process. Change was not displacive nor accompanied by volume change generating porosity. Instead pore free microstructure was achieved. Calculated phase diagram of the Y2O3-La2O3 system Single phase microstructure achieved by sintering at 2150 in twophase region and annealed at 1900°C in single phase region , (A) as polished and (B) as etched [1981Rhodes]. The Y2O3-Gd2O3 solid solutions for optical applications Scintillators are the materials which after being exited by ionizing radiation re-emit the absorbed energy in the form of light. Ceramic scintillators contain Y2O3-Gd2O3 solid solutions and one or more rare-earth activation oxides such as Eu2O3, Yb2O3 etc. The Gd2O3 is essential in absorbing X-rays while activators undergo electronic transitions that convert the energy to visible wavelengths for photodiode detection. According to the phase diagram of Y2O3-Gd2O3 system cubic(C)/monoclinic (B) phase boundary is ~1500°C at ~20 mol.% Y2O3. Ceramic processing temperatures such as powder synthesis (~1300°C) and sintering (1400°C) are lower and cubic phase is maintained. XRD shows that at 10 mol.% Y2O3 the B phase was produced. The measurements showed that light output was gradually increased with Y2O3 decrease down to 20 mol.% Y2O3 and then abruptly reduced because of lower scintillator conversion of B phase. The optimal composition is 20 mol.% Y2O3 and 3 mol.% Eu2O3. Phase diagram of Y2O3-Gd2O3 system [2007Zin] X-ray data and relative light output from [2004Kim] Al2O3 Translucent Al2O3 is a key element in high-pressure sodium lamps. High-pressure discharge experiments in sapphire tubing show considerable resistance to chemical attacks and improved color emission. Translucent Al2O3 envelope is used to prevent Na from attacking SiO2 in any glass. Al2O3-MgO Presence of MgO enhanced sintering by 1 to 2 %. Without MgO grain growth kinetic was unaffected prior discontinuous grain growth, which occurred at 99% density. MgO allowed normal grain growth up to achievement of theoretical density. Role of MgO is to decrease grain-boundary mobility and therefore poreboundary tendency for separation (pore entrapment within grains). MgO increases densification rate and grain-growth rate as well as surface diffusivity which keeps the pores on the boundary until they are annihilated by solid-state diffusion. MgO is microstructure stabilizer against green density variation, which might lead to porosity and other in-homogeneities. Sintered microstructure of Al2O3: Low porosity high-transmittance resulting from MgO sintering aid Al2O3-MgO Phase diagram shows very small solubility of MgO in Al2O3. Addition of TiOx and MgTiO3 increases solubility more than MgO alone. The ZrO2+MgO addition to Al2O3 also increases the solubility. Solid solution limit is an issue in development of translucent Al2O3 because MgAl2O4 precipitates act as light scattering centers due to their index of refraction difference with Al2O3. However pores are much greater scattering centers. Spinel MgAl2O4 precipitates in Al2O3 with 0.08 mass% MgO sintered at 1900°C in H2. According to phase diagram this composition should be within solubility range, but MgAl2O4 possibly precipitate during cooling. Using of the Y2O3 in combination with MgO as sintering aid for translucent Al2O3 allow to decrease sintering temperature and time, but the grain growth is more difficult to control. In case of sintering above eutectic temperature the porosity is reduced, but presence of liquid results in bimodal grain size distribution. Solubility limit (mass.% MgO) in corundum Spinel MgAl2O4 Transparent MgAl2O4 spinel has been examined for potential applications as lamp envelopes, watch lenses, bullet-proof windows, pressure vessel windows, optical components and infrared windows. The hardness of spinel is 16.1 GPa which is slightly less than sapphire. Spinel has cubic structure which means that single crystals has no optical anisotropy. Phase diagram show substantial deviation from stoichiometric composition of MgAl2O4 at high temperature. Maximum transmittance in case of composition deviation in MgO-rich side is close to stoichiometric composition MgAl2O4 and not related to solid solution limits. In case of deviation in Al2O3 rich side grain size is maximal at the border Sp/Sp+Cor. Grain growth control is difficult and it is a key to the achievement of transparent spinel. One of possibilities to improve microstructure of MgAl2O4 is sintering with the aid of LiF. Calculated phase diagram of the MgO-Al2O3 system Transmittance of spinel vs. MgO content Average grain size vs. Al2O3 content in 1640-1685°C Thermal barrier coating Application of thermal barrier coating (TBC) enable to increase operating temperature of gas turbines and therefore increase their efficiency. TBC is complex multi-layered system consisting from top coat (ZrO2 partially stabilised by Y2O3 with tetragonal structure), bond coat (BC) chemically modified surface of Ni super-alloy and thermally grown oxide (TGO) which is dense layer of Al2O3 grown during service by thermal oxidation. Top coat is 125-250 mm layer of porous ZrO2 stabilised with 7 mass.% Y2O3 applied either by air-plasma spray(APS) or electron-beam physical vapour deposition (EB-PVD). Both processes lead to porous microstructure that benefit the thermal insulating efficiency and allow the coating to tolerate the thermal stress associated with the cycling temperatures in the engine. Bond coats are classified into two groups. (1) single phase b-(Ni,Pt)Al, applied by electrodeposition of Pt and subsequent aluminising by chemical vapour pressure deposition (CVD) and (2) overlay two-phase (g’+b/g) MCrAlY (M=Ni,Co), applied by low pressure plasma spray or EB-PVD. TGO is thin layer (<10 mm) of Al2O3 which play environmental protection role against oxidation and corrosion. Current technology is based on one thermal barrier material 7YSZ. The selection of this composition is based on longest durability. Higher Y content would improve insulating property, but durability is more important. Microstructure of EB-PVD coating 7YSZ Phase diagram of the ZrO2-Y2O3 system 7YSZ = 7 mass.% Y2O3 = 4 mol.% Y2O3 = 7.6 mol.% YO1.5 Te Fe T‘ F‘ Fluorite structure (F) Phase t‘ is tetragonal phase containing more Y than equilibrium t phase. Equilibrium tetragonal phase will transform to monoclinic phase on cooling, while t‘ is stable (non-transformable). Phase diagram of the ZrO2-Y2O3 system: stable and metastable phase boundaries Stabilization mechanism of metastable phases t‘ and t‘‘ Phase diagram of the ZrO2-Y2O3 system according to experimental data and calculations. At temperatures below 1200°C phase equilibrium can not be attained. Therefore experimental data (DTA, dilatometry, HT-XRD) are referred to diffusion-less transformations at temperatures below 1200°C. Metastable-stable phase diagram in the ZrO2-YO1.5 system [1996Yashima] New materials for TBC Experimental studies show that YSZ co-doped with other rare earth and pyrochlores RE2Zr2O7 demonstrate lower thermal conductivity than 7YSZ. 1. Co-doping of YSZ by rare earth oxides 2. Rare earth zirconates with pyrochlore structure 3. Other materials Stability of pyrochlores increases with radius of RE+3: La2Zr2O7 melts congruently, while other pyroclores transform to fluorite structure below liquidus. Temperature of transformation of pyrochlore to fluorite decreases with decrease of ionic radius. r(RE+3) Gd Sm Nd La Calculated ZrO2-rich part of ZrO2-REO1.5 phase diagrams along with T0-lines. Composition of phase should correspond to non-transformable range, i.e. it should not intersect T0(T/M) curve at ambient temperatures. With the ionic radius increase T0(F/T) are shifting to higher RE content. For La position of T0(T/M) substantially shifted to higher RE concentration thus making tetragonal phase transformable to TM disruptive transformation. The other important issue is stability of T’ phase against partitioning to equilibrium assemblage at high temperatures, because equilibrium tetragonal phase transforms to monoclinic phase on cooling. r(RE+3) Gd Sm Nd La Stability of RE stabilized ZrO2. Driving force for precipitation to stable phase equilibrium assemblage T+F: a RESZ RE=Gd, Sm, Nd, La; b- ZrO2-(Y1-xGdx)O1.5. Phase stability of singly doped zirconias (circles), and co-doped ZrO2-(Y0.5M0.5)O1.5 (diamonds). The curves present the maximum temperature before significant monoclinic formation was observed. The effect of different RE stabilizers on the resistance of TBC against partitioning to equilibrium assemblage and thus ensuing monoclinic transformation is shown in the figures. The maximal driving force is for La. The equilibrium tetragonal phase resulting from partitioning of T‘/F‘ is transformable and jeopardize durability of coating. Co-doped materials do not show partitioning at temperature below 1500°C except for La co-doped ZrO2. Durability of 7YSZ is higher. Compatibility of TBC top coat with TGO 7YSZ is chemically compatible with Al2O3. However thermal expansion misfit between Al2O3 and 7YSZdecrease durability. For new candidate materials chemical compatibility with Al2O3 should be checked. Experimental results for diffusion couple between Gd2Zr2O7 and Al2O3 heat treated at 1200°C [2005Leckie]. In the ZrO2-RE2O3 systems RE2Zr2O7 with pyrochlore structure forms for RE=La-Gd and d-RE4Al3O12 for RE=Y, Er-Lu. In the RE2O3Al2O3 systems REAl11O18 with b-alumina structure forms for RE=La, Nd (b-alumina for Nd at high T) , REAlO3 perovskite for RE=Nd, Sm-Gd and RE3Al5O12 garnet for RE=Y, Er-Lu. Phase diagrams show that RE2Zr2O7 should react with Al2O3 (TGO). Therefore pyrochlores can be used as TBC only by incorporating diffusion barrier (usually 7YSZ). 7YSZ is compatible with Al2O3 since no compounds appear at the interface. Phase diagram shows that YSZ compatibility limit (X*) at 1200°C is 20 mol. % YO1.5 when YAG appears in equilibrium with fluorite and Al2O3. Compatibility limit of GdSZ is 32 mol.% GdO1.5 when GAP (perovskite) appears in equilibrium with fluorite and Al2O3. The lowest compatibility limit for LaSZ is equal to ~5 mol.% LaO1.5, when b-alumina appears in equilibrium with tetragonal phase and Al2O3. Compatibility of TBC with TGO and phase diagrams of the ZrO2-RE2O3-Al2O3 systems Other additives of YSZ for TBC applications The TiO2 additions to YSZ enhances the toughness of YSZ and its durability of coating. The TiO2 is one of small number of dopants that increase tetragonality of zirconia solid solutions without compromising its phase stability. Codoping with Y+3 and Ti+4 yields the compositions that do not transform to monoclinic phase even after decomposition of metastable solid solution into T+F equilibrium assemblage. F F The ZrO2-Y2O3-Ta2O5 system presents several properties attractive for TBC application. The solubility of Ta+5 in ZrO2 is quite modest, but codoping with Y+3 show synergism and solubility of YTaO4 is much higher than Y+3 and Ta+5 alone. The YTaO4 rich composition of tetragonal phase are stable up to 1500°C and non-transformable to monoclinic phase upon cooling. In addition Y+Ta stabilized compositions within non-transformable tetragonal phase exhibits toughness slightly above than 7YSZ that improves their durability as TBC. Concluding remarks about novel materials for TBC 7YSZ is presently used as TBC. The issue is ageing effect on phase stability at temperatures above ~1200°C and necessity to decrease thermal conductivity. The requirements to the new candidate materials are: (1) high melting point; (2) no phase transformations in the range between room temperature and operation temperature; (3) low thermal conductivity; (4) chemical inertness; (5) thermal expansion match with metallic substrate and TGO; (6) good adherence to metallic substrate and TGO; (7) low sintering rate of porous microstructure. To reduce thermal conductivity two groups of candidate materials were considered: RE codoped YSZ and RE zirconates with pyrochlore structure. Multiple co-doping with one smaller cation (Yb, Sc) and one larger (La, Nd, Sm, Gd). The defect nano-cluster system arises which contribute to phonon scattering and reduction of thermal conductivity. Pyrochlores have many advantages such as lower thermal conductivity, high microstructural stability. The disadvantages are low thermal expansion coefficient and therefore larger misfit with TGO and reaction with TGO forming aluminates. The double layer concept can be a solution of these problems: pyrochlore can be used as top layer to reduce thermal conductivity and 7YSZ as next layer for better compatibility with TGO. Testing of double layer coating indicated better durability than 7YSZ during cycling at 1300°C [2004Vassen]. Additional issues arise when considering environmental effect on novel TBC. Many of suggested materials exhibit lower erosion resistance. The other concerns are related to attacks of molten silicates. Molten Ca-Mg-alumino-silicates (CMAS) appear to readily penetrate all ZrO2 based compositions. Understanding of reactions between TBC and CMAS is important to develop TBC resistance to CMAS attacks.