File - CIVIL ENGINEERING INFO

SHOTCRETE TECHNOLOGY

What is shotcrete?

How is it different from conventional concrete?

Constituent materials

Equipment

Properties

Factors affecting adhesion

Advantages

Drawbacks

Applications

Precautions

Conclusion

Shotcrete is the sprayed concrete.

Shotcrete process uses compressed air to convey the concrete mix through delivery hose to project the material onto the sprayed surface under high velocity .

Shotcreting can be done in dry mix and wet mix processes.

Simultaneous placing and compaction

Minimum to no formwork requirement

Dense, homogenous, strong and water proof compared to conventional

* concrete placing methods.

Traditional portland cement

Additions:

1.PFA

2.GGBS

3.CSF

Aggregates

Admixtures:

1.accelerators

2.super plasticizers

3.hydration control admixtures

Fibres

Steel reinforcement

Curing agents

Low water/cement ratio

High strength and rapid strength gain

High density and low permeability

Enhanced adhesion and high bond strength

Early setting and better finish

• Geometrical variation of the surface

• Nozzle angle to surface

• Nozzle distance to surface

• Viscosity of the concrete

• Thickness of the current layer of concrete on the surface

• Velocity of flow of the concrete

• Accelerant dose

Reduction in formwork cost

Limitless shape possibilities

Superior freeze and thaw resistance

Reduction of drying shrinkage

Can be used for work on irregular surfaces

Minimal curing

Ease of access

Economical

Time saving

Sustainable process

• High initial cost

• High skill requirement

• The dust can cause health hazard to construction workers

Water Retaining Structures

Sea and river walls

Reservoirs and dams

Swimming pools

Water towers

Canal linings

Irrigation and drainage channels

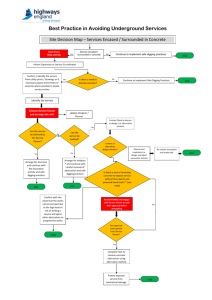

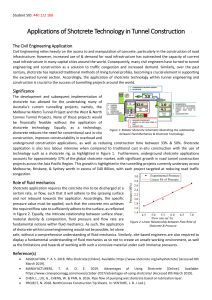

Underground Construction

Tunnel linings

Storage reservoirs

Mining and excavation

Underpinning

Foundation stabilization

Protective Coatings

Fire protection to structural steelwork

Refractory linings

Cracks repair

Rock and soil stabilization

Bridges and housing

Other Constructions

Shell roofs and domes

Retaining walls

Silo structures

Blast proof structures

Bank vaults

Shoring for excavation

Sculptures and texturing

PRECAUTIONS

Shotcrete should not be applied on dry, dusty or frozen rock surfaces. The work surface should be sprayed with an air water jet before shotcreting.

The distance between the work surface and nozzle should be 1-1.5 meters and the nozzle should be held perpendicular to the surface for effective shotcreting .

The workmen should wear protective mask while working.

PRESENTATION BY: