AS Systems SoW

advertisement

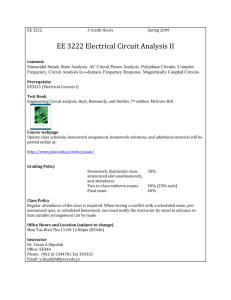

Sec 1 Sec 2 Sec 3 Sec 4 CRF 28 April 2014 21 April 2014 14 April 2014 07 April 2014 31 March 2014 24 March 2014 17 March 2014 10 March 2014 03 March 2014 24 February 2014 17 February 2014 10 February 2014 03 February 2014 27 January 2014 20 January 2014 13 January 2014 06 January 2014 30 December 2013 23 December 2013 16 December 2013 09 December 2013 02 December 2013 25 November 2013 18 November 2013 11 November 2013 04 November 2013 28 October 2013 21 October 2013 14 October 2013 07 October 2013 30 September 2013 23 September 2013 16 September 2013 09 September 2013 02 September 2013 Week Beginning AS Systems and Control 2013_14 Bedford Modern School AQA AS Learning Through Designing and SYST 1 Making AS Systems SoW – AWR Lessons Module LO Tasks Resources HW Electronic System Components: Input Transducers A minimum of one electronic input transducer which is activated by each of the following: • sound • light • pressure • rotary movement • linear movement • strain • moisture A minimum of two alternative methods of amplifying each of the following: • current • voltage Discuss and define transducers. Physical examples of transducers. Complete shared slides of transducers types 1 Amplifiers 2 1 Comparators 2 Electronic Processing Systems: A minimum of one method of comparing: • different input voltages • digital inputs The use and combination of 2, 3 and 4 input gates Google apps accounts set up Google apps task to share research and development of information slides for each actuator listed Discuss the use of transistors and transistor types. Discuss the application of Op-amps. Makes notes on the use of transistor and op-amp circuits and operation. Model and test examples Look at Op-amp examples as comparators. Build in feedback resistors and test voltages Review logic symbols and truth tables. Sample op amp circuit Op-amps in Circuit Wizard Breadboards Components Read section on Opamps in text. Inc positive and negative feedback. Q4. Jun 2010 Breadboards and components Past paper question on basic sensing circuits. Q1 Jan 04 Past paper question on Logic circuits Circuit Wizard Blank tables of logic symbols and Logic L atches 1 Counters 3 Timers 2 with the following functions: • NOT • AND • OR • NAND • NOR • XOR Understand the use of NAND gates to build any other gate. Recognise the need to avoid Floating gates when using ICs. A minimum of two alternative methods of setting and latching the state of an output for a specific input A minimum of two alternative methods of counting input pulses to produce: • a decade output • a binary output • the correct coding to operate a 7 segment display A minimum of two alternative methods of producing: • a single output pulse of Complete table of symbols and truth tables. Complete table of combinational logic Build logic using NAND gates on circuit wizard. Breadboard logic circuits truth tables Blank tables of combinational logic Breadboards AND NAND gate ICs and components design. Q4. Jan 04 Discuss the use of Thyristors, DPDT relay and transistors and logic gates to create latches. Model and test latching on Circuit Wizard Notes on flip flops and demo circuits. Develop binary count Develop decoded decade counter to give 7 segment display for car rev counter Circuit Wizard Build relay and Thyrsitor latching circuits using circuit Wizard and describe operation 4026B Decoder CC 7 seg displays Read through section of different flip flop types in text book . Review and notes on the operation of the 555 timer for monostable and astable function. Review Example 555 circuits from circuit wizard. Model 555 on breadboard Build a decoder capable of counting pulses from an astable counter for a Decoders 1 Output Transducers 2 Interfacing System Blocks 1 a set duration • a string of output pulses with a set mark/space Ratio calculations. Use of logic gates to create a monostable output one minute time period (circuit wizard) A minimum of one method of decoding a 4 bit binary Input to: • drive a 7 segment display • produce a decade output A minimum of one electronic output transducer for each of the following: • linear motion • rotary motion • precise angular movement • heat • light • sound • amplification • magnetism The selection of suitable interfaces to establish connections in electrical, electronic and mechanical systems. e.g. motors, solenoid valves, relays, Review of homework circuits for counter. Develop into working breadboard circuit Astable and monostable breadboards. 7 segment displays 4026 and 4093 ICs Past paper qu. (runner and timing or counting pulses) Google apps task to share research and development of information slides for each actuator listed Physical examples of transducers. Complete shared slides of transducers types Review of transistor types bipolar, MOSFET. Review use of Relays and solenoids and types. Review use of motor types, inc. DC, Stepper and Servo. Discussion on applications Examples of transistors, relays and motors. Google apps accounts set up Read and make notes/table of transistor types and applications, inc Darlington Pair. Notes on motor types, describing 2 amplifiers and possible use in projects Information Technology: Program The purpose of a program – a logical set of instructions Construction Techniques A practical knowledge of: • two methods of modelling an electronic circuit • two methods of producing a PCB System Diagrams Input → Process → Output → Feedback • definition of a system • system boundaries • sub-systems • system components • sensors • input transducers • signal conditioners • timers • amplifiers • comparators • counters • latches • flip flops Review example flowcharts Example flowchart programs and and applications. Discuss project boards input requirements (held low) and digital/analogue inputs. Discuss interfacing Discuss alternatives to Examples of other modelling breadboarding and the use techniques (vero, alpha) of veroboard. Discuss Etch tank set up and ready to use. advanatges/disadvantges of simulations and breadboards and Alpha boards Review PCB production process (ties in with production for project) The main elements of this section of the spec will be covered through the development of the students own personal project in the “Learning by Making” unit of the course (2) Combinations of practical modelling, investigation, feasibility studies and manufacture will be evidenced within the supporting slide show. See timeline for Learning Through Design and making at the front of this document 1 System Definitions System Building Blocks their appropriate applications and contrasts. Create a flowchart capable of counting pulses from a bike wheel to give an rpm count for one minute. Create a summary table of advantages/disadvan tages of each modelling method. OR past paper question Systems and Control: Application of Control Systems Input/Output Devices • logical operators • output transducers • programmable devices The matching of control systems to specific industrial applications – consideration of mechanical, electrical, electronic, programmable logic units and microcontrollers Matching the method of input/output to the application Selection of appropriate input/output transducers for specific applications Basic Principles • force • motion • movement • velocity • pressure • voltage • current • resistance • power • signals • positive and negative going pulses • positive and negative The main elements of this section of the spec will be covered through the development of the students own personal project in the “Learning by Making” unit of the course (2) Combinations of practical modelling, investigation, feasibility studies and manufacture will be evidenced within the supporting slide show. Mechanical Processes Tribology Transmission Amplification edge triggering • mark/Space ratio • amplitude • frequency A minimum of two mechanical systems to provide each of the following transmissions of motion: • rotary to rotary (parallel shafts) • rotary to rotary (perpendicular shafts) • rotary to linear, linear to rotary • rotary to reciprocating • reciprocating to rotary • rotary to oscillatory • oscillatory to rotary The systems should be capable of amplifying the movement or force of the input Useful and non-useful friction – methods of reducing friction e.g. clutches, braking systems, bearings, lubricants Signal – electricity – heat – motion The amplification of: • force The main elements of this section of the spec will be covered through the development of the students own personal project in the “Learning by Making” unit of the course (2) Combinations of practical modelling, investigation, feasibility studies and manufacture will be evidenced within the supporting slide show. Data Manipulation Resistant Materials: 3 • motion • movement • velocity • pressure • voltage • current • power • signal Information, storage, retrieval and manipulation of data so it can be interrogated, modified and presented A general understanding of the following groupings of materials: • common ferrous and non-ferrous metals including alloys • common thermoplastics and thermosetting plastics • common hardwoods, softwoods and manmade boards • smart materials created to provide specific properties. e.g. thermoplastic sheet, smart wire A general understanding The main elements of this section of the spec will be covered through the development of the students own personal project in the “Learning by Making” unit of the course (2) Combinations of practical modelling, investigation, feasibility studies and manufacture will be evidenced within the supporting slide show. Class discussion and sharing of samples of materials and market forms Wood, metal, plastic, smart material samples all available in store 3 homeworks over 3 weeks identifying and recording groups, names, properties and applications of each category of the working properties, commonly available market forms and suitable finishes for enhancement and protection Comparative Properties 3 Comparative Testing Sufficient detail to allow products/systems to be manufactured Discussion and notes on definitions of testing methods, sample size and definitions of properties Test samples, DVD views of sample testing and sample types. Examples of typical data and its applications Past paper question Common methods of workshop testing to compare the properties of materials e.g. tensile strength, hardness, toughness Understanding of standard testing methods and data Industrial and Commercial Practices: 2 Industrial processes Understanding of how familiar processes used in school are related to those used in the industrial context, especially with reference to batch and mass production. e.g. sand Notes and discussion on production levels. Design considerations for production levels. Sketches of project design altered to suit batch production casting, die casting, vacuum forming, PCB production 3 Product/Systems Manufacturing: Wastage Addition/Fabrication 2 Hand and machine methods of shaping commonly available resistant materials by wastage A minimum of four: • hand methods • machine methods • CAM methods Permanent fabrication techniques suitable for wood A minimum of two: • mechanical methods • chemical methods Permanent fabrication techniques suitable for metal Workshop based. Demo use of lathes, milling m/c. Review use of cutting and filing techniques. Review use of laser and demo use of CNC router. Lathes and tools, MC and tools, material samples Workshop based to discuss and look at practical techniques for each material. Demo and practical exercises to include Screw types Adhesives Welding/brazing Rivets and types Nuts and bolts and applications Materials and components to suit Use free/lunchtime demo. All readily available in store. to practise and try out some of the techniques demonstrated keeping samples. A minimum of two: • thermal methods • mechanical methods Permanent fabrication techniques suitable for plastic Discuss and identify the difference between permanent and temporary joining. Develop skills through practise in lunchtime/after school Past paper question A minimum of two: • thermal methods • mechanical methods • chemical methods Temporary fabrication techniques suitable for wood, metal and plastic A minimum of three mechanical methods Redistribution /Deformation • a minimum of three redistribution/deformatio n processes suitable for metals Demo of sand casting and discuss alternatives. Notes and diagrams of casting, pressing, forging • a minimum of three redistribution/deformatio n processes suitable for plastics Review of details of vacuum forming and demo as necessary. Discuss alternatives to include injection moulding and extrusion, 3D printing Notes and diagrams on vac forming, injection moulding and extrusion 3 • a minimum of two redistribution/deformatio n processes suitable for woods Aids to Production 1 Prototyping, modelling, use of jigs, templates, Demo use of the air bag for laminating (could fit in with other lesson being delivered to year 11) Demo examples and assess use through project Notes and diagrams on bag press and steam bending CAM and CIM