Chapter4 Imperfections: Point and Line Defects

advertisement

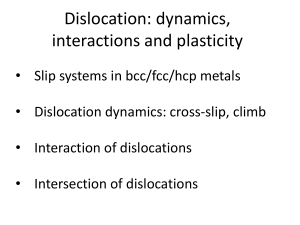

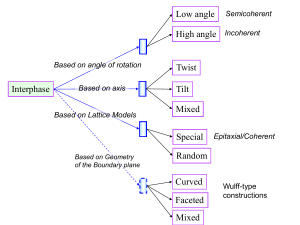

Chapter 4 Imperfections: Point and Line Defects Dimensional Range for Different Classes of Defects Stress Required to Shear a Crystal Theoretical Shear Strength of Some Materials Point Defects Atomic point defects. Two most common point defects in compounds: Schottky and Frenkel defects. Point Defects Interstices in FCC structure. (a) Octahedral void. (b) Tetrahedral void. Interstices in the BCC structure. (a) Octahedral void. (b) Tetrahedral void. Interstices in the HCP structure. (a) Octahedral void. (b) Tetrahedral void. Formation of Point Defects Formation of point defects by the annihilation of dislocations. (a) Row of vacancies. (b) Row of interstitials. Shear stress-Shear Strain Curves for Aluminum Single Crystal Shear stress-versus-strain curves for aluminum single crystals. The crystallographic orientation is shown in the stereographic triangle. (Adapted with permission from A. H. Cottrell, Phil. Mag., 46 (1955) p. 737.) Radiation Damage Seeger model of damage produced by irradiation. P indicates the position where the first “knock-on” terminates. (Reprinted with permission from A. Seeger, in Proc. Symp. Radiat. Damage Solids React., Vol. 1, (Vienna, IAEA, 1962) pp. 101, 105.) Voids formed in nickel irradiated using 400 keV 14N2+ ions to a dose of 40 dpa at 500 ◦C; notice the voids with polyhedral shape; dpa = displacements per atom. (Courtesy of L. J. Chen and A. J. Ardell.) Radiation Damage Stress–strain curves for irradiated and unirradiated Zircaloy. (Adapted with permission from J. T. A. Roberts, IEEE Trans. Nucl. Sci., NS22, (1975) 2219.) Radiation Damage Stress-free dilation in AISI 316 steel (20% cold worked). (Adapted with permission from J. T. A. Roberts, IEEE Trans. Nucl. Sci., NS-22, (1975) 2219.) Dependence of fast neutron-induced dilation in stainless steel (Fe–Cr–Ni) as a function of Ni and Cr amounts. (Adapted with permission from W. B. Hillig, Science, 191 (1976) 733.) Line Defects (a) Rug with a fold. Caterpillar with a hump. Edge and Screw Dislocations Arrangement of atoms in an edge dislocation and the Burgers vector b that produces closure of circuit ABCDE. Arrangement of atoms in a screw dislocation with “parking garage” setup. Notice car entering garage. Edge and Screw Dislocations . (a) Perfect crystal. (b) Edge dislocation. (c) Screw dislocation. Plastic Deformation Plastic deformation of a crystal by the movement of a dislocation along a slip plane. Shear Produced by Dislocation Movement Mixed Dislocation Mixed dislocation obtained from cutand-shear operation; notice the angle between b and dislocation line. Dislocations in Metals (a) Titanium. (Courtesy of B. K. Kad.) (b) Silicon. Dislocations in Al2O3 and TiC Dislocations in (a) Al2O3 and (b) TiC. (Courtesy of J. C. LaSalvia.) Dislocation in Molybdenum Atomic resolution transmission electron micrograph of dislocation in molybdenum with a Burgers circuit around it. (Courtesy of R. Gronsky.) Square Dislocation Loop Elliptic Dislocation Loop Elliptic dislocation loop. (a) Intermediate position. (b) Final (sheared) position. (c) TEM of shear loop in copper. (Courtesy of F. Gregori and M. S. Schneider.) Prismatic Loop Prismatic loop produced by the introduction of a disk into metal. (a) Perspective view. (b) Section AAAA. (c) Section BBBB. Movement of Dislocation Slip produced by the movement of dislocation. (a) Positive and negative edge dislocations. (b) Positive and negative screw dislocations. Expansion of a Dislocation Loop Stresses due to Dislocations Screw Dislocation Edge Dislocation Stress Fields Around a Edge Dislocation Stress fields around an edge dislocation. (The dislocation line is Ox3), (a) σ11; (b) σ22; (c) σ33; (d) σ12. (Adapted with permission from J. C. M. Li, in Electron Microscopy and Strength of Crystals, eds. G. Thomas and J. Washburn (New York: Interscience Publishers, 1963).) Dislocation Array Schematic representation of an idealized dislocation array (a) in two dimensions (b) in three dimensions; note that dislocations on three perpendicular atomic planes define a volume V. Bending of a Dislocation Dislocations in an FCC Crystal Peach-Koehler Equation Decomposition of Dislocation Decomposition of a dislocation b1 into two partial dislocations b2 and b3, separated by a distance d0. Stacking Fault Energies of Some Metals Stacking Fault and Partial Dislocations Short segment of stacking fault in AISI 304 stainless steel overlapping with coherent twin boundary. Differences in the nature of these defects are illustrated by fringe contrast differences. Dislocations in AISI 304 stainless steel splitting into partials bounded by short stacking-fault region. Partials spacing marked as d. (Courtesy of L. E. Murr.) Effects of Stacking-Fault Energy on Dislocation Substructure Effect of stacking-fault energy on dislocation substructure. (a) High-stacking-fault-energy material (pure copper); (b) Low-stacking-fault-energy material (copper–2 wt% aluminum). Both materials were laser-shock compressed with an initial pressure of 40 GPa and pulse duration of 3 ns. (Courtesy of M. S. Schneider.) Frank or Sessile Dislocations Frank or Sessile dislocations. (a) Intrinsic. (b) Extrinsic. Cottrell –Lomer and Stairway Dislocations Cottrell–Lomer lock. Stairway dislocation. Important Planes in HCP Structure Basal, pyramidal, and prism plane in HCP structure. Temperature for Macroscopic Plasticity in Some Ceramics Slip Systems and Burgers Vectors in Some Ceramics Expressions for Energy of Dislocation Screw Dislocation Edge Dislocation General Form Basal Plane in Al2O3 Elastic Energy for Dislocations in Ceramics Dislocations in Sapphire (a) Dislocations, dipoles, and loops in sapphire. (b) Interaction between dislocations in sapphire. (From K. P. D. Lagerdorf, B. J. Pletka, T. E. Mitchell, and A. H. Heuer, Radiation Effects, 74 (1983)).87 Dislocations in Titanium Diboride Hexagonal array of dislocations in titanium diboride. (Courtesy of D. A. Hoke and G. T. Gray.) Stacking faults in GaP. (Courtesy of P. Pirouz.) Homogeneous Nucleation of Dislocations Grain Boundary as a Source of Dislocations Emission of dislocations from ledges in grain boundary, as observed in transmission electron microscopy during heating by electron beam. (Courtesy of L. E. Murr.) Effect of Oxide Layer on the Tensile Properties of Niobium Effect of oxide layer on the tensile properties of niobium. (Reprinted with permission from V. K. Sethi and R. Gibala, Scripta Met. 9 (1975) 527.) Frank-Read Mechanism Formation of dislocation loop by the Frank–Read mechanism. Dislocation Source: Cross Slip Frank–Read source formed by crossslip. Epitaxial Growth Epitaxial growth of thin film. (a) Substrate. (b) Start of epitaxial growth. (c) Formation of dislocations. Dislocation Pileups Pileup of dislocations against a barrier. Pileup of dislocations against grain boundaries (or dislocations being emitted from grain boundary sources?) in copper observed by etch pitting. Dislocation Interactions (a) Edge dislocation traversing “forest” dislocation. (b) Screw dislocation traversing “forest” dislocations. Kinks and Jogs in Dislocations (a) Kink and jog in edge dislocation. (b) Kink and jog in screw dislocation. Loop being pinched out when jog is left behind by dislocation motion. Orowan’s Equation k b Peierls-Nabarro Stress (a) Movement of dislocation away from its equilibrium position. (b) Variation of Peierls–Nabarro stress with distance. (Reprinted with permission from H. Conrad, J. Metals, 16 (1964), 583.) Overcoming of Peierls Barrier Overcoming of Peierls barrier by Seeger kink pair mechanism. (a) Original straight dislocation. (b) Dislocation with two kinks. (c) Kinks moving apart. Temperature Effect on Young’s Modulus Effect of temperature on Young’s modulus. (Adapted from J. B. Wachtman Jr.,W. E. Tefft, D. G. Lam, Jr., and C. S. Apstein, J. Res. Natl. Bur. Stand., 64A (1960) 213; and J. Lemartre and J. L. Chaboche, Mechanics of Solid Materials, Cambridge: Cambridge University Press, 1990, p. 143.) Flow Stress as a Function of Temperature Flow stress as a function of temperature for (a) an idealized material, (b) BCC metals, and (c) FCC metals. Notice the greater temperature dependence for Ta and Fe (BCC). Dislocations on Film-Substrate Interface Stresses and dislocations generated at film-substrate interface; (a) Film and substrate with different lattice parameters; (b) elastic (coherent) accommodation of strains by film; (c) elastic + dislocation (semi-coherent) accommodation of strains at a film thickness greater than hc.(Adapted from W. D. Nix, Met. Trans., 20A (1989) 2217.) Critical Film Thickness vs. Atomic Fraction of Ge Critical film thickness as a function of misfit strain; the greater fraction Ge, the greater the misfit stain and the smaller hc. Predictions from van der Merwe Matthews theory; measurements from J. C. Bean, L. C. Feldman, A. T. Fiory, S. Nakahara, and I. K. Robinson, J. Vac. Sci. Technol. A, 2 (1984) 436. (Adapted from W. D. Nix., Met. Trans., 20A (1989) 2216.) Misfit Dislocation Generation Mechanisms of misfit dislocation generation; (a) Freund mechanism in which a “threading” dislocation preexisting in substrate lays over interface creating misfit dislocation; (b) Nix mechanism, in which a surface source creates half-loops that move toward interface.