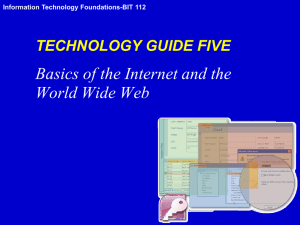

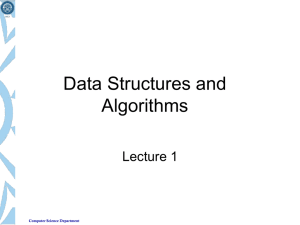

TES ADT Growth Rate Into Channels and Corners

advertisement

Crystallization of TES ADT in Constrained Channels Abby Grosskopf, Anna Hailey, Lynn Loo Loo Lab Group: Polymer and Organic Electronics Laboratory Princeton University Background Information Organic Semiconductor: An organic material with an electrical conductivity Benefits of using organic semiconductors over inorganic semiconductors: - Solution-processable - Inexpensive to fabricate - Suitable for large area processing Thin films comprising organic molecules have promising applications, such as organic thin film transistors, and solar cells. http://www.sigmaaldrich.com/technical-documents/articles/materialmatters/organic-materials.html http://www.sunnysolarlightgarden.com/solar-yard-lights-work/ Crystallization of TES ADT TES ADT is a solution-processable organic semiconductor. TES ADT undergoes spherulitic growth when spin coated from 2 wt% solution in toluene then exposed to 1,2-dichloroethane vapor. Spin-coat from 2 wt% solution in toluene Expose to 1,2-dichloroethane vapor1 as-spun film crystallized film Lee, Stephanie. (2012). Processing-Structure- Function Relationships In Solution-Processed , Organic-Semiconductor Thin Films for Transistor Applications. Ph.D. Thesis. Princeton University.: US. Graphics thanks to Anna Hailey TES ADT and Guiding Crystallization • Utilizing differences in TES ADT growth rate on SIO2 vs PFBT-treated Au, growth can be specified along channels. • Guiding crystallization allows us to pattern TES ADT into predefined pathways which can potentially have applications in organic electronics. Lee, Stephanie. (2012). Processing-Structure- Function Relationships In Solution-Processed , Organic-Semiconductor Thin Films for Transistor Applications. Ph.D. Thesis. Princeton University: US. My Project What are the limits to guiding growth of TES ADT on patterned substrates? What is the smallest feature size that we can pattern with TES ADT? By understanding more about the growth of TES ADT in channels, we hope to pattern electronics in more elaborate and efficient ways to create new devices and save energy. Haataja’s Group Predictions Sri Muralidharan’s PhD Thesis: V denotes the growth rate, M denotes mobility , Γ denotes interfacial forces, E denotes the bulk driving force of crystallization, κ denotes interfacial curvature, and w denotes channel width. Muralidharan, Srevatsan. (2012). Continuum Studies of Microstructure Formation in Metallic and Organic Thin Films. Ph.D. Thesis. Princeton University: U.S. TES ADT Growth in Channels 1000um TES ADT Growth into Corners 1000um Alta Fang’s Predictions No TES ADT Leaking Out of Corner: TES ADT Leaking Out of Corner: Instantaneous Velocity vs. 1/(width of pattern at growth front) The crystal growth outside of the pattern will always drag the crystal growth front up and over the corner. Results: Different Corners Growth Rate of TES ADT Growth Into Corners ( Bulk Driving Force May Increase) 20 18 16 Speed (um/s) 14 12 PFBT 10 Corner 1 8 Corner 2 Corner 3 6 4 2 0 0 0.1 0.2 0.3 0.4 Inverse Width (1/um) Critical Widths: 1.7 um, 2.0 um, 2.5 um 0.5 0.6 0.7 Results: Channel and Corner Data Combined TES ADT Growth Rate Into Channels and Corners 25 Growth Rate (um/s) 20 15 PFBT Corners 10 Channels 5 0 0 0.1 0.2 0.3 0.4 Inverse Width (1/um) 0.5 0.6 0.7 Using the predicted equation, the averaged critical channel width is 2 um. Closing Remarks - Learned new lab techniques, data analysis skills, and the fundamentals of day-to-day laboratory research - Gained a new perspective on the vast amount of applications of chemical engineering in scientific research - Looking forward to using what I learned this summer in future independent work! Special Thanks to: