Mass Balance

advertisement

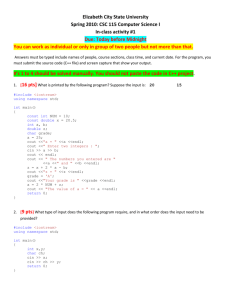

Mass Balance Benno Rahardyan FTSL-ITB Mass Balance The law of conservation of mass states that mass can neither be produced nor destroyed Mass at time t + dt = mass at time t + mass that entered from t to t + dt - mass that exited from t to t + dt + net mass of chemical produced from other compounds by reactions between t and t + dt Unit : mass • It is usually more convenient to work with values of mass flux the rate at which mass enters or leave the systems. (mass at time t + dt) / dt = (mass entering from t to t+dt) / dt - (mass exiting from t to t+dt) / dt + (net chemical production from t to t+dt)/dt Unit : mass/time Mass accumulation rate = Mass flux in – mass flux out + net rate of chemical production or dm/dt = min – mout + m reaction The control volume • A mass balance is only meaningful in terms of specific region of space, which has boundaries across which in terms min and mout are determined. • This region is called the control volume. • control volume has boundaries over which min and mout can be calcultated. CMFR • Completely mixed flow reactor control volume • Example : CSTR (continously stirred tank reactor) dm/dt = d (VC) / dt m : mass V : volume C : concentration • Steady state : condition that no longer change with time. • The concentration and hence the mass within the control volume remains constant. dm/dt = 0 When the mass in the control volume vary with time mass balance will be non steady state Discussion • For each of the following mass balance problems, determine whether a steady state or non steady state mass balance would be appropriate • A mass balance on chloride (Cl-) dissolved in a lake. Two rivers bring chloride into the lake, and one river removes chloride. No significant chemical reactions occur, as chloride is soluble and non reactive. What is the annual average concentration of chloride in the lake? • A degradation reaction within a wellmixed tank is used to destroy a pollutant. Inlet concentration and flow are held constant, and the system has been operating for several days. What is the pollutant concentration in the effluent, given the inlet flow and concentration and the first-order decay rate constant? • The source of pollutant in previous problem is removed, resulting in an isntantaneous decline of the inlet concentration to zero. • How long would it take until the outlet concentration reaches 10% of its initial value? • Max flux in min = Q in x C in m=QxC mass/time = volume/time x mass/volume • Max flux out mout = Q out x C out m out = Q out x C mass/time = volume/time x mass/volume • Net rate of chemical reation – Net rate of production of a compound from chemical or biological reactions. – Mass/time – Positive or negative – Usulally expressed in terms of concentration – Mrxn = V x (dC/dt) • Conservative compound – dC/dt = m reaction = o • Zero order decay : the rate of loss of the compound is constant – dC/dt equals – k – Mrxn equals - Vk • First order decay – Rate of losses of the compound is directly proportional to its concentration – dC/dt equals – kC, for such compound Mrxn equals - VkC approaches • Draw a schematic diagram of situation • Write a mass balance equation dM/dt = Min – Mout + Mrxn • Determine whether the problem is steady state or not (dm/dt = 0) or non steady state (dm/dt = V dC/dt) • Determine whether the compound being balanced is concervative (mrxn = 0) or non conservatives (mrxn must be determined based on the reaction kinetics). Batch Reactor • The reactor that has no inlet or outlet is termed as batch reactor. Min = 0 and M out = 0 dM/dt = M rxn VdC/dt = V (dC/dt) (reaction only) dC/dt = dC/dt (reaction only) Example • First order decay r = - kC dC/dt = - kC or Ct / Co = e-kt Plug Flow Reactor • Model the chemical transformation of compound as they are transported in systems resembling pipes. • Because the velocity (v) of the fluid in the PFR is constant, time and downstream distance x are interchangeable and t = x/v dm/dt = min – mout + mrxn V(dC/dt) = 0 – 0 + V(dC/dt) reaction only Min and mout are set equal to zero because there is no mass exchange across the plug boundaries. In the case of first order decay V(dC/dt) reaction only = - VkC and VdC/dt = - VkC Which results in Ct/Co = exp (-kt) In PFR or length L t = L/ v = L x A/Q Ct/Co = exp (-kV/Q) Retention time and other expression form V/Q Retention time, detention time, and residence time t = V/Q Example of Steady State CMFR with Conservative Chemical Mixing • A pipe from a municipal wastewater treatment plant discharges 1.0 m3/s of poorly treated effluent containing 5.0 mg/L of phosphorus compunds *reported as mgP/L) into a river with a upstream flow rate of 25 m3/s and a background phosphorus concentration of 0.010 mgP/l. What is the resulting concentration of phosphorus (in mg/L) in the river just downstream of the plant outflow? dm/dt = min – mout + mrxn = rQin - rQout + 0 Qin =Qout Qd=Qu+Qe = 26 m3/s 0= (CuQu+CeQe) – CdQd + 0 Cd =(CuQu+CeQe) / Qd =(0.010 mg/L)(25 m3/s)+(5.0 mg/L)(1.0m3/s) ------------------------------------------------------------26 m3/s Example Steady State CMFR with First Order Decay • The CMFR is used to treat an industrial waste product, using a reaction that destroys the pollutant according to first order kinetics, with k = 0.216/day. The reactor volume is 500 m3, the volumetric flow rate of the single inlet and exit is 50 m3/day and inlet pollutant concentration is 100 mg/L. What is the outlet concentration after treatment? dm/dt = min – mout + mrxn 0 = QCin-QC-VkC C = Cin x Q / (Q + kV) C = Cin x 1 / (1 + kV/Q) 100 mg/L x 50 m3/day C = ---------------------------------50 m3/day + (0.216/day)(500 m3) Example Non Steady State CMRF with First Order Decay • The manufacturing process that generates the waste in previous example has to be shut down, and starting at t=0, the concentration Cin entering the CMFR is set to 0. What is the outlet concentration as a function of time after the concentration is set to 0? How long does it take the tank concentration to reach 10% of its initial, steady-state value? dm/dt = min – mout + mrxn VdC/dt = 0- QC- kCV dC/dt = - (Q/V + k)C To determine C as a function of time [Int Co Ct] (dC/dt) = ln (C)- ln (Co) [Int 0t] - (Q/V + k)C = - (Q/V + k)t ln (C/Co) = - (Q/V + k)t Ct/Co = exp [- (Q/V + k)t] • Ct = 32 mg/L x exp[- 50 m3/day/500 m3 + 0.216/day)t] = 32 mg/L x exp (-0.316/day x t) Ct/C0= 0.10 0.10 = exp (-0.316/day x t) ln(0.10) = -2.303 = (-0.316/day x t) t = 7.3 days Non Steady State CMFR Conservative Substance • The CMFR reactor is filled with clean water prior to being started. After start up, a waste stream containing 100 mg/L of concervative pollutant is added to the reactor at a flow rate of 50 m3/day. The volume of the reactor is 500 m3. What is the concentration exiting the reactor as a function of time after it is started? dm/dt = min – mout + mrxn VdC/dt = QCin-QC + 0 dC/dt = -(Q/V)(C-Cin) y = (C-Cin) dy/dt = dC/dt – d(Cin /dt). Cin constant d(Cin /dt) = 0 dy / dt = dC/dt dy/dt = - Q/V x y [int y(0) y (t) ] dy/y = ln (y(t)/ y(0) ) [int (0) (t) ] – Q/V dt = - (Q/V) t (y(t)/ y(0) ) = exp (- (Q/V) x t) C - Cin = - Cin exp (- (Q/V) x t) C = Cin (1+ exp (- (Q/V) x t)) t : exp (- (Q/V) x t) 0 C Cin Example Required Volume in PFR • Determine the volume required for a PFR to obtain the same degree of pollutant reduction as in first example. Assume that the flow rate and first order decay rate constant are unchanged (Q= 50 m3/day, k = 0,216/day) Cout/Cin = 32/100 = 0.32 Cout/Cin = exp [- (kV/Q] 0.32 = exp [-(0.216/day V / 50 m3/day) V = ln (0.32) x 50 m3/day/-0.216/day = 264 m3 Example of Retention Time in a CMFR and PFR • CMFR t = V/Q = 500 m3/50 m3/day = 10 days • PFR t = V/Q = 264 m3/50 m3/day = 5.3 days Homework : Comparison of CMFR and PFR Performance Determine Cout given Cin, V, Q and k • Determine Cout/Cin V = 100 L, Q + 5.0 L/s, k = 0.05/day Determine V, given Cin ,Cout , Q and k • Determine V Cout/Cin = 0.5 Q=5.0 L and k=0.05/s Tantangan Ramadhan 2010 • Juz 30 • Asmaul Husna