Bray team

advertisement

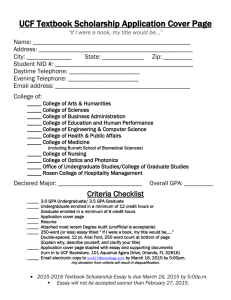

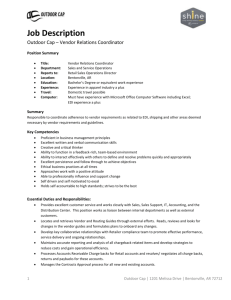

Chapter 5 B2B Strategies From Electronic Data Interchange to Electronic Commerce 2-6-06 Purchasing, Logistics & Support Activities • The potential for cost reductions & business process improvements in these areas are tremendous. • Increase of synergies, which form the basis for 2nd-wave e-commerce opportunities. • An emerging characteristic of these activities is their flexibility. Purchasing Activities • These activities include: – – – – – Identifying vendors Evaluating vendors Selecting specific products Placing orders Resolving issues • In most companies, charged with buying all components at lowest possible price. • Usually more complex than consumer purchasing process. Typical Business Purchasing Process Purchasing Activities (Cont.) • Requires a large number of people to complete the process. • Spend: The total amount of the goods & services that a company buys in a year. • In 2002, Motorola implemented a set of Internet technologies in the procurement operation. – Spend = $48 Billion – Estimate savings of $2.5 Billion by using technologies to accomplish tasks more efficiently & at a lower cost. Direct vs. Indirect Materials Purchasing • Direct Materials – Those materials that become part of the finished product in a manufacturing process – Large Manufacturing Companies have 2 types of direct materials purchasing: • Replenishment/Contract purchasing: The company negotiates long-term contracts for most of the needed materials. • Spot purchasing: The company buys direct materials in a spot market, which is a loosely organized market within a specific industry. • Indirect Materials – Materials & supplies purchases by the company in support of manufacturing an item, but not directly used in production of product. – Often called maintenance, repair, & operating (MRO) supplies Logistics Activities • Classic objective has been to provide the right goods in the right quantities in the right place at the right time. • These activities include: – Managing the inbound movements of materials & supplies – Managing the outbound movements of finished goods & services. • The Internet is providing an increasing number of opportunities to manage these activities better by lowering transaction costs & providing constant connectivity between firms engaged in logistics management. – J. B. Hunt – FedEx Support Activities • These activities include: – Finance & administration – Human resources – Technology departments • Training is another common support activity – By putting training materials on the companies intranet, companies can distribute these materials to many different offices, but continue to be centrally located. • Knowledge management is also being collected using the Internet E-Government • Governments do not typically sell products or services, but they perform many functions for their stakeholders. • Operate businesslike activities: – Employ people – Buy supplies from vendors – Distribute benefit payments • In 2000, U.S. government’s Financial Management Service opened its Pay.gov web site. – Allows site visitors pay taxes & fees using various forms of electronic transfer. • State & local governments are also have web sites that offer services to its citizens. Network Model of Economic Organization • Trend is the shift away from hierarchical structure toward network structures. • Procurement departments are being given new tools to negotiate with suppliers. – The result is alliances & outsourcing contracts. • Highly specialized firms can exist & trade services efficiently using the web. – The network of firms are more flexible & can respond to changes in the economic environment more quickly that hierarchical structured businesses. Electronic Data Interchange • Computer-to-computer transfer of business information between 2 businesses that uses a standard format of some kind. – Information is usually: • Transaction data • Price quotes • Order status inquiries • EDI was first form of e-commerce to be widely used in business. Early Business Information Interchange Efforts • 1950s: Companies began to use computers to store & process internal transaction records, but info flow between businesses used paper – This process was slow, inefficient, expensive, redundant, & unreliable. • 1960s: Businesses began to transfer info on punched cards or magnetic tape – Advances during the ’60s & 70s allowed transfer to occur over telephone lines • 1968: The Transportation Data Coordinating Committee was established. – Explored new ways to reduce the paperwork burden that shippers & carriers faces. – Savings from the reduction of paperwork were significant. Emergence of Broader EDI Standards • American National Standards Institute (ANSI) – Created a set of procedures for the development of national standards & accredit committees that follow those procedures. • 1979: Accredited Standards Committee X12 (ASC X12) established, meets 3 times/year to develop & maintain EDI standards. – Includes standards for specifications for several hundred transaction sets (names of the formats for specific data interchanges) • 1987: United Nations established the EDI for Administration, Commerce, & Transport (UN/EDIFACT) – Designed a common set of standards to be used internationally • 2000: The ASC X12 & UN/EDIFACT agreed to develop one common set, but no date for implementation has been set. Common ASC X12 Transaction Sets Common UN/EDIFACT Transaction Sets How EDI Works • Paper-Based Purchasing Process – No integrated software for internal business processes. – Each step results in production of a paper document, which is delivered by mail, courier or fax to the next department. How EDI Works • EDI Purchasing Process – Mail service replaced by EDI data communication – Paper flows replaced by computers running EDI translation software Value-Added Networks • Trading partners can implement the EDI network & EDI translation process in several ways, but every way uses one of two approaches. • Direct connection EDI: – EDI translator computers at each company are linked directly to each other through modems & dial-up phone lines or leased lines • Indirect connection EDI: – Each company transmits & receives EDI messages through a value-added network (VAN) Direct Connection EDI Indirect Connection EDI through a VAN EDI on the Internet • Trading partners began to view the Internet as a potential replacement for expensive leased lines & slow dial-up connections required for direct & VAN-aided EDI. • Major concerns: – Internet security – Inability to provide audit logs & 3rd party verification Open Architecture of the Internet • Mid-1990s: Many firms began providing EDI services on the Internet (Internet EDI, Web EDI, or open EDI) • Allows trading partners virtually unlimited opportunities for customization of their info interchanges. • Some firms are extending their internal networks to their trading partners, turning intranets into extranets. – Virtual Private Networks (VPN) provides the security that makes this process attractive. Financial EDI • These are EDI transactions that provide instructions to a trading partner’s bank. – EDI-capable banks: those that are equipped to exchange payment & remittance data through VANs. – Value-added banks: those that offer VAN services for non-financial transactions. – Financial VANs: These are not banks but can translate financial transaction sets into ACH formats & transmit them to banks that are not EDI capable. • Reluctant because of perceived low security of Internet Supply Chain Management Using Internet Technologies • Supply chain management: – The process of taking an active role in working with suppliers & other participants in the supply chain to improve products & processes. • Ultimate Goal – To achieve a higher-quality or lower-cost product at the end of the chain Value Creation in the Supply Chain • Business work to establish long-term relationships with a small number of capable suppliers – Known as supply alliances – Key element is trust between the parties • Buyers expect annual price reductions & quality improvements from suppliers at each stage. • Clear communication & quick responses are essential to successful SCM. – Technologies can be very effective communication enhancers. Advantages of Using Internet Technologies • Only disadvantage is the cost of the technologies, but in most cases the advantages provide a greater value that the cost of implementing & maintaining the technologies. Increasing Supply Chain Efficiencies • Many companies are using the Internet and web technologies to manage supply chains in ways that yield increases in efficiency throughout the chain. – Boeing – Dell • Use of technologies result in: – Increased process speed – Reduced costs – Increased flexibility Using Materials-Tracking with EDI & E-Commerce • Integration of use of bar codes & EDI has become prevalent. – Allow companies to scan materials as the are received & to track them as they move from the warehouse to production. • Radio frequency identification devices (RFIDs) – Small chips that include radio transponders – Can be used to track inventory as it moves through an industry value chain – Passive RFID tag: made cheaply, very small, no need for a power source Creating an Ultimate Consumer Orientation in the Supply Chain • A focus on the needs of the consumer who is at the end of an industry value chain. – Companies with long supply chains have problems remembering this focus. • Internet technologies are tools that improve communication at a very low cost. – Ideal aids for enhancing the creation of a highly coordinated & effective supply chain. Building & Maintaining Trust in the Supply Chain • Major issue in building supply chain alliances – Continual communication & information sharing are key elements. • Internet offers new avenues for building trust • Vendors are finding the web provides an opportunity to stay connected with customers more easily & less expensively. • Task of developing info exchange resources that provide supplier performance summaries is a challenge that B2B e-commerce faces. Electronic Marketplaces & Portals • Many business researchers & consultants believed that the Internet would provide an opportunity for companies to establish info hubs for each major industry. • These hubs would be in the form of vertical portals. • Prediction of the success of vertical portals was not completely correct. Independent Industry Marketplaces • These are vertical portals that are focused on a specific industry. • First to open was Chemdex in early 1997 to trade in bulk chemicals. • By mid-2000, more than 2200 independent exchanges were open. – Venture capital funding became scarce & many closed. • By mid 2002, there were fewer than 100 industry marketplaces in operation. • 4 other B2B models arose to take the place of these New B2B Marketplaces • Private Stores – A password protected area of a web site that offers individual customers negotiated price reductions on a limited selection of products & other customized features. • Customer Portals – A corporate web site designed to meet the needs of customers by offering additional services such as private stores, part number cross-referencing, product-use guidelines & safety info. New B2B Marketplaces (Cont.) • Private Company Marketplaces – A marketplace that provides auctions, requests for quotes postings, & other features to companies that want to operate their own marketplace. • Industry Consortia-Sponsored Marketplaces – A marketplace formed by several large buyers in a particular industry. Characteristics of B2B Marketplaces