Week 3 Lecture

advertisement

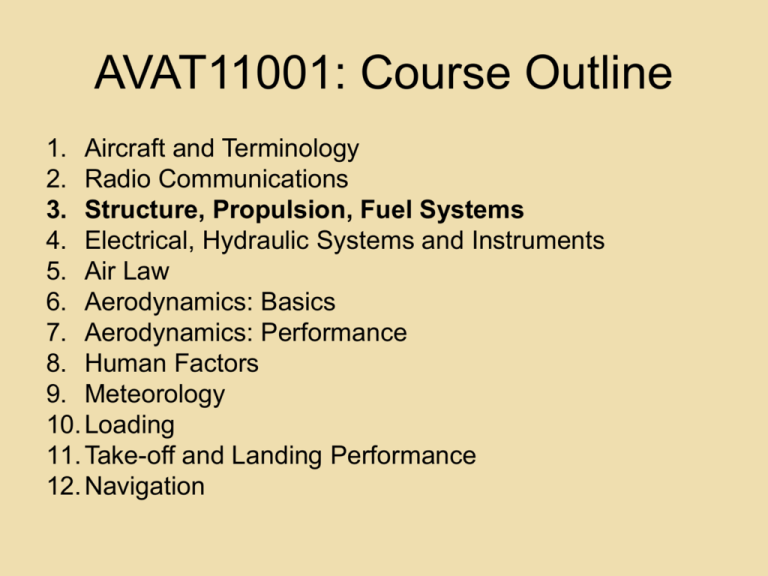

AVAT11001: Course Outline 1. Aircraft and Terminology 2. Radio Communications 3. Structure, Propulsion, Fuel Systems 4. Electrical, Hydraulic Systems and Instruments 5. Air Law 6. Aerodynamics: Basics 7. Aerodynamics: Performance 8. Human Factors 9. Meteorology 10. Loading 11. Take-off and Landing Performance 12. Navigation Stuff to read • Required Reading: BAK Chapter 4, pp. 59105 Questions from the Reading 1. Why does the pilot drain fuel before every flight? 2. Why have two magnetos? 3. What does the mixture control do? 4. Why is an engine lubricated? 5. What is a chock? Structures • An airframe is designed to handle the loads associated with flight – Gravity • Taxi • Landing – Air pressure loads • Level flight • Manoeuvre loads – Propulsion loads • Transmit thrust to the airframe Types of Loads Tension: pulling apart Compression: pushing together (Can cause buckling) Torsion: twisting Shear Stress Bending Moment Basic Structural Components • Most aerospace structures consist of simple light weight designs – See Figure 4-9 page 61 and Figure 4-10 page 62 • Ribs and Frames – Are used to used to define the basic shape • Spars and Longerons – Are used to connect ribs and provide extra strength • Skins and Stringers – Are used to define the final outer mould lines and often carry much of the loads – Stringers are used to connect pieces of skin to each other and the rest of the airframe Rigger’s Angle • Often, the wing is mounted to the fuselage at an angle, such that the chord line is not parallel to fuselage centre line • This is done to provide a desired angle of attack in cruise conditions with the fuselage relatively level – Improves comfort and visibility for pilot • See Figure 4-12 page 63 Walk Around • Prior to flight, you will typically walk around the aircraft to perform a visual inspection of the structure and to insure the vehicle is ready for flight – See Figure 4-21 page 66 • Each aircraft will have a checklist of specific items that you will inspect – The checklist of a Cessna 172 is included in these notes as an example Cessna 172 Pre Flight Inspection Checklist • Cabin – – – – – – • Control Wheel Lock -- REMOVE Ignition Switch -- OFF. Master Switch -- ON. Fuel Quantity Indicators – CHECK QUANTITY Master Switch -- OFF Baggage Door – CHECK, lock with key if child’s seat is to be occupied. Left Wing Trailing Edge – • Aileron - - CHECK for freedom of movement and security. Left Wing – – – – • Main Wheel Tyre - - CHECK for proper inflation. Before first flight of the day and after each refueling, use sampler cup and drain small quantity of fuel from fuel tank sump quick-drain valve to check for water, sediment and proper fuel grade. Fuel Quantity - - CHECK VISUALLY for desired level. Fuel Filler Cap - - SECURE. Left Wing Leading Edge – – – Pitot Tube Cover - - REMOVE and check opening for stoppage. Fuel Tank Vent opening - - CHECK for stoppage. Stall Warning Opening - - CHECK for stoppage. To check the system, place a clean handkerchief over the vent opening and apply suction; a sound from the warning horn will confirm system operation. Cessna 172 Pre Flight Inspection Checklist, Continued • Nose – – – – – – – – Engine Oil Level – CHECK. Do not operate with less than six quarts. Fill to eight quarts for extended flight. Before first flight of the day and after each refueling, pull out strainer drain knob for about four seconds to clear fuel strainer of possible water and sediment. Check strainer drain closed. If water is observed, the fuel system may contain additional water, and further draining of the system at the strainer, fuel tank sumps, and fuel selector valve drain plug will be necessary. Propeller and Spinner - - CHECK for nicks and security. Landing Light(s) - - CHECK for condition and cleanliness. Carburetor Air Filter - - CHECK for restrictions by dust or other foreign matter. Nose Wheel Strut and Tyre - - CHECK for proper inflation. Nose Tie-Down - - DISCONNECT. Flight Instrument Static Source Opening (left side of fuselage) - CHECK for stoppage. Cessna 172 Pre Flight Inspection Checklist, Continued • Right Wing – – – – – • Wing Tie-Down – DISCONNECT. Main Wheel Tire --- CHECK for proper inflation. Before first flight of the day and after each refueling, use sampler cup and drain small quantity of fuel from fuel tank sump quick-drain valve to check for water, sediment, and proper fuel grade. Fuel Quantity -- CHECK VISUALLY for desired level. Fuel Filler Cap – SECURE. Right Wing Trailing Edge – • Aileron – CHECK freedom of movement and security. Empennage – – – Rudder Gust Lock – REMOVE Tail Tie – Down -- DISCONNECT Control Surfaces – CHECK freedom of movement and security Engine • What is an engine? What does it do for an aircraft? – The primary purpose of the engine is to convert chemical energy (fuel) into mechanical energy (kinetic) to generate thrust. • There are 2 main types of engines used in aircraft – Piston engines (used to drive propellers) – Turbine engines How do piston engines work? • Piston engines operate on principles that govern the behaviour of gases – Charles’ Law, Boyle’s Law, etc • A spark is used to burn fuel and increase the temperature of gases in a cylinder • When the temperature of a gas is raised, the pressure is increased • This increase in pressure can be used to do work – See Figure 4-27 page 69 Ignition • In order to get the fuel to combust in a controlled fashion, it must be lit at the right time. • The fuel in the cylinder is ignited by an electrical spark that is provided by a spark plug. • The electrical energy required to cause a spark is provided by magnetos • See Figure 4-29 page 70 Dual Ignition Systems • Most modern aircraft have dual ignition systems on their piston engines – Provides safety – Improves fuel efficiency • When starting an aircraft it is important to verify that both ignition systems are working correctly – See Figures 4-31 and 4-32 page 71 – When a particular magneto is turned off, you should notice a slight drop in engine RPM Carburettor • The carburettor mixes the fuel with air so that this mixture will burn well in the engine • Automobile engines have carburettors that are designed to provide the proper fuel-to-air ratio on an standard day • Aircraft engines are exposed to a greater variety of pressures and densities than automobiles, and the pilot needs to be able to change the carburettor to maximize fuel efficiency Mixture Control • The amount of air flowing through the carburettor is a function of the density of the air outside the aircraft and the engine RPM • Density, in general, decreases with altitude • To keep the engine running efficiently, the pilot will change the amount of fuel being mixed with the air as the density changes – See Figure 4-35 page 75 Engine Oil • 5 Functions of Engine Oil – Lubrication – Cooling – Cleaning – Sealing – Protecting • It is better to run an engine with bad oil than no oil at all Propellers • Propellers generate thrust the same way the wings generate lift – They create a pressure differential when they are moved through the air • All propellers are very expensive because they are very precisely manufactured • There are 2 main types – Fixed pitch – Variable pitch • Fixed pitch propellers are mechanically simple • Variable pitch propellers involve complex machinery and are heavier than fixed pitch propellers – The advantage of a variable pitch propeller is that it can provide improved fuel efficiency by allowing the engine to operate at a more efficient RPM Fuel Systems • See Figures 4-62 and 4-63 on page 101 • 2 Basic types – Gravity-feed – Pressure-feed • Vents and drain valves are important to check fuel and equalize pressure in the tanks • Be aware that fuel gauges are: – Not very accurate – Affected by aircraft attitude • Always visually inspect the tanks before flight – Proper quantity – Impurity free – Condensation check • Only use the proper grade of fuel – If you put the wrong type of fuel in, expect something bad to happen For next week… • Required Reading: BAK Chapter 4, pp. 106-132