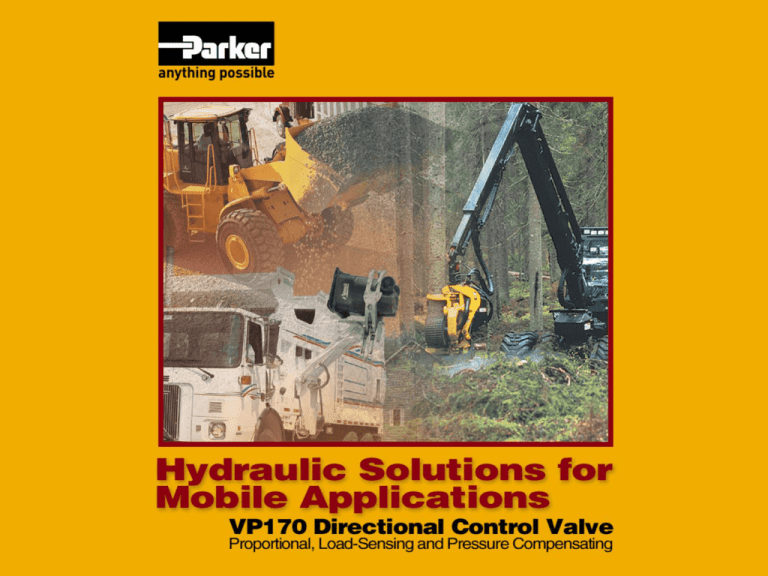

VP170 PowerPoint - Western Integrated Technologies

advertisement

Click here to add Company Name and Date Parker is the global leader in motion and control technologies, partnering with its customers to increase their productivity and profitability. 2 Load-Sense Pressure Compensated Valve with Flow-Sharing (Post-Compensated) • 3rd Generation post-compensated valve • Target Launch – October 2006 3 Specifications • Flows – Pump input up to 60 GPM – Work sections up to 50 GPM • Pressure 5000 PSI • Sectional construction • Max. porting – Inlet SAE 16 top and side – Work SAE 12 – Outlet SAE 16 top and SAE 20 side 4 Model Logic V = valve P = lspc (post-compensated) 170 = max work section flow in LPM Remember the VO40: V = valve O = open center 40 = max work section flow in plum 5 Key Features & Benefits • Flow-sharing for improved productivity, safety and operator comfort • Load-sense pressure compensated for improved system efficiency and fuel savings • Modular design enables better match between cost and value. Available with: – Load-sense pressure compensated, with or without induced load protections – Load-sense only • Low loop pressure drops for reduced HP consumption • Low pressure regeneration to solve cavitation problems of premature component failure and “spongy” operation 6 Key Market Drivers • Improved machine controllability and productivity • Horsepower utilization, due tier II and III engines • Fuel cost 7 Target Markets • Wheel loaders and dozers – Launched to Deere September 2004 for J Series Loaders • Cranes • Forestry – loaders, feller-bunchers, harvesters, forwarders, skidders • Refuse – side loaders • Snow and ice • Distribution 8 Competitors • Post-Compensated – Danfoss – PVG100 – Husco – SX180 (new) (new) – Rexroth – SX14? – Rexroth - M4-15 (have not seen in dist’n channel) (120 lpm out of work section) • Pre-Compensated – MP18 and MP22 (being discontinued; Wooster closing) 9 Flow-Sharing Adjusts to a pump over-demand conditions by reducing the flow to the selected functions, while maintaining the speed relationship between those functions The benefit - the operator can maintain the control of the machine The result - increased productivity, improved safety and operator comfort 10 Flow-Sharing Example #1 Max Pump Flow 40 gpm WS 1 WS 2 28 gpm 12 gpm Scenario #1 - operator wants more speed from WS 1 WS 1 WS 2 Req Pump Req Flow Req Flow Flow 34 gpm 12 gpm 46 gpm Overdemand = 40/46 = .87, so reduce flows by 13% Actual WS Flow .87 x 34 gpm for WS 1 .87 x 12 gpm for WS 2 WS 1 WS 2 Max Pump Flow 29.6 gpm 10.4 gpm 40 gpm 11 Flow-Sharing - Example #1 Full pump flow is 40 GPM, but operator wants 46 GPM 34 35 30 29.6 28 25 GPM 20 15 12 12 10.4 10 5 0 Work section flows at full pump displacement of 40 GPM Operator wants 40 GPM from two work sections But now operator wants 46 GPM 12 Only 40 GPM available, so valve goes into overdemand and divides the pump flow accordingly Flow-Sharing - Example #2 Max Pump Flow 40 gpm WS 1 WS 2 28 gpm 12 gpm Scenario #2 - engine rpm's decrease Max Pump Flow 30 gpm Overdemand = 30/40 = .75, so reduce flows by 25% Actual WS Flow .75 x 28 gpm for WS 1 .75 x 12 gpm for WS 2 WS 1 WS 2 21 gpm 9 gpm 13 Flow-Sharing - Example #2 Engine RPM decreases flow from 40 GPM to 30 GPM 30 28 25 21 GPM 20 15 12 9 10 5 0 Work section flows at full pump displacement of 40 GPM Operator wants 40 GPM from two work sections Engine rpm’s drop so max pump flow is 30 GPM; valve divides the flow accordingly 14 Improved Efficiency of PCLS 60 50 40 F l 30 o w 20 Wasted power L.S. system Power consumed by function 10 0 0 500 1000 1500 2000 2500 Pressure 15 3000 3500 Improved Efficiency of PCLS “A big reason for the change by Deere was mounting fuel costs. The pressure compensated load-sensing variable displacement system is a lot more fuel efficient than the open-center system, depending on operation, by as much as 30, 40, or even 50% better,” says Anders Lindstrom, Senior Systems Engineer with Parker Hannifin. “With the fuel savings I get on two of my 437Cs, I can make the payment on one.” 16 Modular Design Offers Three Circuit Options Induced load/ transition ck Compensator 1. Load-sense pressure compensated (PCLS) with induced load protection Compensator 2. Load-sense pressure scompensated (PCLS) w/o induced load protection Load sense ck for all circuit options located between the work ports!!! 17 Modular Design Offers Three Circuit Options Transition ck 3. Load-sense only Load sense ck for all circuit options located between the work ports !!! 18 Circuit – PCLS with Induced Load Protection Pressure compensated load-sense (PCLS) w/ reverse flow check 19 Circuit – PCLS without Induced Load Protection Pressure compensated load-sense (PCLS) w/o reverse flow check 20 Circuit – LS only Load-sense valve circuit 21 Low Loop Pressure Drop Ports A/B - tank Workport to Tank Delta P - Section #2 Flow (lpm ) 0.0 50.0 100.0 150.0 200.0 250.0 300.0 300 20.0 250 VG20 & V40 V42 15.0 150 10.0 VP170 100 5.0 VG35 50 0 0.0 0 10 20 30 40 50 Flow (gpm ) 22 60 70 80 90 Pressure (bar) Pressure (psi) 200 Spool Options • Types – 3 way cylinder and motor – 4 way cylinder and motor – 4 position float • Flows – Flow limited at full stroke and 250 PSI margin • GPM 8, 16, 24, 32, 45 • Additional flow limitation can be achieved with spool stroke limiters for ports A or B or both. Applies to hydraulic remote and solenoid operated. – Not flow limited • Another spool available that falls off the notch at full stroke and will try to output the full pump flow 23 Inlet Options 24 Inlet Options 25 Outlet Options 26 Low Pressure Regeneration • Low pressure regeneration – Addresses cavitation • Cavitation wreaks havoc on hydraulic components and results in spongy machine operation • During valve operation, the valve will sense if a function is cavitating and will force oil across anti-cavitation checks to fill void • If there is still a void in the hydraulic loop, when spools returned to neutral – will keep pump on stroke until a specified pressure level is achieved in the loop 27 Robust • Endurance and fatigue testing: – Inlet, work sections and outlet fatigue tested @ 6250 PSI and 3M cycles – NO FAILURES – Load-sense checks endurance tested @ 5000 PSI and 2M cycles – NO FAILURES – Transition/induced load check tested @ 5000 PSI and 1M cycles – NO FAILURES 28 Performance Enhancement • Meter-out control can increase P-A/B pressure drop, when opposite port energized • Work section body lengthened to ensure that pressure drop P/A-B not affected when meter-out control required Port B 29 Tank Performance Enhancement • 4-position float work section – When work section is in the float position, traditional design will draw oil A and B tank cores • VP170 design can draw oil from: – Tank cores of ports A and B – Return flow from port B • This improves float down time and addresses potential cavitation 30 Additional Benefits • Fly cut lands each critical area (10) means consistent metering from valve to valve • Uses same spool positioners as VA20 and PC25 — reduces cost, risk and improves delivery • Uses same port accessories as FIVE other valve series –– reduces cost, risk and improves delivery • Spool stroke of .406" longest in industry — this means more metering vs. spool stroke • One solenoid used for on/off and proportional applications 31 Summary • • • • • • • • • • • • • Pressures to 5000 PSI Flow range is 8-55 gpm out of the work port Flow-sharing Circuit options – load-sense pressure compensated or load-sense Optional induced load protection Optional low pressure regen and void filling scheme Improved filling scheme during float position (4 position float work section) Flexible, compact and cost effective EH package Symmetrical spool for easy conversion to right or left-handed sections Same spool positioners and port accessories as open-center counterparts Stroke limiters available for hydraulic remote and solenoid operation Full complement of flow-limited spools available Easily serviceable — all checks located on top of work section 32 VP170 Product Launch • Literature – Product Catalog HY14-2006/US – Overview Bulletin HY14-2006/US – Service Bulletin HY14-2006-M1/US – Catalog CD HY14-2006/US – Advertisement – Product Bit – News Release – To order call 1-800-CPARKER 33 Hydraulic Valve Solutions For Mobile & Truck Applications • http://www.parker.com/hydraulicvalve – Complete product information – Applications – Systems and subsystems 34 Contact Us • Phone: 440-366-5200 • Fax: 440-366-5253 • Local Parker Distributor www.parker.com/hydraulicvalve 35 Parker, your single source for all your Hydraulic Valve Solutions. Thank You! 36