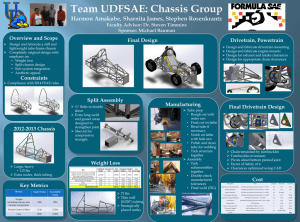

Team F13-60-Baja Frame Design

advertisement

TEAM F13-60-BAJA FRAME DESIGN Design Review Members: Austin Lewandowski (PM) Steven Baldwin Preston Mathis Keegan Lohman Thang Tran Kyle Koester F13-60-Baja Design Review Agenda Design Presentation o Customer demands (Explain some of the requirements of SAE competitions which limit certain aspects of the car’s design) House of Quality o The design of the frame at this point in time (State of project) FEA Frame design Material selection Cost Considerations/Funding Anticipated Design completion/Project completion Questions for Faculty Comments/Suggestions Closing Remarks Project Overview • Building an off road vehicle to SAE specs, with intent to sell to general public • Using last years suspension geometry • Targeting weight loss for the car • Accomplishing goals through Finite Element Analysis (FEA), material selection, and improved frame design 3 9 Marketability 5 Weight 4 Durability 3 1 3 1 Performance 3 3 57 3 1 Tech Importce. 9 3 9 Rural King Go Cart 5 Polaris Razor Safety Saluki Eng. Co 3 Geometry/ Des. 9 FEA Design Quality 2 Mat. Selection Dimensions Size Cost Import 1-5 House of Quality 3 9 3 2 3 9 1 9 9 5 4 2 4 3 3 9 3 2 3 3 9 9 5 3 1 3 5 2 9 57 150 51 108 90 50 Finite Element Analysis • Performing static analysis, and dynamic loading of frame during impact • In process of learning FEA software (Inventor) • Several transient models researched that we can modify • samples from auto industry • Examples from other SAE Baja teams Similar Vehicles • Consistent top 5 finisher in SAE series (durable and lightweight) 2010 Polaris RZR trailing arm rear end Frame Design • Reproduced front end: Re-designed rear roll hoop and base frame 4130 Chromoly [1] 4130 (Chromoly) Normalized Alloy Steel • The material selected for the use of this years SAE baja frame will be 4130 “chromoly” steel. Although it is more expensive than typical 1018 steel, the durability, ease of welding, and superior strength to weight ration makes it a prime material for off-road applications. A majority of other teams use this material and have had great success in past competitions. Chromoly is an abbreviation for chromium, molybdenum steel. It is not as lightweight as aluminum alloys, but has the advantages of high tensile strength and malleability. It is also easily welded and is considerably stronger and more durable than standard 1020 steel tubing. [1] 4130 (Chromoly) Normalized Alloy Steel [Internet] OnlineMetals.com, 2013, http://www.onlinemetals.com/alloycat.cfm?alloy=4130, [10/24/13]. Ultimate Tensile Strength, psi 97,200 Yield Strength, psi 63,100 Elongation 25.5% Rockwell Hardness B92 Chemistry Iron (Fe) 97.3 - 98.22% Carbon (C) 0.28 - 0.33% Chromium (Cr) 0.8 - 1.1% Manganese (Mn) 0.4 - 0.6% Molybdenum (Mo) 0.15 - 0.25% Phosphorus (P) 0.035% max Sulphur (S) 0.04% max Silicon (Si) 0.15 - 0.35% Questions • Do the dynamics of the car still need to be analyzed when the • • • • goal of our design is to simply reduce the overall car weight? What are specific considerations when analyzing the dynamics of the frame (FEA)? Are there any more efficient methods to reduce weight? What gaps do you see in our FEA/design model that could make a difference? What are the keys to writing an outstanding final proposal?