Oxidative coupling of methane

advertisement

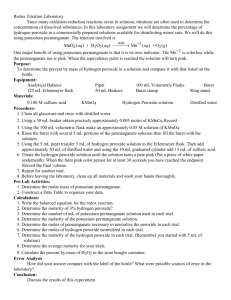

Oxidative coupling of Methane & other reactions for treating Sulfur CHBE 446 – Gp5 Stephan Donfack Benjamin Harbor Nguyen Huynh Cyndi Mbaguim AGENDA • Introduction Source of Methane and Sulfates in marine environment • Anaerobic oxidation of Methane Mechanism & Syntrophy • Treatments of Sulfur derivative Hydrogen peroxide Metal Salts & Potassium Permanganate INTRODUCTION • Sea floor and microbial inhabitants have an important role in the biogeochemical cycling of elements. • Different gases found in marine environment: Methane 5070%, Carbon dioxide 30-50%, trace gases (nitrogen, ammonia, and hydrogen sulfide) • Carbon mineralization process through anaerobic oxidation of Methane which is generally coupled to sulfate reduction leads to sulfur derivatives -SO42-+ CH4 (organic matter) HS2-+ H2O + HCO3ΔG°’= –16.6 kJ.mol–1 • Hydrogen Sulfide is a notorious gas among sulfur derivatives: Corrosion to concrete and metal pipes Odorous (recognition at 4.5 ppb) Health concerns (10 ppmV and death at 600 ppmV) Combustion and acid rains Ozone depletion Total sulfide at 90-250mg-S/L, inhibits methanogenesis • The removal of H2S is immediately recommended to protect downstream equipments. • This removal is done through different processes or reactions. Anaerobic Methane Oxidation(AMO) • Little methane escapes from anoxic sediment to the water column and atmosphere • This postulates that methane is somehow consumed by microbes • Recent studies reveals that these micro-organisms undergo anaerobic oxidation, as they consume methane • Methanotrophs are aerobic bacteria: 𝐶𝐻4 + 2𝑂2 → 𝐶𝑂2 + 2𝐻2 𝑂 • So what favors the anaerobic oxidation? SULFATES EVIDENCE • In cold seep areas, thermodynamic and kinetic conditions favor sulfate reduction over methanogenesis Sulfate reduction rate are extremely high Sulfate concentrations decrease with sediments depths matched by upward depletion of methane • This provides confirmation that there is a link between methane and sulfate turnover MECHANISM 1. Reverse Methanogenesis : Energetically favorable only if CO2 , H2O are rapidly removed. C𝐻4 + 2H2 O → 4H2 + CO2 𝑪𝑯𝟒 + 𝟐𝑯𝟐 𝑶 → 𝟒𝑯𝟐 + 𝑪𝑶𝟐 2. Sulfate-reducing bacteria convert sulfate to sulfite in the presence of H2 product from “1” − 𝑯𝟒 +𝟒𝑯𝟐 + 𝑺𝑶𝟐− 𝟒 → 𝑯𝑺 + 𝟒𝑯𝟐 𝑶 3. Overall “syntrophy” reaction − 3𝑪𝑯𝟒 +𝑺𝑶𝟐− 𝟒 → 𝑯𝑺 + 𝑯𝟐 𝑶 + HCO *** 𝑯𝑺− converts to sulfites, sulfides, sulfates derivatives 𝐻4 +4𝐻2 + 𝑆𝑂42− → 𝐻𝑆 − + 4𝐻2 𝑂 Chemicals Which Have Been Tried to Control Hydrogen Sulfide • Hydrogen Peroxide • Chlorine • Metal Salts • Potassium Permanganate Hydrogen Peroxide • Hydrogen peroxide reacts with hydrogen sulfide under acid, neutral and alkaline conditions. • The reaction is accelerated by increasing temperature and/or the addition of catalysts such as iron. • Stoichiometry is also affected by pH. • Under acidic or neutral conditions the reaction with hydrogen peroxide produces sulfur and water: H2S + H2O2 → S + 2 H2O Since waste streams often contain other reactive materials, it may be necessary to add more than the stoichiometric amount of hydrogen peroxide. • In alkaline solution (> pH 8), the dominant reaction is: Na2S + 4 H2O2 → Na2SO4 + 4 H2O The 4/1 wt. ratio of H2O2/Sulfide can be lowered by using a combination of air and hydrogen peroxide. Chlorine • Chlorine has been applied to wastewater in a dose that is at least three to nine times the concentration of sulfide to be oxidized. Chlorine combines with water to form hypochlorous and hydrochloric acids. Disadvantages: Chlorine kills the natural (and Clear-Flo®) wastedegrading bacteria. Chlorine combines with the urine in the waste stream to form chloramines, which are difficult to remove. Toxic or carcinogenic chlorinated hydrocarbons may form during treatment. Chlorine is a hazardous material, requiring special safety precautions. Metal Salts • By reacting certain metal salts, such as ferrous sulfate, with hydrogen sulfide, an insoluble metallic sulfide will be formed. The dose is 4.5 grams of ferrous sulfate for each gram of sulfide to be oxidized. This is less expensive than peroxide or chlorine. Disadvantages: These products may contain a high free acid content which causes detrimental changes in the pH and alkalinity of the stream, which can interfere with biodegradation of the waste. Potassium Permanganate • Potassium permanganate is a strong oxidizing agent that can react with hydrogen sulfide in a variety of ways. • In acidic conditions, the following reaction takes place: Hydrogen sulfide + Potassium permanganate Element sulfur + Water + Potassium hydroxide + manganous oxide. 3H2S + 2KMnO4 3S + 2H2O + 2KOH + 2MnO2 Potassium Permanganate (cont’d) Under alkaline conditions the following takes place: Hydrogen sulfide + Potassium Permanganate Potassium sulfate + manganous oxide + potassium hydroxide + water. 3H2S + 8KMnO4 3K2SO4 + 8MnO2 + 2KOH + 2H2O. Under conditions that are in between acidic and alkaline pHs, a variety of reactions occur, yielding elemental sulfur, sulfate, thionates, dithionates and manganese sulfide end products. Potassium Permanganate (cont’d) Disadvantages: Dosages are difficult to predict and control in most liquid applications. The high cost and high dose, 6 or 7 parts of potassium permanganate are needed for each part of hydrogen sulfide, are discouraging. Safety precautions are required for handling and storage. Summary REFERENCES 1. V.A. Edwards, C.P. Velasco, K.J. Edwards, "Hydrogen Sulfide-The Relationship of Bacteria to its Formation, Prevention, and Elimination." Alken Murray Corp. Web Feb 4. 2014 2. http://alrlab.pdx.edu/courses/Anaerobic%20Methane%20Oxidation %20Presentation.pdf